Bar material feeding device with hanging head

A technology for feeding devices and rods, which is applied in transportation and packaging, metal processing equipment, metal processing, etc., can solve the problems of reducing the detection accuracy of pressure sensors, low positioning accuracy, and low probability of material suction, and overcome the decline in positioning accuracy , High probability of inhalation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

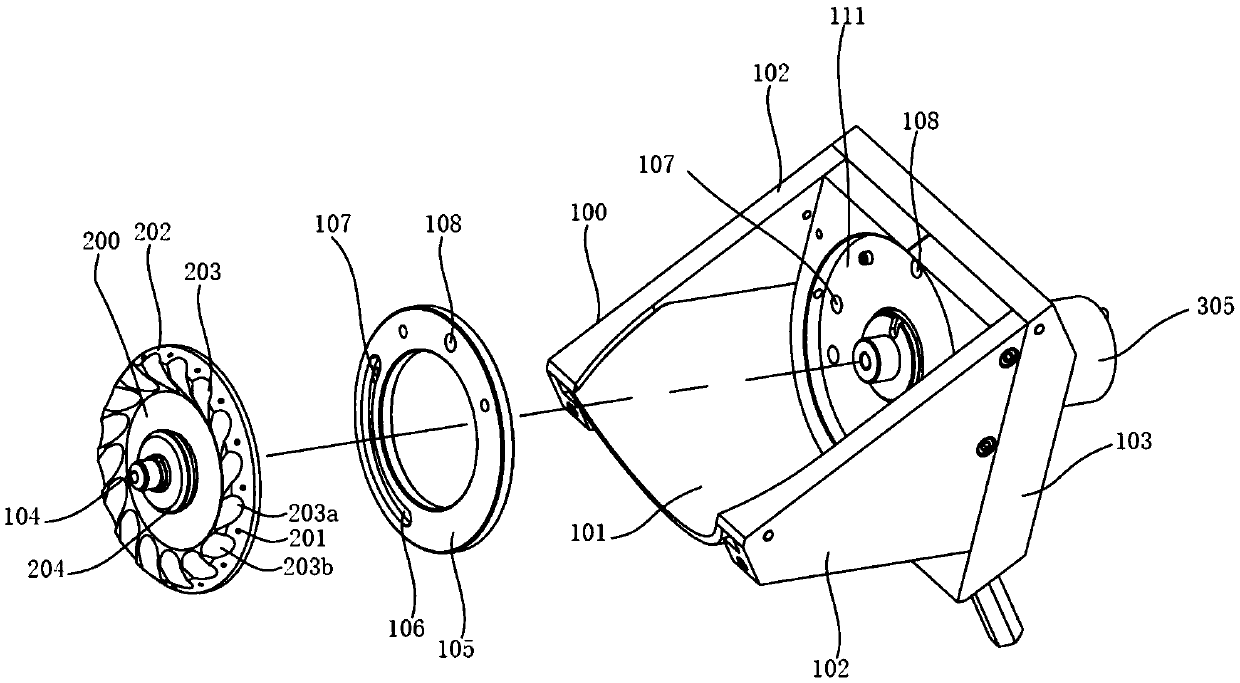

[0038] Such as Figures 1 to 8 As shown, the rod feeding device with suspension head includes a hopper 100 with an opening upward, a rotating shaft 104 vertically rotatably connected to the side wall of the hopper 100, a turntable 200 located in the hopper 100 and coaxially connected with the rotating shaft, and a The drive mechanism 300 that drives the shaft to rotate outside the hopper 100; the hopper 100 includes an arc panel 101, a side plate 102, and a mounting plate 103 with an arc-shaped bottom. An annular sealing ring 105, an annular groove 111 for fitting the annular sealing ring 105 is arranged on the mounting plate, and at least An arc groove 106, in the arc groove 106, is provided with several suction holes 107 through the annular sealing ring 105 and the mounting plate 103; There is a through confirmation suction hole 108; the outer peripheral surface of the turntable 200 is evenly distributed in the circumferential direction with a plurality of suction holes 201...

