Image sensor and formation method of the same

An image sensor, dielectric layer technology, applied in the direction of electric solid device, semiconductor device, electrical components, etc., can solve the problems of high production cost, incident light loss, complex process, etc., to reduce process complexity, improve protection, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

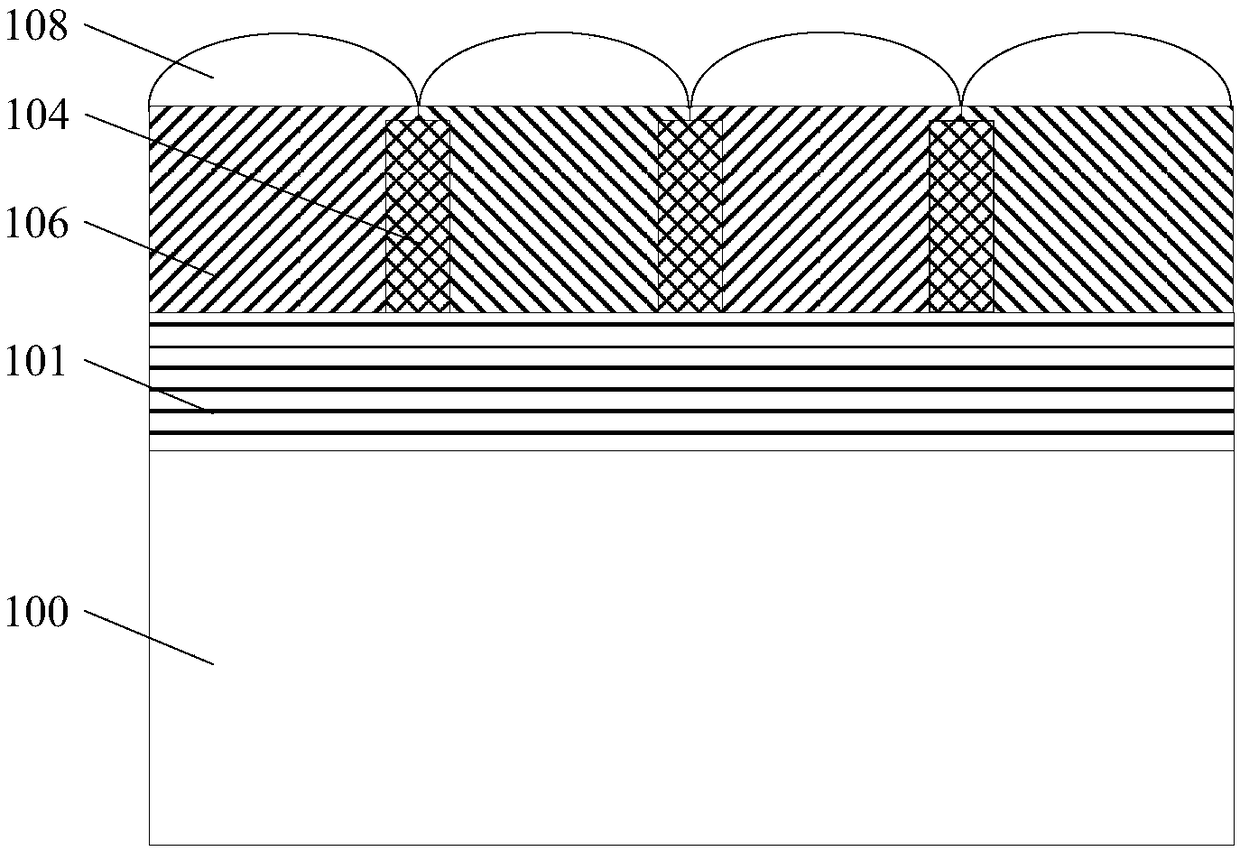

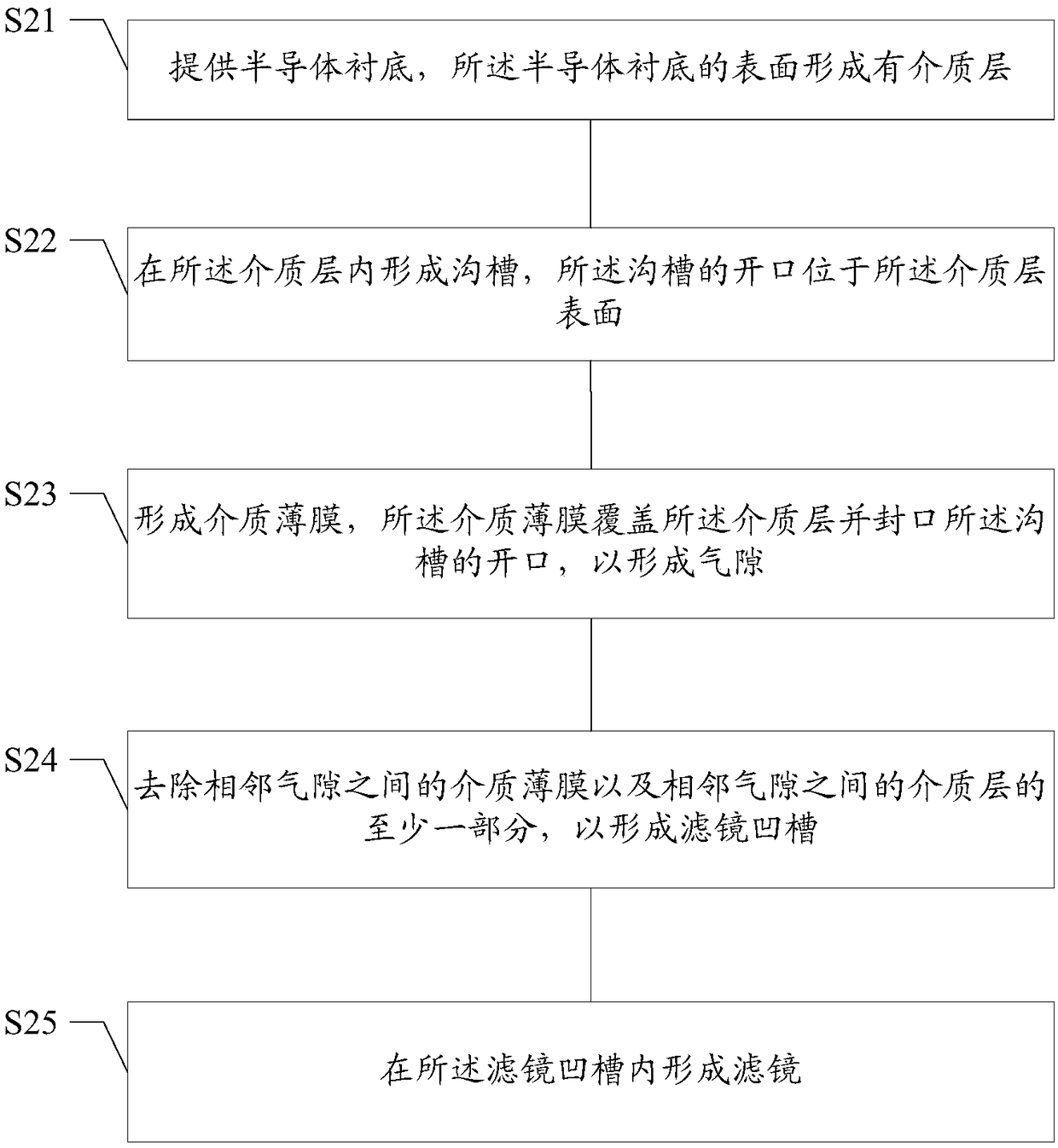

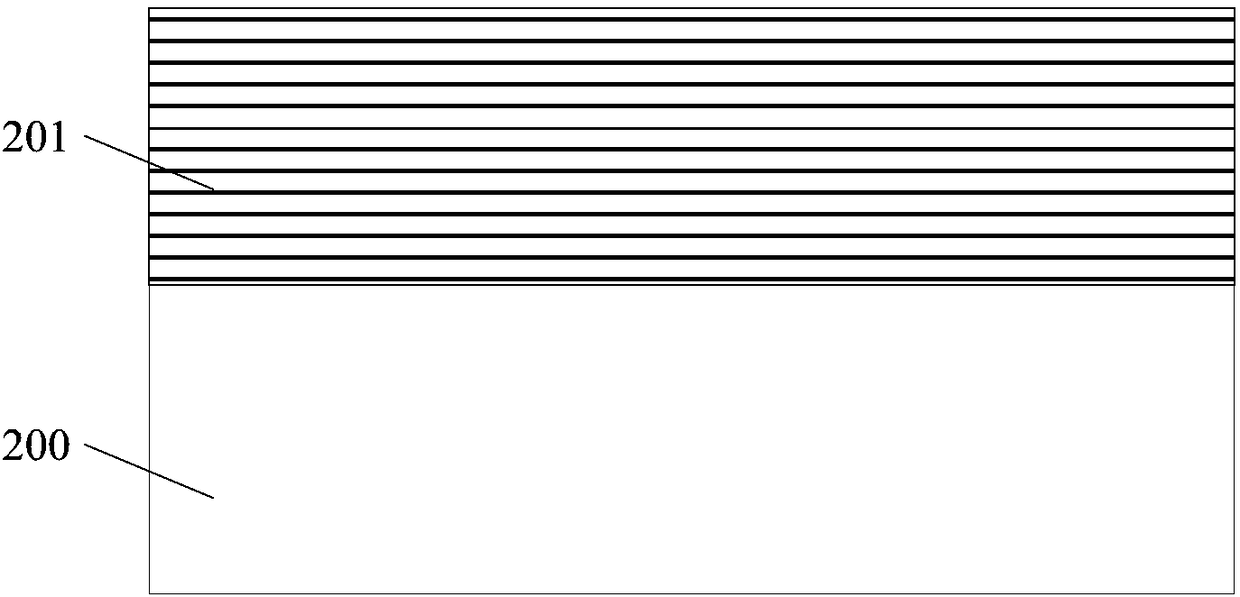

[0027] In the image sensor, after the lens structure captures the incident light, it is filtered by a filter matrix to remove irrelevant light and form monochromatic light. The incident photons reach the semiconductor substrate and are absorbed by the pixel device to generate photogenerated carriers. Since optical crosstalk easily occurs before the light reaches the silicon substrate and affects the imaging effect, it is necessary to form a metal grid on the surface of the semiconductor substrate to isolate the incident light. However, in the prior art, the process of forming the metal grid is relatively complicated, resulting in high production cost and easy formation of metal pollution. The metal grid also causes loss of incident light and reduces the photosensitivity of the image sensor.

[0028] The inventors of the present invention have found through research that when light is injected into the gas from a dielectric material (such as silicon oxide) and the incident angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com