Wolfberry fermented wine and preparation method thereof

A technology of fermenting wine and wolfberry, which is applied in the field of wine making, can solve the problems of short shelf life, uncoordinated wine body color, etc., and achieve the effect of high utilization rate of raw materials, wide application population and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

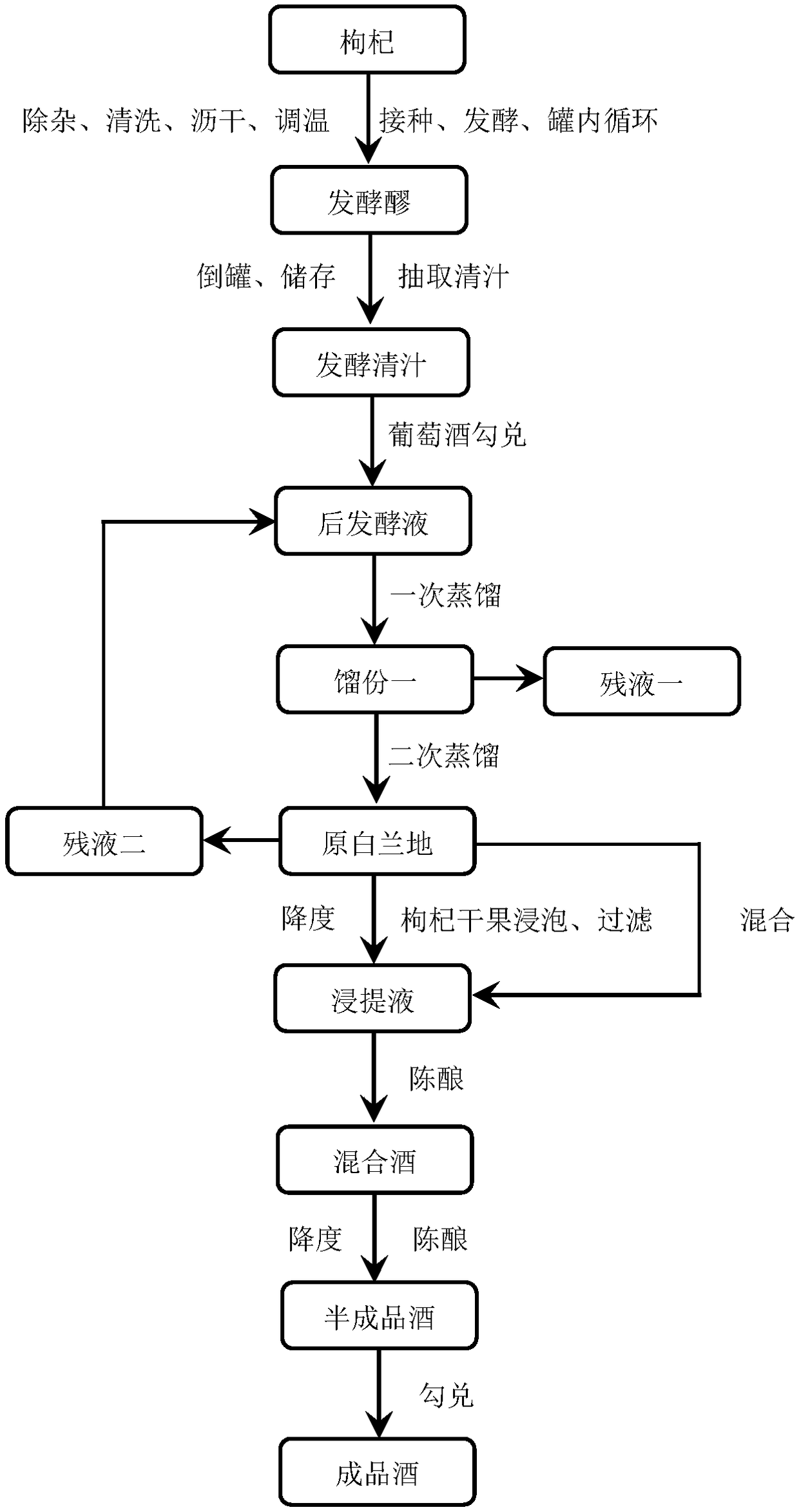

Method used

Image

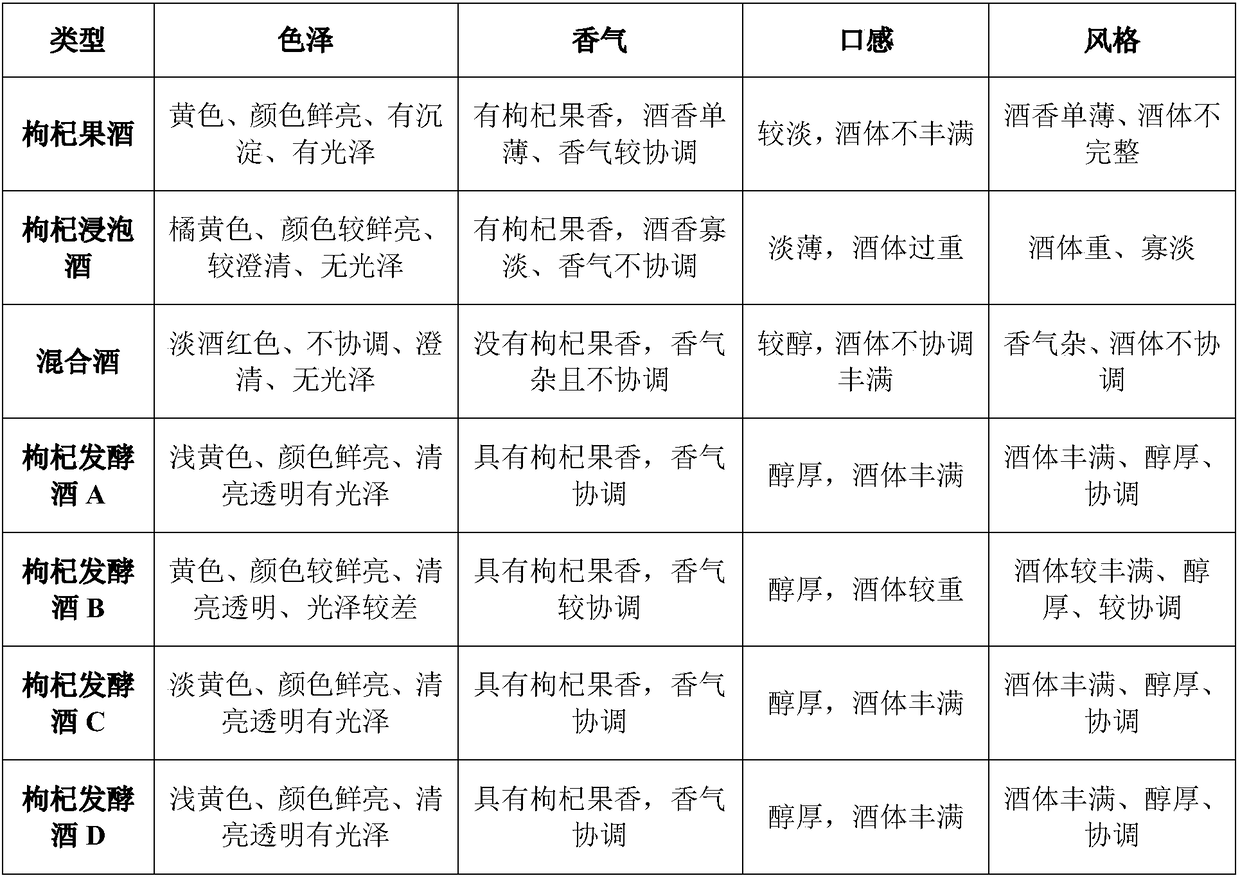

Examples

Embodiment 1

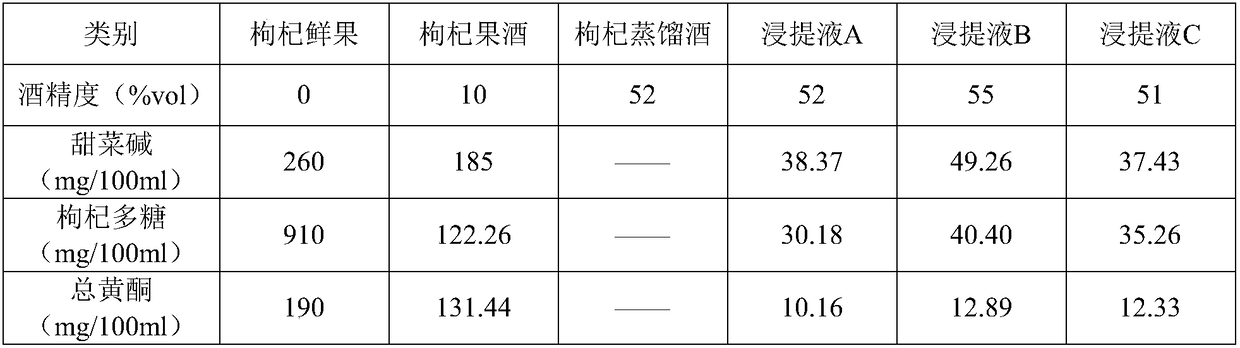

[0058] Preparation of wolfberry brandy and preparation of extract:

[0059] Main fermentation: remove diseased fruit, rotten fruit, broken fruit, leaves and stalks of wolfberry fresh fruit, wash and drain the water, refrigerate at 2°C for 10 hours, squeeze the juice, heat the juice to 18°C, add BV818 yeast, add 0.3g / L fermentation after 45 hours Auxiliary FN502, top temperature ≤ 22 ℃ fermentation until residual sugar 3g / L to terminate the main fermentation. During the main fermentation process, the fermented mash circulates; open cycle once on the 1st day of fermentation, the circulation volume is 1 / 4 of the fermented mash; open cycle once on the 