Method for rapidly producing surface enhanced Raman active substrate

A surface-enhanced Raman and active substrate technology, applied in the field of analytical chemistry and nanometers, can solve the problems of high cost, cumbersome operation, and long time consumption, and achieve the effect of rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

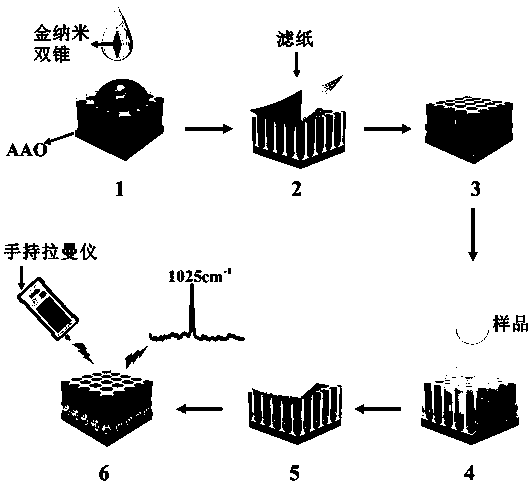

[0031] Example 1: Construction of Au NBPS-AAO surface-enhanced Raman substrate.

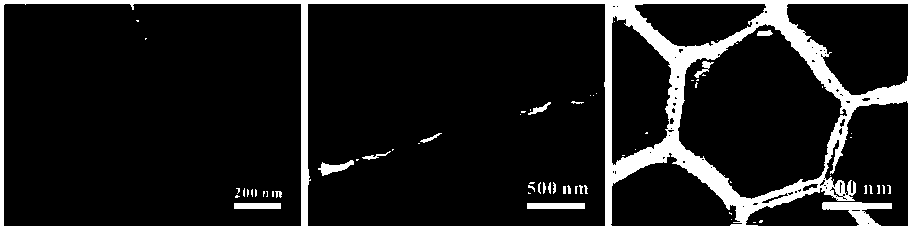

[0032] First use a size of 3.0 × 3.0 mm 2 The left and right porous anodized aluminum (pore diameter 300 nm, pore spacing 450 nm, pore depth 5 μm) was used as a template, and 10 μL of 1.2 × 10 −7 The gold nanobiconic solution of M was added dropwise on the surface of the AAO template, followed by a 2.0 × 2.0 cm 2 The filter paper absorbs the excess gold nanobicone solution on the surface of the AAO template. At this time, most of the gold nanobicone solution in the channel will remain inside. After 10 s of natural drying, the gold nanobicone will remain in each nanopore In the channel, the Au NBPs-AAO surface-enhanced Raman substrate was obtained immediately. Related operating principles such as figure 1 As shown, the Au NBPs-AAO surface-enhanced Raman substrate is characterized as figure 2 shown.

Embodiment 2

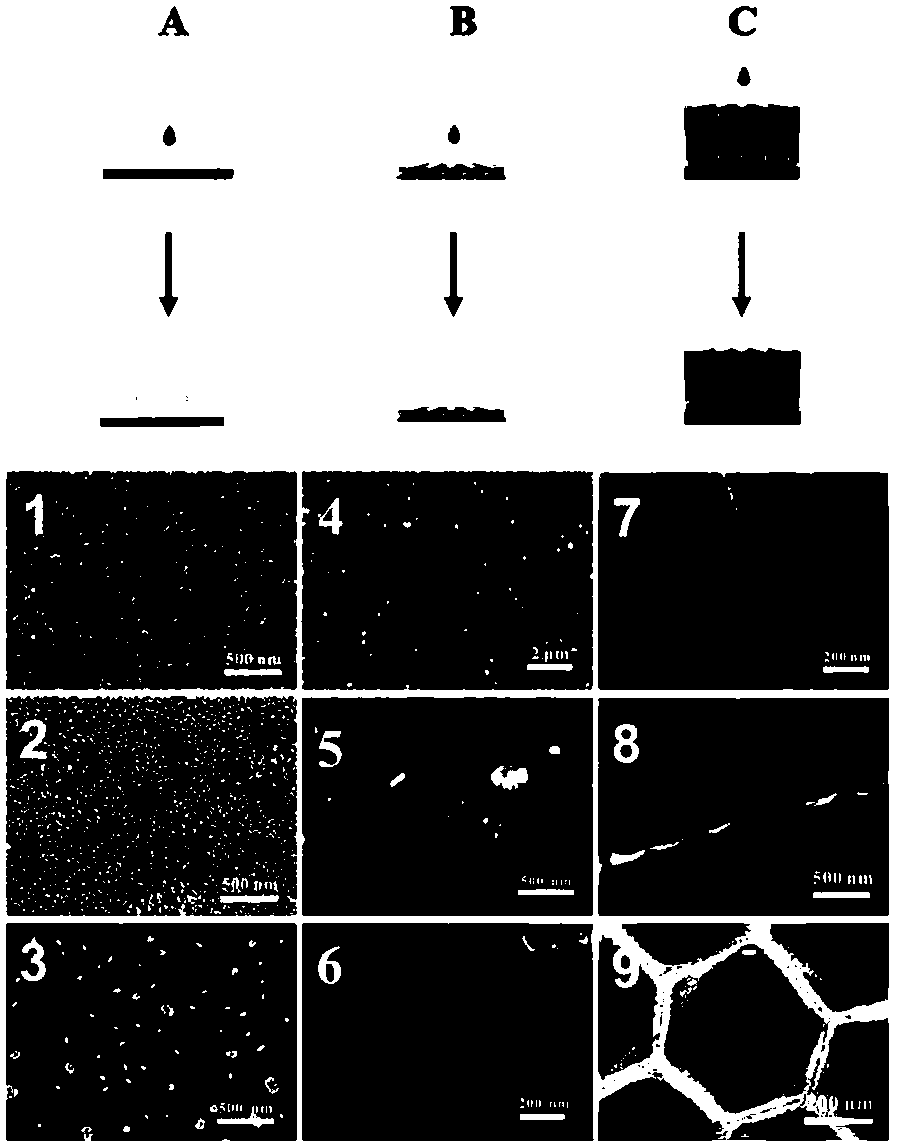

[0033] Example 2: Comparison of surface-enhanced Raman substrates prepared by different templates.

[0034] On the surface of the silicon wafer, the surface of porous anodized aluminum oxide Ⅰ (pore diameter 400 nm, pore spacing 450 nm, pore depth 100 nm), porous anodic aluminum oxide Ⅱ surface (pore diameter 300 nm, pore spacing 450 nm, pore depth 5 μm) was added dropwise 10 μL 1.2 × 10 −7 M gold nanobipyramidal solution, followed by a solution with a size of 2.0 × 2.0 cm 2 filter paper, absorb the excess gold nano-bicone solution on the surface of three different templates, and after standing for 10 seconds, three different surface-enhanced Raman active substrates can be obtained. 10 μL of rhodamine 6 G solution was added dropwise on the surface of the above three different surface-enhanced Raman active substrates, and then a 2.0 × 2.0 cm 2 The filter paper was used to absorb the excess rhodamine 6 G solution on the surface of three different surface-enhanced Raman active...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

| Hole spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com