Waterproof bamboo/wood modification method

A wood modification technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of substrate size deformation, water absorption increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

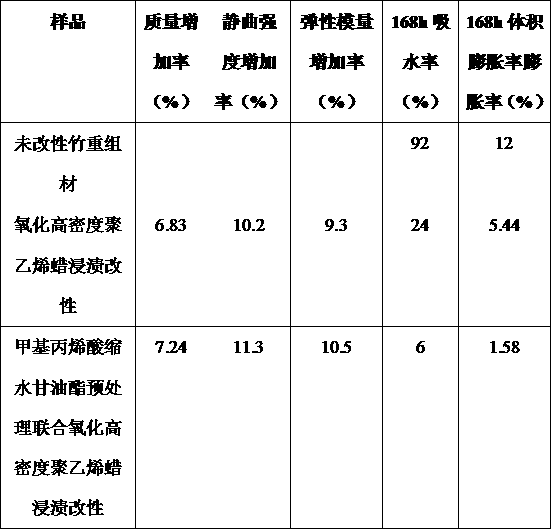

Embodiment 1

[0027] A modification method of waterproof bamboo / wood, comprising:

[0028] (1) Put the bamboo composite wood with the length, width and height of 800mm, 60mm and 12mm respectively into a drying oven and dry at 103°C for 24 hours;

[0029] (2) Dissolve glycidyl methacrylate in ethanol at a mass ratio of 0.5%, and add an initiator (azobisisobutyronitrile) to ethanol at a mass ratio of 0.1% of glycidyl methacrylate. After stirring, then sonicate for 10 minutes;

[0030] (3) Put the dried bamboo recombined wood into the solution prepared in step (2) and vacuum impregnate for 15 minutes at a vacuum pressure of 30 mbar;

[0031] (4) Take out the bamboo composite material impregnated in step (3), wipe off the excess solution on the surface, wrap it with aluminum foil, put it in an oven for 2 hours at 60°C, and then dry it at 80°C for 24 hours;

[0032] (5) Add oxidized high-density polyethylene wax emulsion in deionized water at a mass ratio of 0.2%, stir evenly for 10 Min, then ...

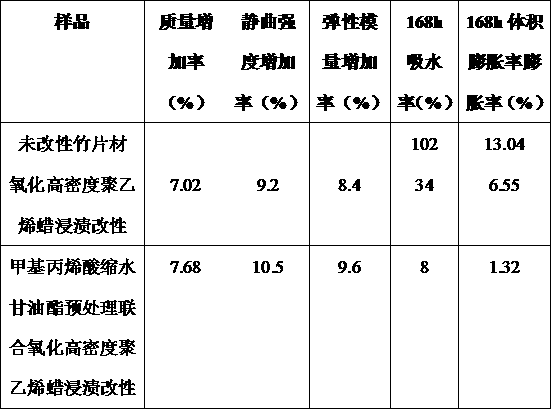

Embodiment 2

[0037] A modification method of waterproof bamboo / wood, comprising:

[0038] (1) Put the bamboo sheets whose length, width and height are 300mm, 20mm and 12mm respectively into a drying oven and dry at 103°C for 24 hours;

[0039] (2) Dissolve glycidyl methacrylate in ethanol at a mass ratio of 0.1%, and add an initiator (diacyl peroxide) into ethanol at a mass ratio of 0.3% of glycidyl methacrylate, and stir evenly , and then ultrasonic treatment for 10 minutes;

[0040] (3) Put the dried bamboo sheet into the solution prepared in step (2) and vacuum impregnate for 30 minutes, the vacuum pressure is 40mbar;

[0041] (4) Take out the bamboo sheet impregnated in step (3), wipe off the excess solution on the surface, wrap it with aluminum foil, put it in an oven for 2 hours at 60°C, and then dry it at 80°C for 24 hours;

[0042] (5) Add oxidized high-density polyethylene wax emulsion in deionized water at a mass ratio of 0.5%, stir evenly for 10 minutes, then put the bamboo re...

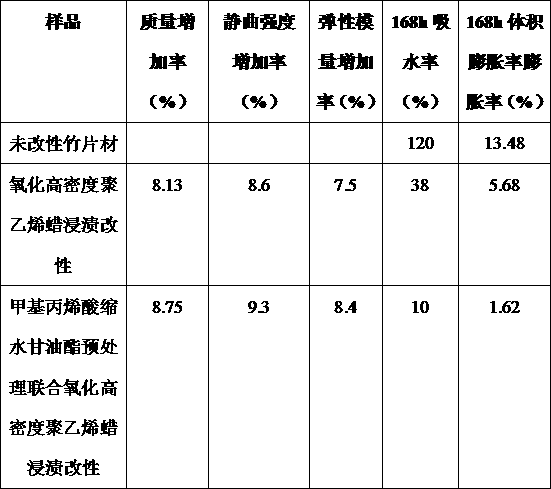

Embodiment 3

[0047] A modification method of waterproof bamboo / wood, comprising:

[0048] (1) Put the poplar wood with the length, width and height of 600mm, 50mm and 20mm respectively into the drying oven and dry at 103°C for 24 hours;

[0049] (2) Dissolve glycidyl methacrylate in ethanol at a mass ratio of 3%, and add an initiator (persulfate) to ethanol at a mass ratio of 0.2% of glycidyl methacrylate, and stir evenly. Sonicate for another 10 minutes;

[0050] (3) Put the dried wood into the solution prepared in step (2) and vacuum impregnate for 10 minutes, the vacuum pressure is 35mbar;

[0051] (4) Take out the wooden beam impregnated in step (3), wipe off the excess solution on the surface, wrap it with aluminum foil, put it in an oven for 2 hours at 60°C, and then dry it at 80°C for 24 hours;

[0052] (5) Add oxidized high-density polyethylene wax emulsion in deionized water at a mass ratio of 2%, stir evenly for 8 Min, then put the wood squares treated in step (4) into it for 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com