2nd day of fermentation, the circulation volume is 1 / 2 of the fermented mash; 1 / 4 of the fermented mash; from the 4th to 5th day of fermentation, closed cycle once a day, 1 / 2 of the fermented mash; from the 6th day to the end of fermentation, closed cycle once a day, The circulation volume is 1 / 4 of the fermented mash.

[0060] Pos...

Embodiment 2

[0064] Preparation of wolfberry brandy and preparation of extract:

[0065] Main fermentation: Remove diseased fruit, rotten fruit, broken fruit, leaves and stalks of wolfberry fresh fruit, wash and drain, refrigerate at 10°C for 2 hours, squeeze the juice, heat the juice to 20°C, add BV818 yeast, add 0.4g / L fermentation after 52 hours Auxiliary FN502, top temperature ≤ 22 ℃ fermentation to 2.8g / L residual sugar to stop the main fermentation. During the main fermentation process, the fermented mash circulates; open cycle once on the 1st day of fermentation, the circulation volume is 1 / 4 of the fermented mash; open cycle once on the 2nd day of fermentation, the circulation volume is 1 / 2 of the fermented mash; 1 / 4 of the fermented mash; from the 4th to 5th day of fermentation, closed cycle once a day, 1 / 2 of the fermented mash; from the 6th day to the end of fermentation, closed cycle once a day, The circulation volume is 1 / 4 of the fermented mash.

[0066] Post-fermentation: ...

Embodiment 3

[0070] Preparation of wolfberry brandy and preparation of extract:

[0071] Main fermentation: remove diseased fruit, rotten fruit, broken fruit, leaves and stalks of wolfberry fresh fruit, wash and drain the water, refrigerate at 6°C for 4 hours, squeeze the juice, heat the juice to 19°C, add BV818 yeast, add 0.35g / L fermentation after 48h Auxiliary FN502, top temperature ≤ 22 ℃ fermentation until residual sugar 3g / L to terminate the main fermentation. During the main fermentation process, the fermented mash circulates; open cycle once on the 1st day of fermentation, the circulation volume is 1 / 4 of the fermented mash; open cycle once on the 2nd day of fermentation, the circulation volume is 1 / 2 of the fermented mash; 1 / 4 of the fermented mash; from the 4th to 5th day of fermentation, closed cycle once a day, 1 / 2 of the fermented mash; from the 6th day to the end of fermentation, closed cycle once a day, The circulation volume is 1 / 4 of the fermented mash.

[0072] Post-fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com