Embodiment 2

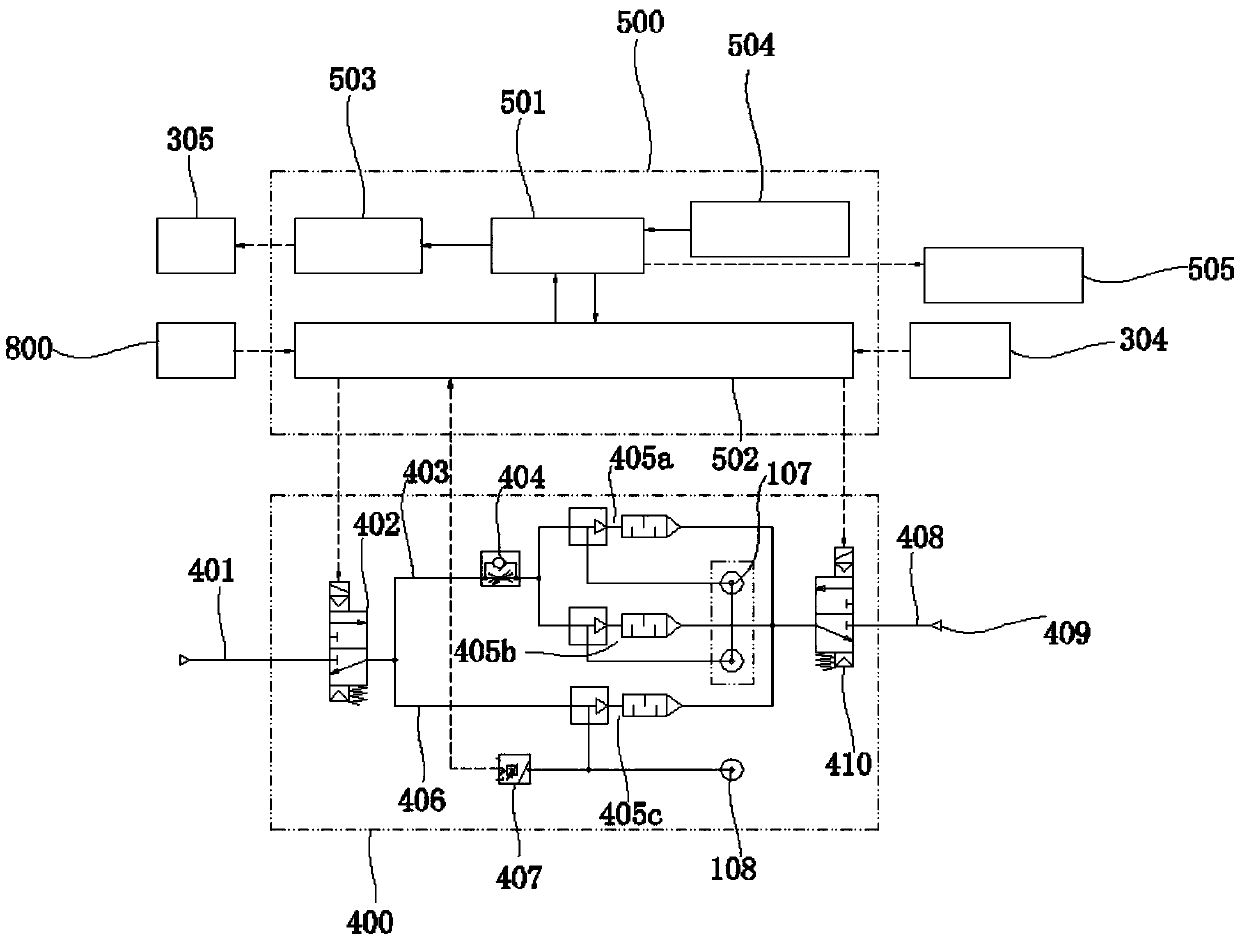

[0051] In Embodiment 1, after confirming that the position surface sensor 304 detects the position of the lever 303, the signal is sent to the control unit 500, and then the control unit gives the signal to the corresponding mechanism, such as the take-out mechanism 800 and the motor 305, and there are devices The reaction time is short, and the motor 305 cannot suddenly stop after detecting the position signal of the lever, so that the dial 302 and the sheave 301 may miss the best fitting position when the take-out mechanism operates. Embodiment 1 is suitable for low-speed drive feeding.

