Method for visual detection of defects of light guide plate of two-side light-incoming type

A technology of visual inspection and light guide plate, applied in the field of computer vision, can solve problems such as difficult implementation of embedded systems, poor working environment, and poor eyesight of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

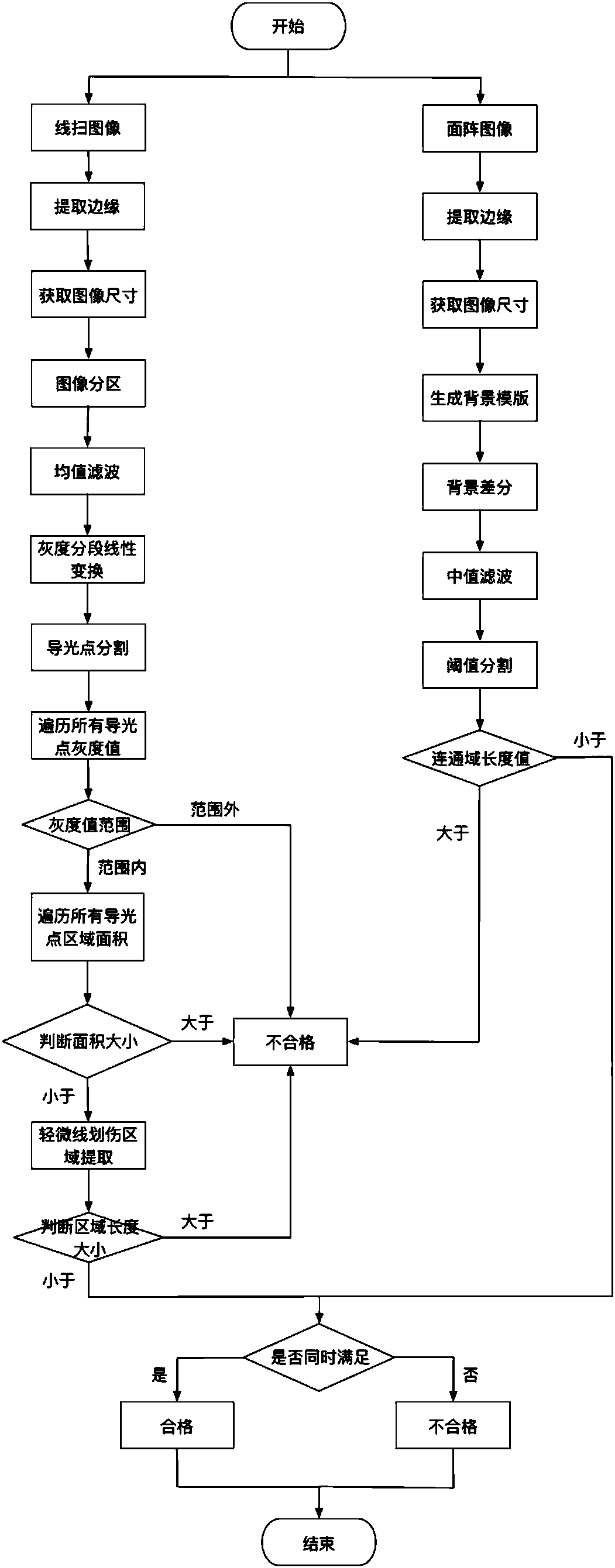

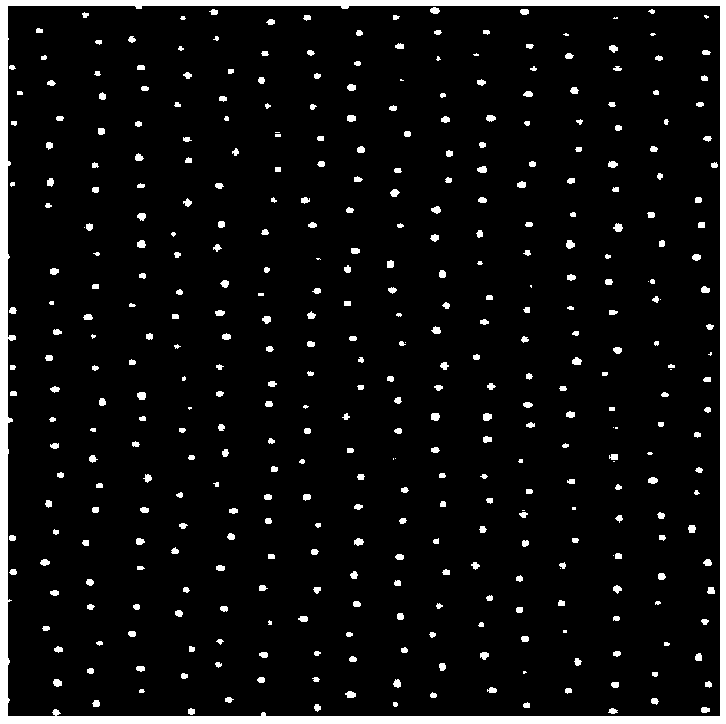

[0082] Embodiment 1. A method for visual detection of defects in a double-sided light incident type light guide plate, such as Figure 1-15 As shown, the present invention first builds a binocular inspection platform. The line scan camera is responsible for inspecting subtle defects such as scratches, crushes, bright and dark spots, and the area frame camera is responsible for detecting whether there is any shadow problem on the light guide plate after being illuminated. Secondly, for the image of the light guide plate with defects, identify the type of defect, calculate the size of the defect area, and judge whether it is qualified according to the technical requirements of different defects of the light guide plate. Finally, build an experimental platform and develop a defect detection system, and improve the accuracy, real-time and robustness of the detection system through experiments.

[0083] The specific solution is as follows:

[0084] Carry out step S1 and step 1 sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com