High-toughness TPU-based 3D printing material and preparation method and application thereof

A 3D printing, high toughness technology, applied in the field of 3D printing materials, can solve the problems of unsatisfactory strength and toughness, and achieve the effect of good flame retardancy and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

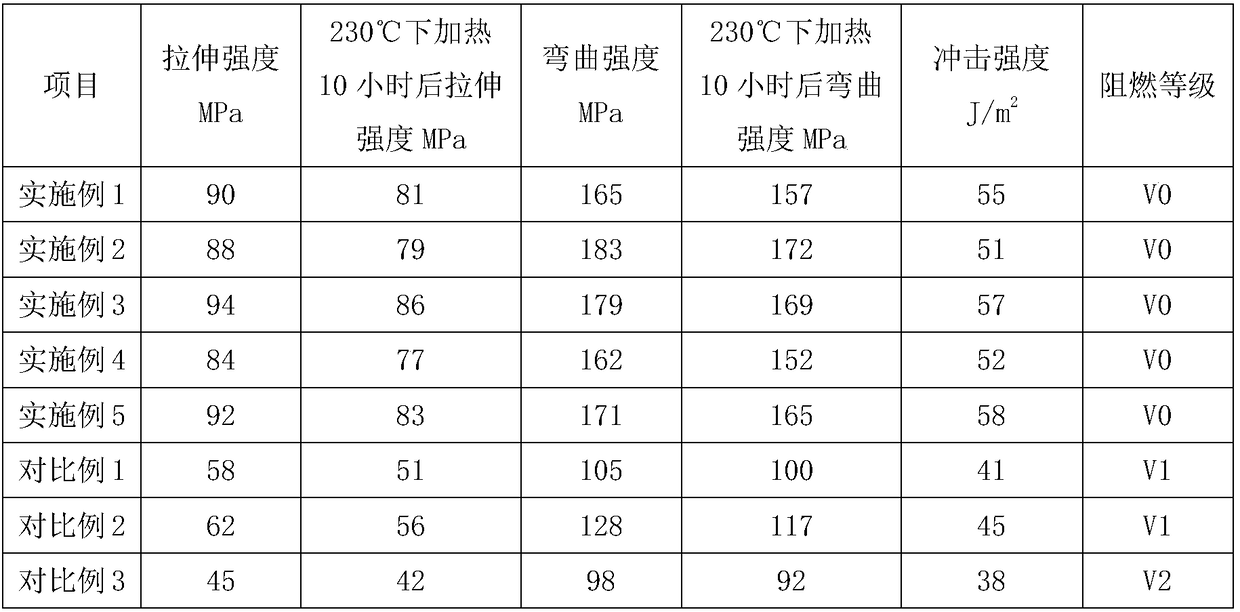

Examples

Embodiment 1

[0020] A high-toughness TPU-based 3D printing material. The high-toughness TPU-based 3D printing material includes the following parts by weight of raw materials: 115 parts of TPU, 15 parts of divaleryl diboron, 12 parts of zinc hyaluronate, and 12 parts of chitosan , 6 parts of tetrachlorophthalic acid, 4 parts of manganese tetroxide, 3 parts of rectorite powder.

[0021] A preparation method of high toughness TPU-based 3D printing material, the steps are:

[0022] (1) Place the zinc hyaluronate in 35 parts of water, stir and dissolve to obtain the zinc hyaluronate solution, for later use;

[0023] (2) Add chitosan to the zinc hyaluronate solution and stir to dissolve to obtain a mixed solution;

[0024] (3) Mix divaleryl diboron, tetrachlorophthalic acid and 25 parts of methyl dihydrojasmonate, and stir for 1.8 hours at 125°C. Add trimanganese tetroxide and stir at 100°C. Reaction 2.6h;

[0025] (4) Mix the mixed solution obtained in step (2) with rectorite powder, and after stirrin...

Embodiment 2

[0028] A high-toughness TPU-based 3D printing material. The high-toughness TPU-based 3D printing material comprises the following parts by weight of raw materials: TPU 205 parts, divaleryl diboron 26 parts, zinc hyaluronate 17 parts, and chitosan 16 parts , 14 parts of tetrachlorophthalic acid, 9 parts of manganese tetroxide, 8 parts of rectorite powder.

[0029] A preparation method of high toughness TPU-based 3D printing material, the steps are:

[0030] (1) Place the zinc hyaluronate in 58 parts of water, stir and dissolve to obtain the zinc hyaluronate solution, for later use;

[0031] (2) Add chitosan to the zinc hyaluronate solution and stir to dissolve to obtain a mixed solution;

[0032] (3) Mix divaleryl diboron, tetrachlorophthalic acid and 40 parts of methyl dihydrojasmonate, stir for 1.8h at 143℃, add trimanganese tetroxide, and stir at 120℃ Reaction 2.6h;

[0033] (4) Mix the mixed solution obtained in step (2) with rectorite powder, and after stirring uniformly, add the ...

Embodiment 3

[0036] A high-toughness TPU-based 3D printing material, which comprises the following parts by weight of raw materials: 172 parts of TPU, 20 parts of divaleryl diboron, 15 parts of zinc hyaluronate, and 14 parts of chitosan , 10 parts of tetrachlorophthalic acid, 6 parts of manganese tetroxide, 6 parts of rectorite powder.

[0037] A preparation method of high toughness TPU-based 3D printing material, the steps are:

[0038] (1) Place the zinc hyaluronate in 45 parts of water, stir and dissolve to obtain the zinc hyaluronate solution, for later use;

[0039] (2) Add chitosan to the zinc hyaluronate solution and stir to dissolve to obtain a mixed solution;

[0040] (3) Mix divaleryl diboron, tetrachlorophthalic acid and 30 parts of methyl dihydrojasmonate, and stir for 1.8h at 135°C. Add trimanganese tetroxide and stir at 110°C. Reaction 2.6h;

[0041] (4) Mix the mixed solution obtained in step (2) with rectorite powder, and after stirring uniformly, add the product obtained in step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com