Sword bean sheller and sword bean shelling method

A technology of shelling machine and sword bean, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of unsuitable shelling of sword bean, hindering the industrialization development of deep processing of sword bean, and lack of hulling machine for sword bean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

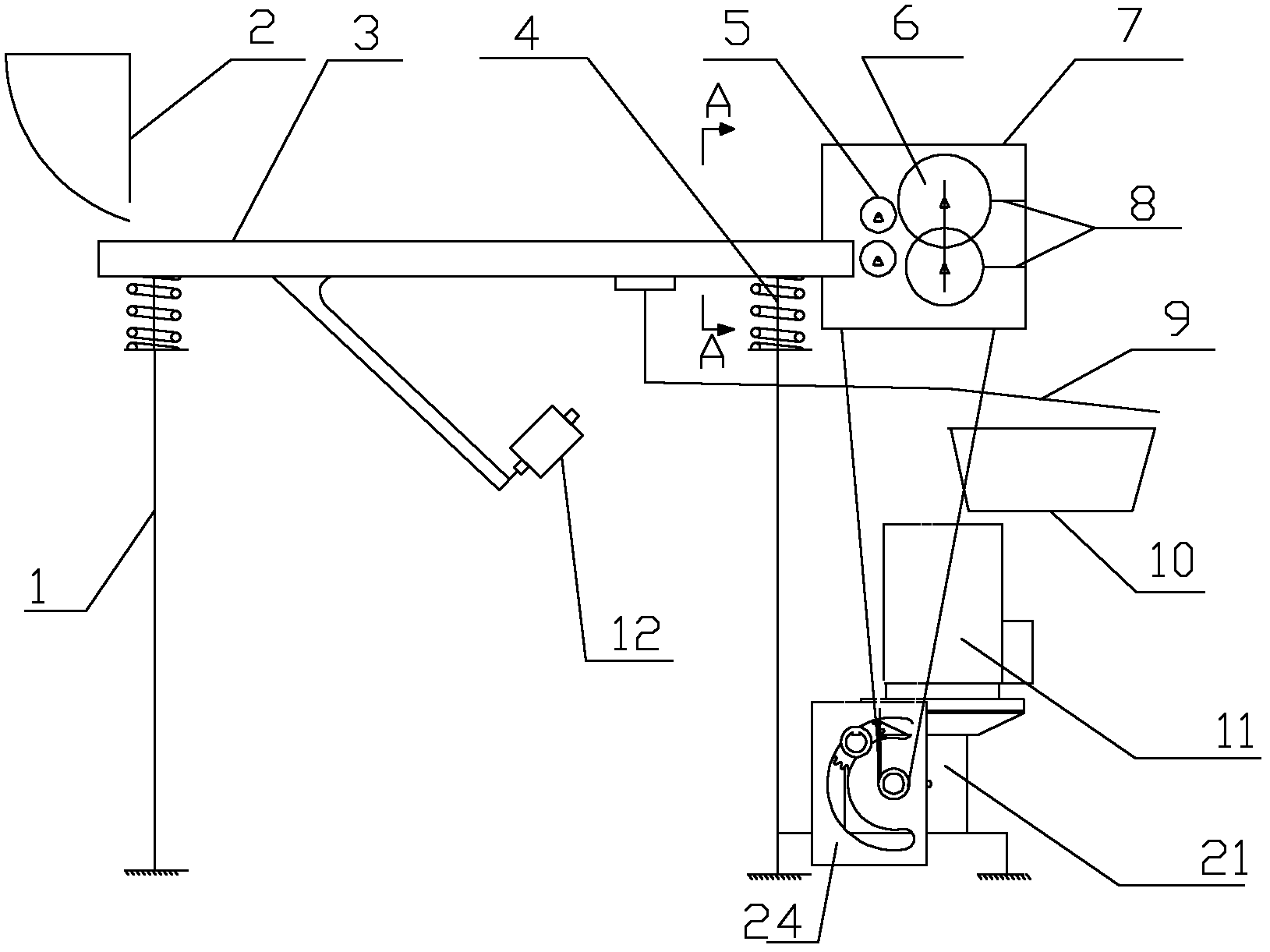

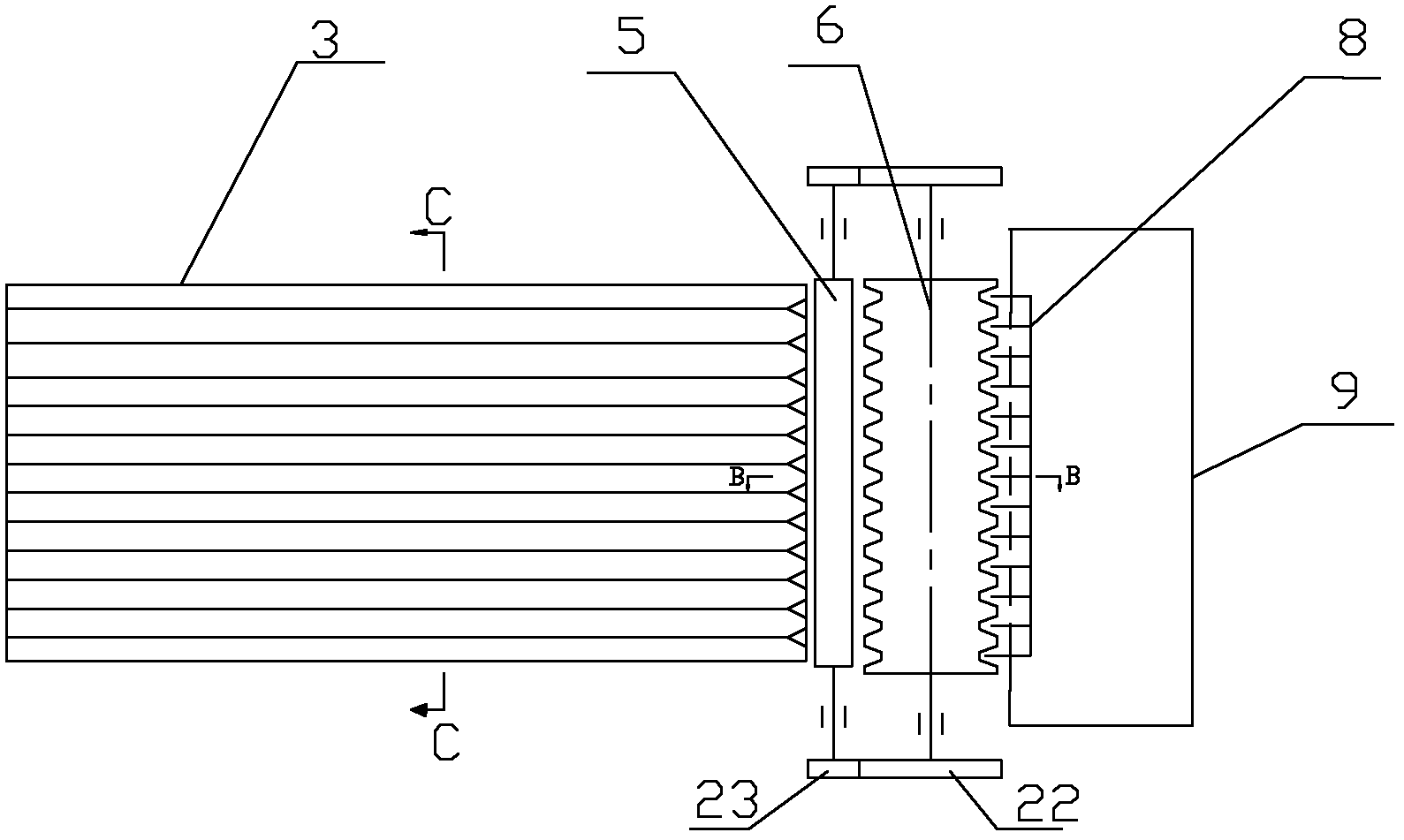

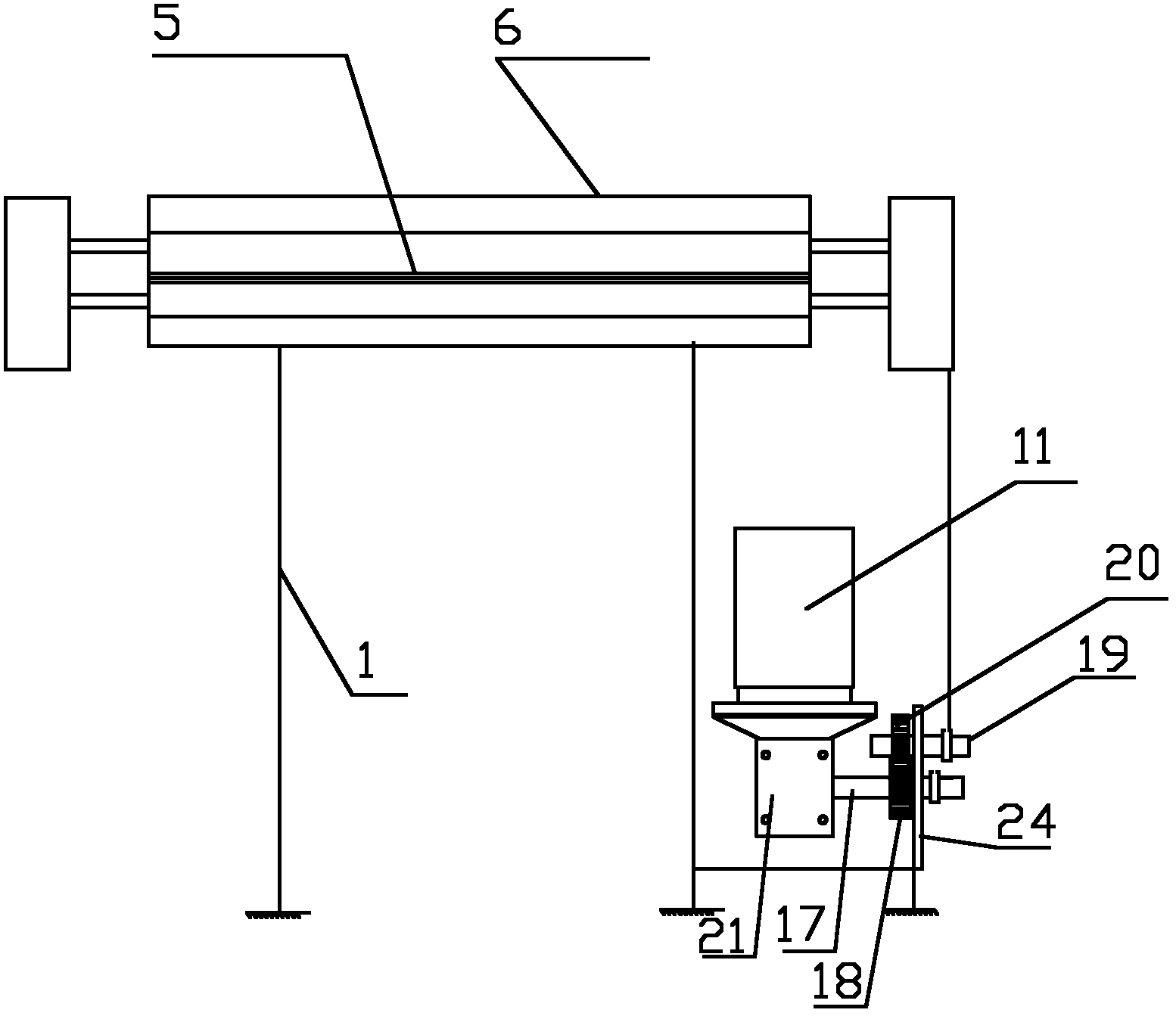

[0051] Figure 1 to Figure 11 Shows the specific structural schematic diagram of this embodiment, such as figure 1 As shown, the sword bean shelling machine includes a frame 1, a feed hopper 2, a vibrating bed 3, a vibrating drive mechanism, a pair of clamping rolls 5, a pair of shelling rolls 6, a roll bearing seat, a roll