High-viscosity asphalt and preparation method thereof

A technology of high-viscosity asphalt and matrix asphalt, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of uneven product quality, limited application of drainage pavement, and high price, so as to reduce processing difficulty and improve asphalt The effect of insufficient adhesion and difficulty in segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

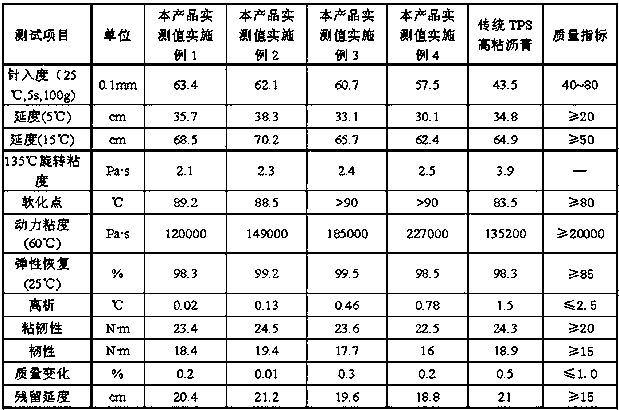

[0032] Example 1 A high-viscosity asphalt is composed of the following raw materials in weight percentage (kg / kg): 3.2% styrene-butadiene-styrene block copolymer (SBS), styrene-butadiene rubber ( SBR) 2.4%, compatibilizer 2.3%, stabilizer 0.08%, sodium dodecyl sulfonate 2%, polyphosphoric acid (PPA) 1.5%, No. 70 base asphalt 88.52%.

[0033] The preparation method of this high-viscosity asphalt comprises the following steps:

[0034] (1) Weighing according to the proportion;

[0035] (2) Heat and melt the base asphalt at 135°C, raise the temperature to 150°C, add a compatibilizer, stir at a speed of 100r / min for 5 minutes to mix evenly, and obtain mixture A;

[0036] (3) Heat up mixture A to 160°C, add styrene-butadiene-styrene block copolymer (SBS), styrene-butadiene rubber (SBR), sodium dodecylsulfonate, polyphosphoric acid (PPA), and heat at 200r Stir for 10 minutes at a speed of 1 / min, make it fully swell and mix evenly, and obtain mixture B;

[0037] (4) Mixture B is s...

Embodiment 2

[0040] Example 2 A high-viscosity asphalt is composed of the following raw materials in weight percentage (kg / kg): styrene-butadiene-styrene block copolymer (SBS) 4.1%, styrene-butadiene rubber ( SBR) 2%, compatibilizer 3.4%, stabilizer 0.1%, sodium dodecyl sulfonate 1.6%, polyphosphoric acid (PPA) 1.3%, No. 70 base asphalt 29.2%, No. 90 base asphalt 58.3%.

[0041] The preparation method of this high-viscosity asphalt comprises the following steps:

[0042] (1) Weighing according to the proportion;

[0043] (2) Heat and melt the base asphalt at 135°C, heat up to 150°C, add compatibilizer, stir at a speed of 100r / min for 6 minutes to mix evenly, and obtain mixture A;

[0044] (3) Heat up mixture A to 160°C, add styrene-butadiene-styrene block copolymer (SBS), styrene-butadiene rubber (SBR), sodium dodecylsulfonate, polyphosphoric acid (PPA), and heat at 200r Stir for 10 minutes at a speed of 1 / min, make it fully swell and mix evenly, and obtain mixture B;

[0045] (4) Mixtu...

Embodiment 3

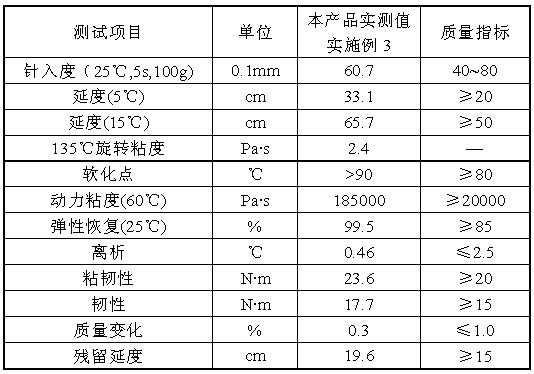

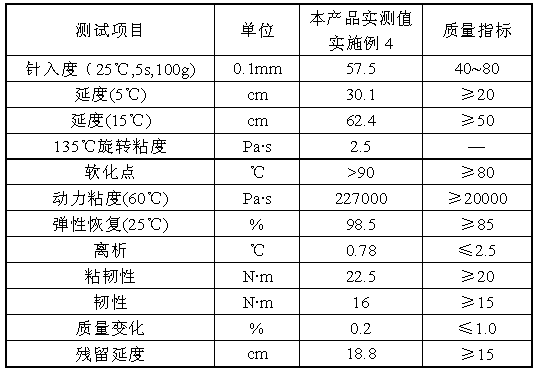

[0048] Example 3 A high-viscosity asphalt, the high-viscosity asphalt is composed of the following raw materials in weight percentage (kg): styrene-butadiene-styrene block copolymer (SBS) 4.7%, styrene-butadiene rubber (SBR) 1.8%, compatibilizer 3.7%, stabilizer 0.2%, sodium dodecyl sulfonate 1.4%, polyphosphoric acid (PPA) 1.2%, No. 70 base asphalt 17.4%, No. 90 base asphalt 69.6%.

[0049] The preparation method of this high-viscosity asphalt comprises the following steps:

[0050] (1) Weighing according to the proportion;

[0051] (2) Heat and melt the base asphalt at 135°C, raise the temperature to 150°C, add a compatibilizer, stir at a speed of 100r / min for 8 minutes to mix evenly, and obtain mixture A;

[0052] (3) Heat up mixture A to 160°C, add styrene-butadiene-styrene block copolymer (SBS), styrene-butadiene rubber (SBR), sodium dodecylsulfonate, polyphosphoric acid (PPA), and heat at 200r Stir for 10 minutes at a speed of 1 / min, make it fully swell and mix evenly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com