Domestic wastewater treatment method and treatment device based on gy-2 water treatment filler

A GY-2, domestic wastewater technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of unsuitable domestic sewage treatment, difficult to meet discharge standards, and high operating costs , to achieve good removal effect, efficient removal, and short construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A GY-2 water treatment filler, including main raw materials and auxiliary materials.

[0041] Wherein the preparation method of main body material is:

[0042] (1) Drying waste organic matter such as chaff and branches, and crushing to a particle size of 1.4-4mm to obtain waste organic matter powder, the moisture content of the waste organic matter powder is kept at about 50%.

[0043] (2) Compost waste organic matter powder with a heap height of 1.2m, and perform anaerobic fermentation for 15 days to obtain anaerobic fermentation products.

[0044] (3) Grinding carbonaceous raw materials such as cinder, coal ash, organic soil, and mineralized waste to a particle size of 0.42-30mm, the organic matter content of carbonaceous raw materials is less than 15%, and the specific gravity is controlled at 1.2-1.5g / cm 3 . The carbonaceous material is uniformly mixed into the anaerobic fermentation product treated in step (2), and the organic matter content in the main material ...

Embodiment 2

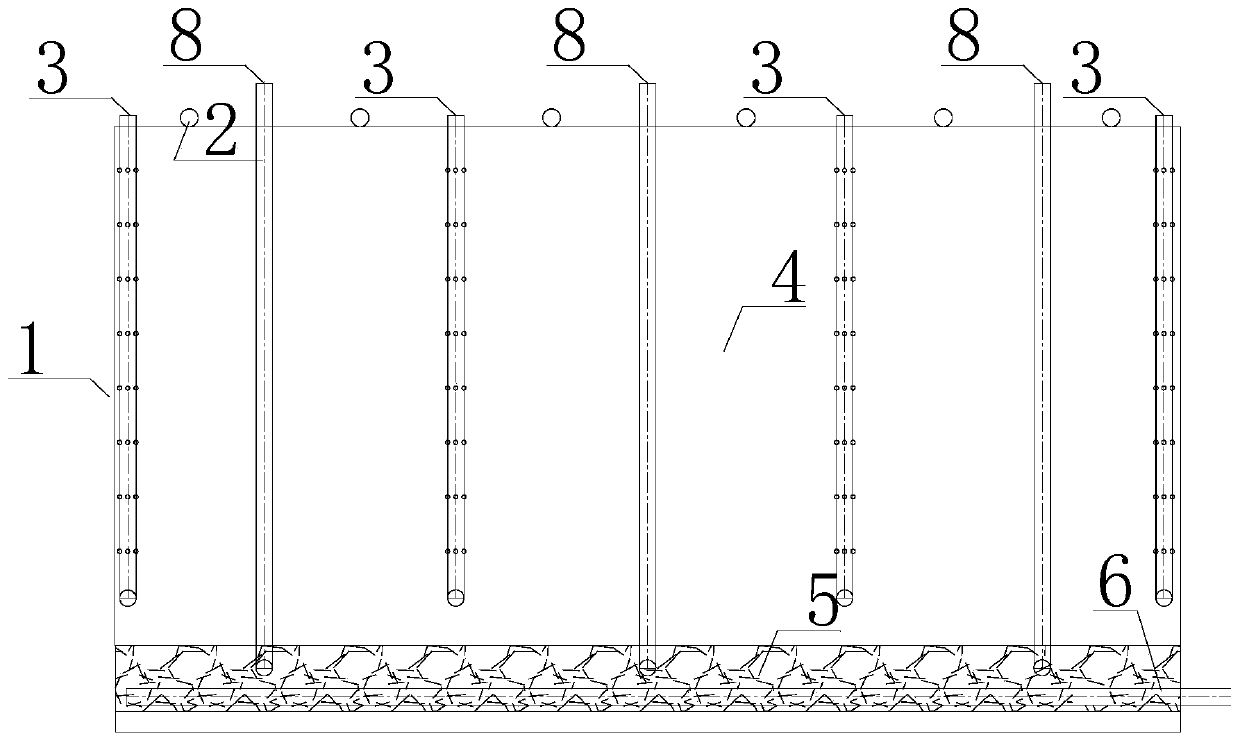

[0055] A treatment device for organic waste water, see figure 1 , including a reactor 1, a water distribution pipe 2, a plurality of mechanical ventilation pipes 3, a plurality of natural ventilation pipes 8, a filter bed 4 and a gravel layer 5.