[0052] Embodiment 2 On the basis of Embodiment 1, a driving mechanism suitable for high-speed drive feeding is provided, which can respond quickly and adjust the relative positions of the dial, the dial lever and the sheave.

[0053] Such as Figure 9 As shown, the drive mechanism 300 includes a sheave 301, a dial 302, a lever 303, a motor 305, and a sensor 304b for confirming a position; ...

Embodiment 3

[0055] On the basis of Embodiment 1 or 2, Embodiment 3 provides an embodiment of a preferred material shifting mechanism.

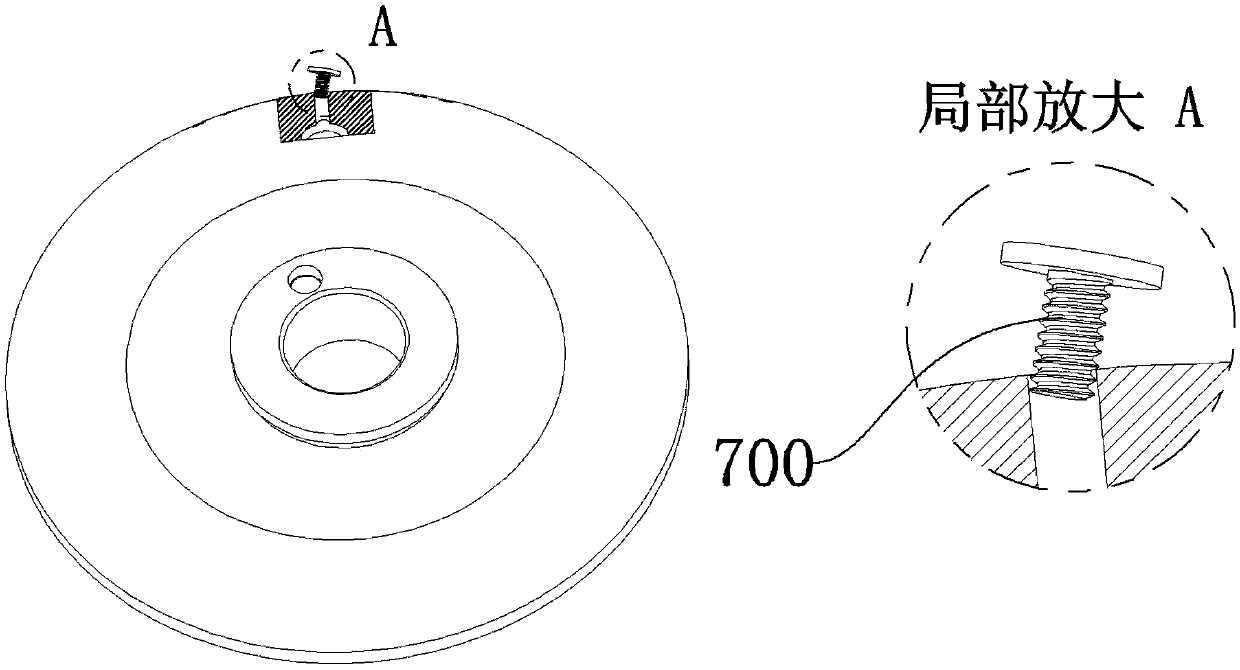

[0056]As shown in 10, an installation hole is provided on the installation plate 103 between the arc groove 106 inside the hopper 100 and the confirmation suction hole 108, and the dialing mechanism 600a is installed. The dialing mechanism 600a includes a mounting block 601a, a fixing screw 602a, a spring 603a, shifting lever shaft 604a and shifting claw 605a; the upper surface of the mounting block 601a is provided with a shifting rod shaft hole, and the shifting rod shaft is connected with the shifting claw with fixing screws, and the lower surface of the mounting block 601a is provided with a T-shaped groove, and a T-shaped groove A spring 603a and a lever shaft 604a are installed vertically inside.

[0057] Similarly, the mounting plate 103 on the outside of the hopper 100 is provided with a lever shaft hole and a T-shaped groove penetrating to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com