Optical cabin environment monitoring device for high-power solid laser and control method thereof

A solid-state laser and environmental monitoring technology, which is applied in the direction of lasers, measuring devices, laser components, etc., can solve the problems of lack of in-depth research on the comprehensive reliability of software and hardware of measurement and control systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

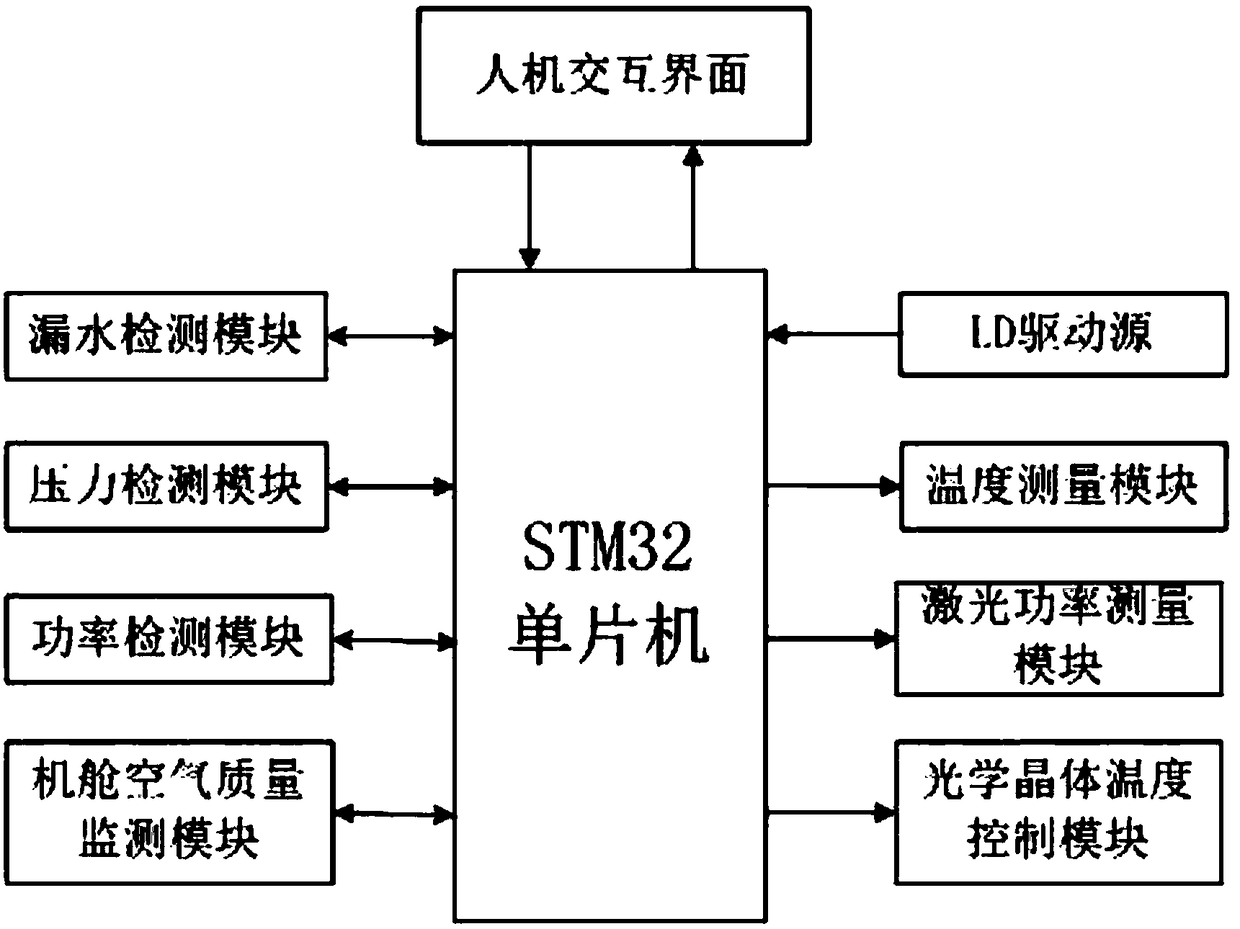

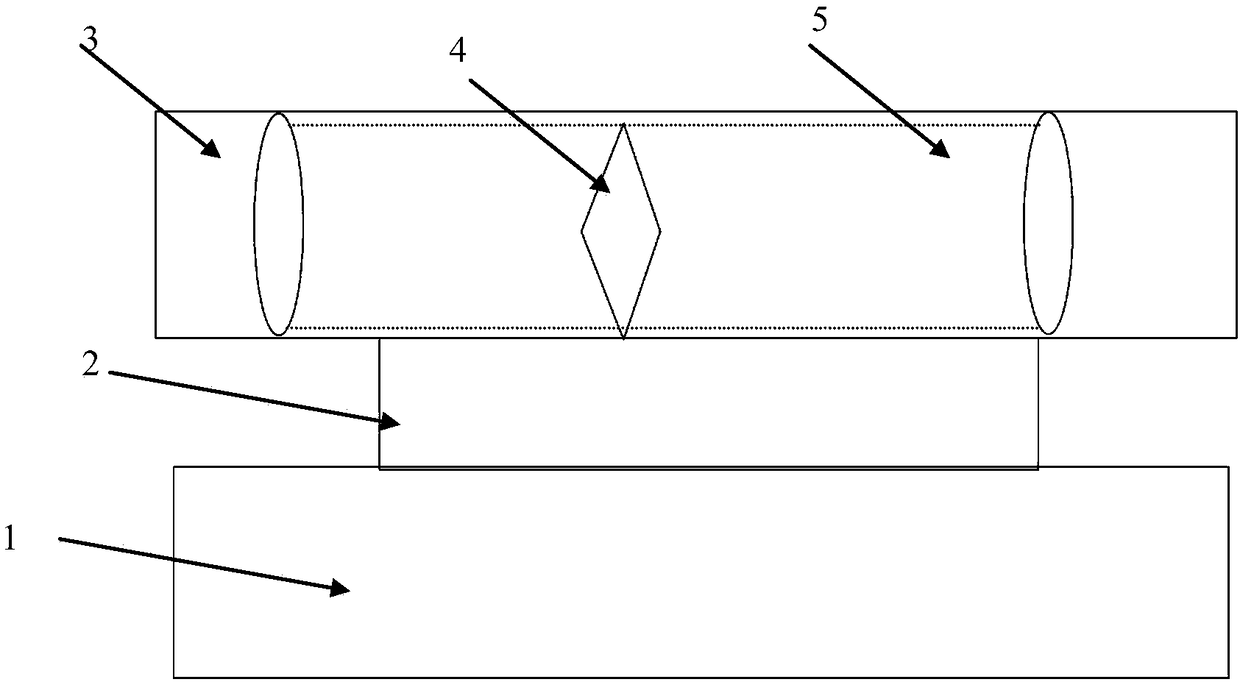

Embodiment 1

[0036] An optical cabin environment monitoring device for a high-power solid-state laser in this embodiment includes a cooling water circulation unit, and an optical crystal temperature control module includes a base 1 fixedly arranged in the optical cabin and circulating cooling water therein, for Install and fix the heat conduction carrier 3 of the optical crystal 5, the first temperature sensor 4 arranged in the heat conduction carrier, and the semiconductor refrigeration unit 2 arranged between the heat conduction carrier and the base; the cabin air quality monitoring module, comprising The temperature and humidity sensor arranged in the optical cabin; the controller, the controller is connected to the first sensor, the semiconductor refrigeration unit and the temperature and humidity sensor in communication, and at the same time, for the convenience of information output and parameter setting, It also includes a human-computer interaction screen connected with the single-c...

Embodiment 2