box 7, Transmission mechanism, main motor 11, cleaning comb 8, separation screen 9 and receiving box 10, vibrating bed 3 is fixed on the frame 1, the feed hopper 2 is fixed on the head end of vibrating bed 3, and the roll box The body 7 is fixed on the tail end of the vibrating bed 3, and the roll bearing seat is placed in the roll box 7; as figure 1 and image 3 As shown, the pair of clamping rolls 5 and the pair of shelling rolls 6 are sequentially connected to the roll bearing housings from left to right, and they are all connected to the transmission mechanism to form the shelling working mechanism together. The shell of the shelling working mechanism...

Embodiment 2

[0078] This embodiment has the same structural features as Embodiment 1 except for the following features: the center distance between the shelling roll pair and the clamping roll pair is 200 mm; the clamping driving roll and the clamping driven roll The size of the gap is 15mm; the size of the gap between the tooth crests of the husking driving roller and the tooth grooves of the husking driven roller is 3mm larger than the thickness of the processed sword bean kernels.

Embodiment 3

[0080] This embodiment has the same structural features as Embodiment 1 except for the following features: the center distance between the shelling roll pair and the clamping roll pair is 180 mm; The size of the gap is 12 mm; the gap between the tooth tops of the husking driving roller and the tooth grooves of the husking driven roller is 2.5 mm larger than the thickness of the processed sword bean kernels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com