Ex-situ soil washing solid-liquid separation device and process

A technology of soil washing and solid-liquid separation, which is applied in the direction of sedimentation separation, separation method, feeding/discharging device of settling tank, etc., to achieve the effects of improving processing efficiency, low pore moisture content, and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

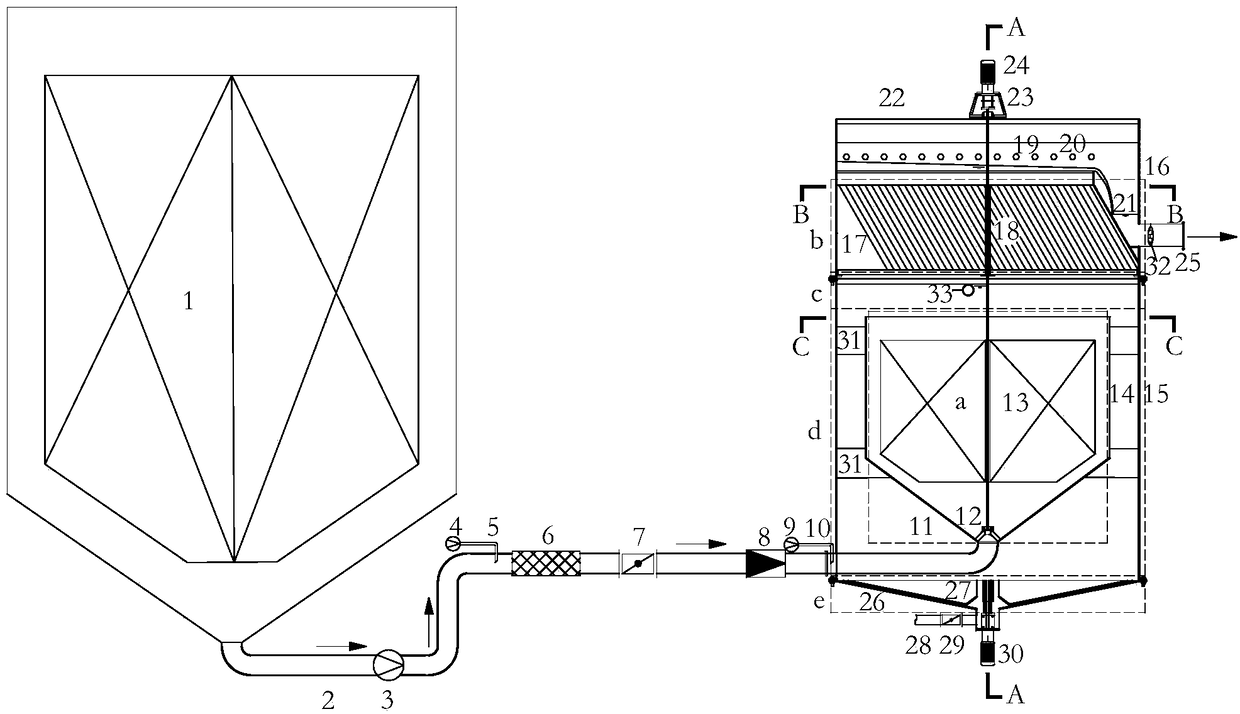

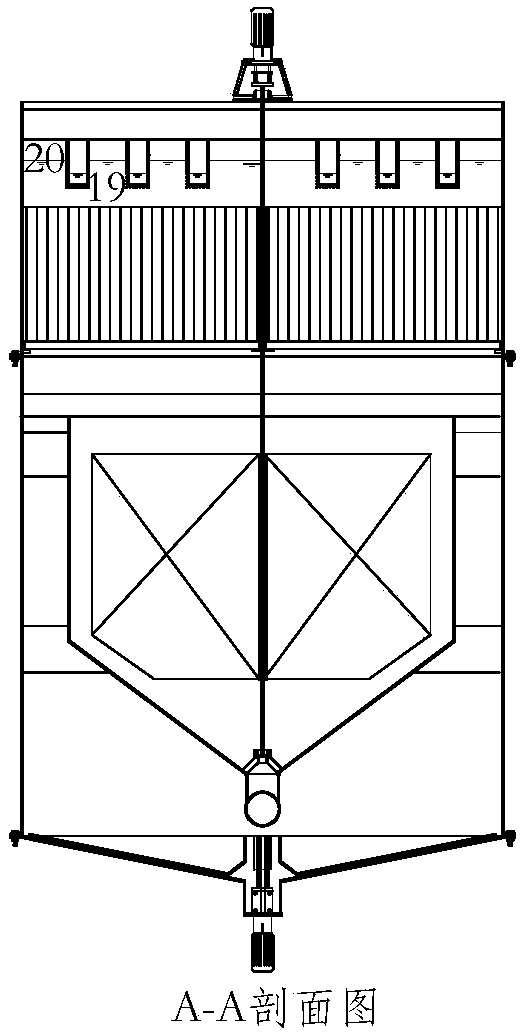

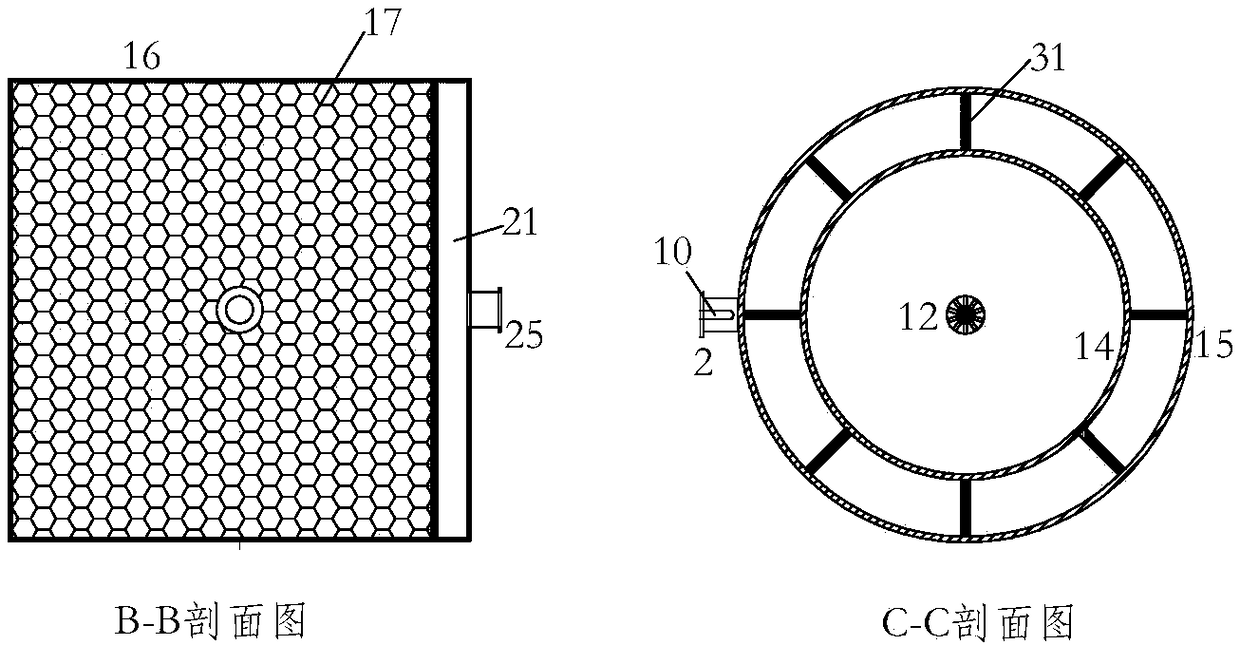

[0029] refer to figure 1, the present invention includes main equipment, auxiliary pipelines and valve systems, and a measurement and control system. The main equipment is a high-efficiency solid-liquid separator, and the peripheral structure is composed of an inner cylinder 14, an outer cylinder 15, an equipment upper body 16, a top cover 22, and bottom plates 11 and 26 of the inner and outer cylinders.

[0030] refer to figure 1 , to describe the process flow.

[0031] The soil is stirred and washed by the eluent in the rinsing tank 1 to form a mixed solution. After the mixed solution is pressurized by the lifting pump 3, it is fed from the water inlet pipe 2 through the flocculant dosing pipe 5, static mixer 6, electric control valve 7, The flow meter 8 and the coagulant dosing pipe 10 enter the loading flocculation area a of the high-efficiency solid-liquid separator. This area is composed of the inner cylinder 14, the inner cylinder bottom plate 11, the agitator 13 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com