Vacuum induction smelting process temperature real-time measurement, control and calibration system and method

A technology of vacuum induction melting and calibration system, applied in crucible furnaces, furnaces, charging processing types, etc., can solve the problems of temperature measurement deviation, temperature measurement deviation, pollution, etc., to improve production efficiency, accurate temperature values, and reduce labor the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

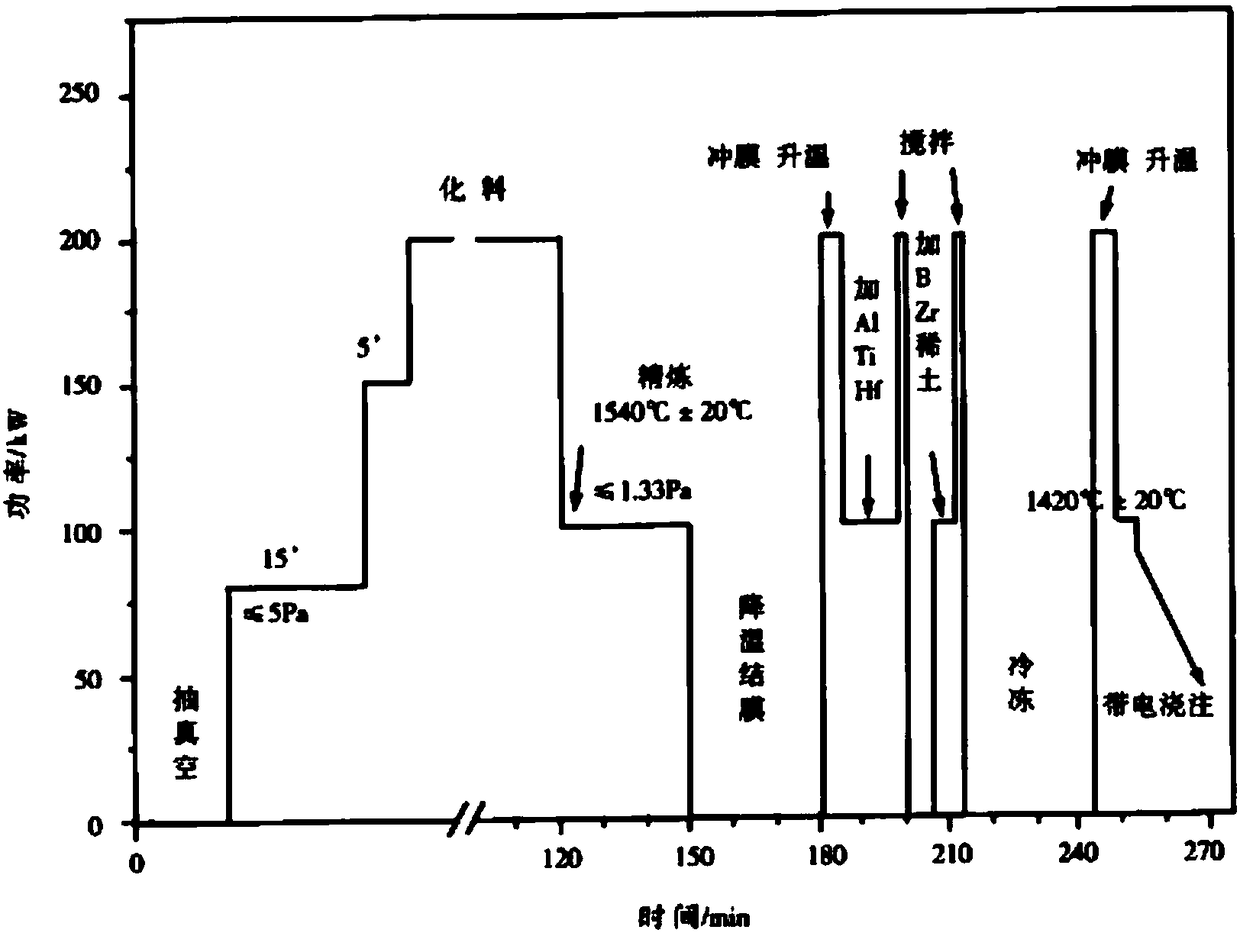

[0061] 7.5 kg of nickel-based superalloy was melted using the above-mentioned temperature real-time measurement, control and calibration system.

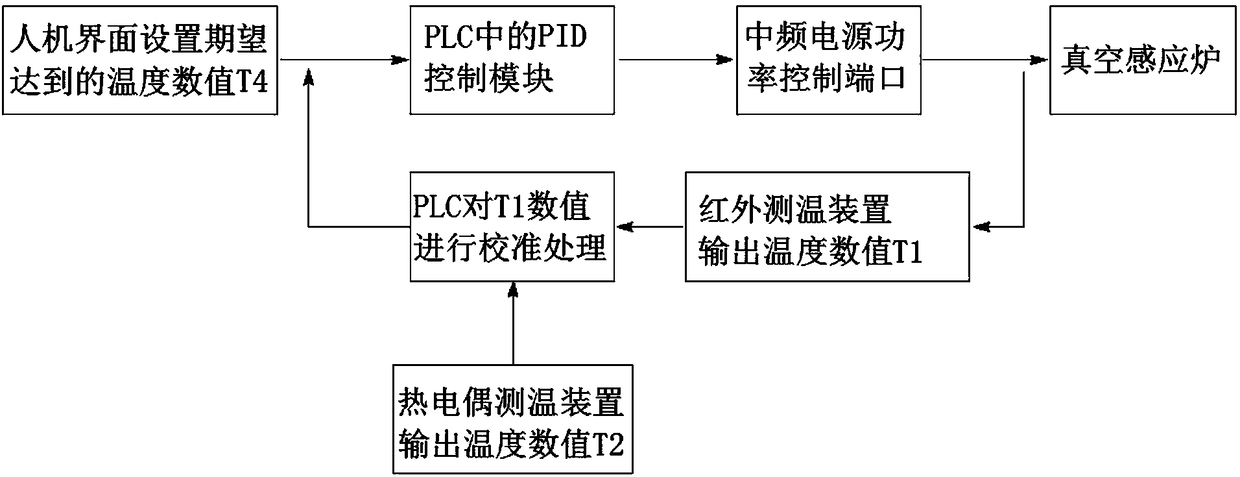

[0062] The vacuum induction furnace automatic temperature control system includes an infrared temperature measurement device, an infrared temperature signal transmission and output device, a programmable logic controller PLC, a man-machine interface for inputting operating parameters, and an intermediate frequency power supply control port. The program logic controller PLC adopts Siemens S7-1500PLC, the CPU is 1511C-1PN, and the model of the man-machine interface is Siemens KTP700basic-1PN.

[0063] Among them, the first input signal port AI0 port of the PLC is connected to the infrared temperature signal transmission output device, the output signal port AQ0 port of the PLC is connected to the power control port of the intermediate frequency power supply, and the programmable logic controller PLC and the man-machine interface are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com