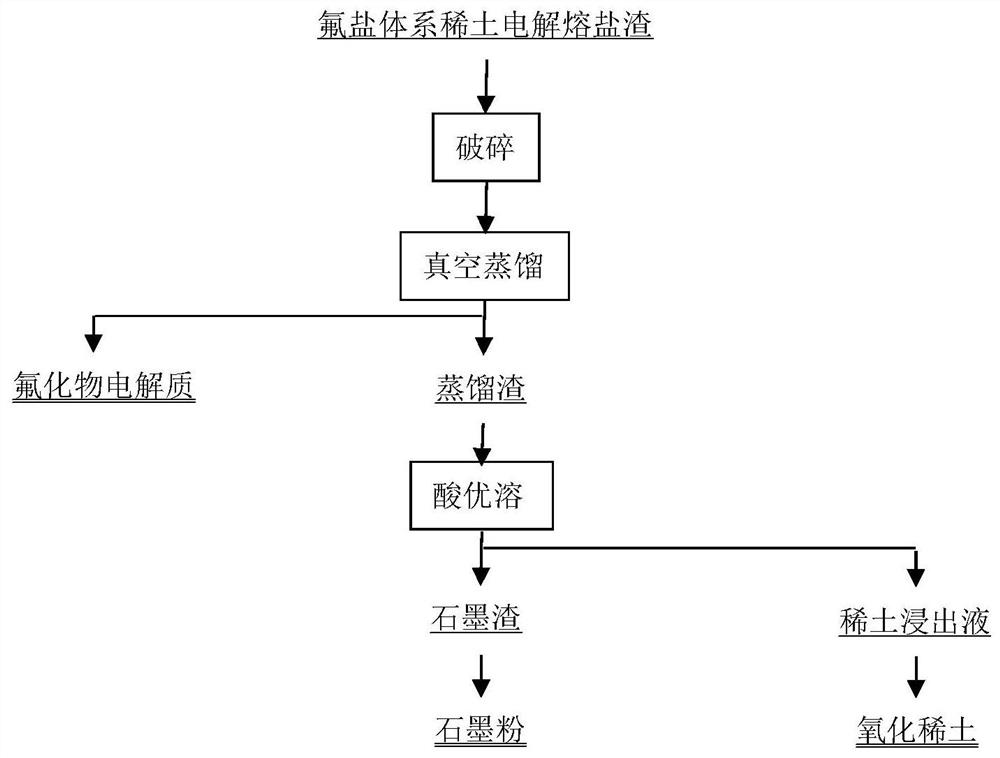

A method for separating and recovering electrolyte components from fluorine salt system rare earth electrolysis molten salt slag

A technology for separating electrolyte and slag, applied in the fields of metallurgy and environmental protection, can solve problems such as difficult and efficient comprehensive recycling, and achieve the effects of high comprehensive recovery value, simple operation, and avoidance of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

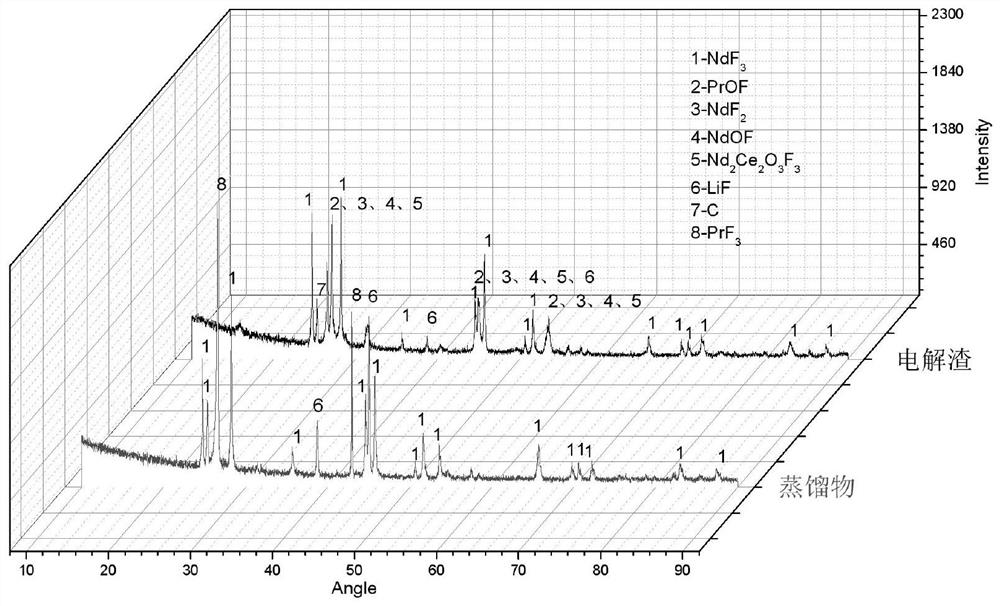

Method used

Image

Examples

Embodiment 1

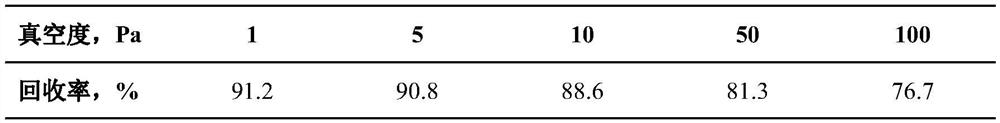

[0021] The rare earth electrolyte salt is placed in a vacuum distillation tank, and the particle size of 50 ° C in the vacuum distillation temperature is 50 megabytes, and the distillation time is 4 h. The effect of the inner vacuum on the recovery of fluoride electrolyte is. As shown in Table 1.

[0022] Table 1 Effect of vacuum degrees to fluoride electrolyte recovery rate

[0023]

Embodiment 2

[0025] The rare earth electrolyte salt was placed in a vacuum distillation tank, and the particle size of 5 Pa and the material particle size was 50 mesh and the distillation time was 4 h, and the effect of distillation temperature on the fluoride electrolyte recovery rate is investigated. Indicated.

[0026] Effect of Table 2 Distillation Temperature on Recovery of Fluoride Electrolyte

[0027]

Embodiment 3

[0029] The rare earth electrolyte salt was placed in a vacuum distillation tank, and the particle size of 50 ° C in the vacuum distillation was 50 megab, and the vacuum degree was 5Pa. The results of the distillation time on the restriction rate of fluoride electrolyte. 3 shown.

[0030] Effect of Table 3 Distillation Time on Recovery of Fluoride Electrolyte

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com