[0043] Further, the optical engine room environment monitoring device of the present invention also includes a water leakage detection unit, which includes a water level sensor arranged at a recessed position in the optical engine room and correspondingly arranged at the inlet and outlet of the cooling water pipeline of the cooling water circulation unit. sensor and water outlet pressure sensor, the water level sensor, water inlet pressure sensor and water outlet pressure sensor are respectively connected to the controller in communication, wherein, preferably, in order to improve assembly and installation accuracy, the water inlet pressure sensor and the water outlet pressure sensor The outlet water pressure sensors respectively include a pressure sensing unit, which is formed with an armored screw for positioning the hollow cavity of the pressure sensing unit, and the armored screw is threadedly connected with the cooling water pipeline.

[0044] The cooling water delivery pi...

Embodiment 3

[0047] Further, in order to improve the overall monitoring performance, it also includes an optical fiber temperature monitoring module, which is a second temperature sensor arranged on the optical fiber flange, and the second temperature sensor includes a temperature sensing unit, which is formed to position the The armored screw of the hollow cavity of the temperature sensing unit is threadedly connected with the optical fiber flange seat.

[0048] The second temperature sensor of the present invention, that is, the optical fiber temperature sensor and the temperature sensor used in the optical temperature control module have the same model and packaging method, are all grade A platinum resistors and are packaged with armored screws. The optical fiber temperature sensor is connected with the positioning screw hole on the optical fiber flange through the armored screw shell to complete the fixing of the temperature sensor. Since the optical fiber is placed close to the optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com