A high-performance antifouling and easy-to-clean film and its preparation method

A clean film, high-performance technology, applied in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the problems of low film strength, poor friction resistance and washing resistance, and weak adhesion And other problems, to achieve the effect of stable chemical performance, good washing resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

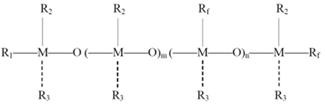

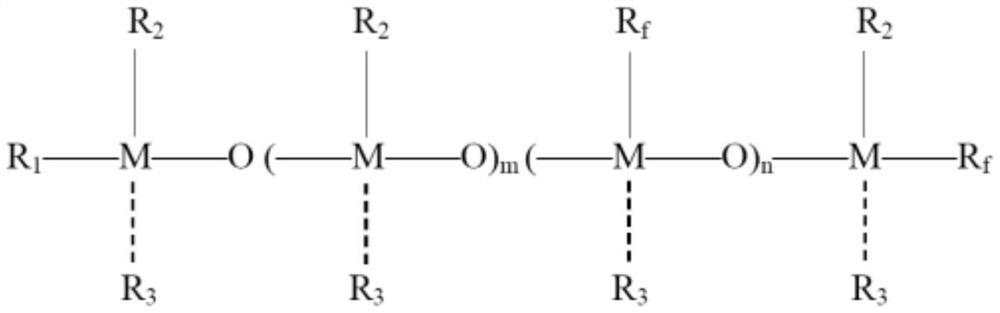

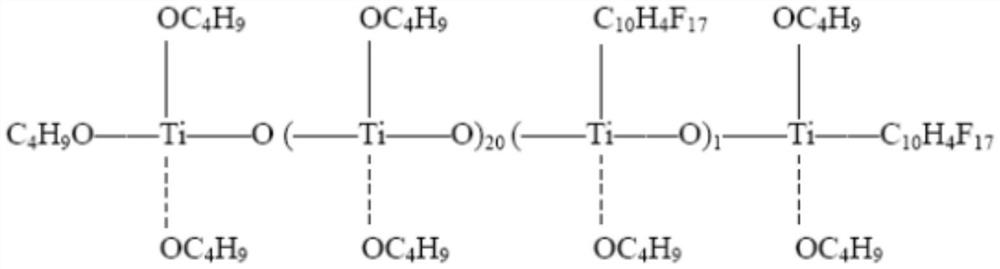

[0028] Add 10 parts of water + 75 parts of ethanol into the reaction kettle, add glacial acetic acid dropwise to adjust the pH to 3.7, add 10 parts of inorganic-organic hybrid polymer and 3 parts of n-butyl titanate, and stir evenly. Get an anti-fouling, easy-to-clean coating solution. The coating liquid obtained above was uniformly coated on the surface of the glass substrate (2mm thick soda lime glass) by spraying method, and was cured in an oven at 150° C. for 10min, and the film thickness was about 10nm. The structural formula of the inorganic-organic hybrid polymer was: :

[0029]

Embodiment 2

[0031] Add 20 parts of water + 39 parts of ethanol into the reaction kettle, add hydrochloric acid dropwise to adjust the pH to 2.5, add 30 parts of inorganic-organic hybrid polymer and 10 parts of methyl orthosilicate, and stir evenly. Get an anti-fouling, easy-to-clean coating solution. The coating liquid obtained above was evenly coated on the surface of the glass substrate (2mm thick soda lime glass) by spraying, and cured in an oven at 150°C for 10min, with a film thickness of about 35nm. The structural formula of the inorganic-organic hybrid polymer is :

[0032]

Embodiment 3

[0034] Add 15 parts of water + 67 parts of ethanol into the reaction kettle, add nitric acid dropwise to adjust the pH to 1.8, add 20 parts of inorganic-organic hybrid polymer, 7 parts of tetra-n-propyl zirconate, and stir evenly. Get an anti-fouling, easy-to-clean coating solution. The coating liquid obtained above was evenly coated on the surface of the glass substrate (2mm thick soda lime glass) by spraying, and cured in an oven at 150°C for 10min, with a film thickness of about 22nm, wherein the inorganic-organic hybrid polymer has the structural formula of :

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com