[0056] The filter bed 4 is formed by filling the GY-1 type water treatment filler in the reactor 1, and the bottom of the filter bed 4 is provided with a gravel layer 5, and a plurality of natural ventilation pipes 8 and a plurality of mechanical ventilation pipes 3 are vertically inserted into the filter bed 4; The water distribution pipe 2 is arranged at the top of the reactor 1. Further, the area and thickness of the filter bed 4 are determined according to the daily water inflow, the area of the filter bed 4 is 8-10 times of the daily water inflow, the area of the filter bed 4 is 400-500m2, and the thickness of the filter bed 4 is determined to be 1.5m ~2m.

[0057] Further, the water distribution pipe 2 is arranged on the ...

Embodiment 3

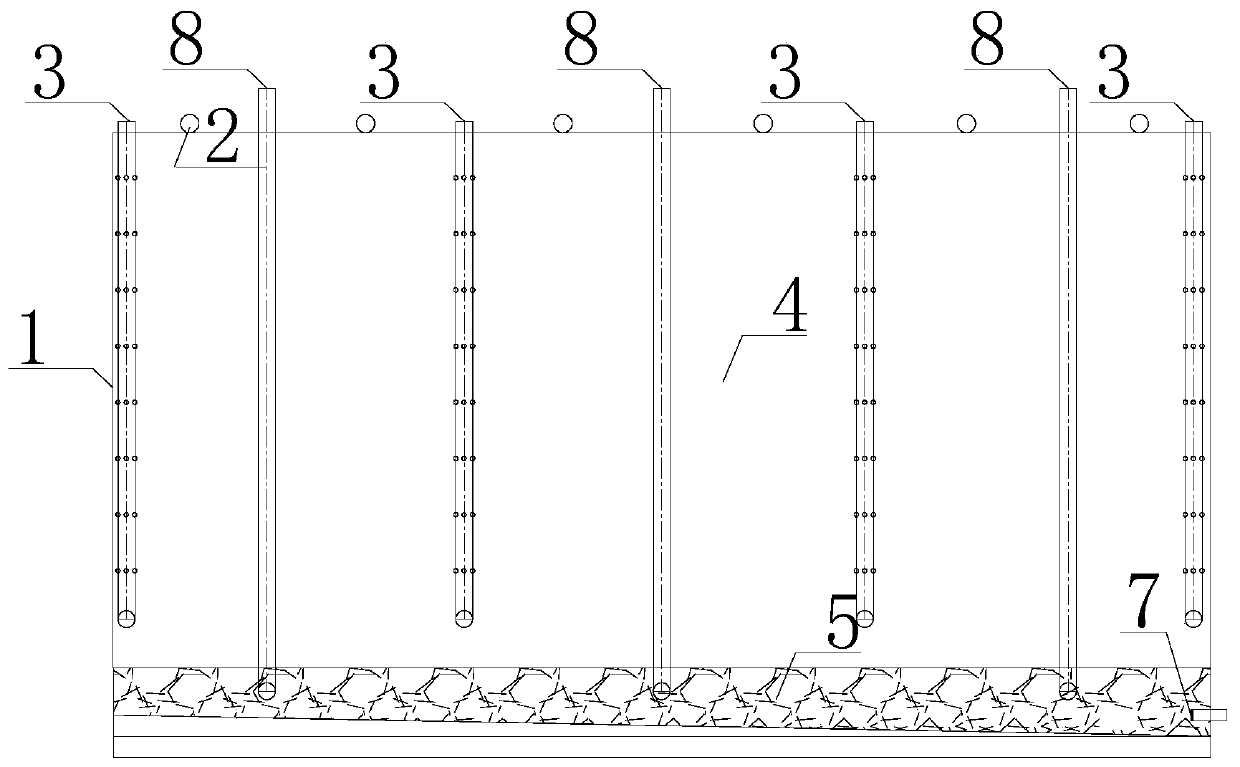

[0062] A treatment device for organic waste water, see figure 2 , including a reactor 1, a water distribution pipe 2, a plurality of mechanical ventilation pipes 3, a plurality of natural ventilation pipes 8, a filter bed 4 and a gravel layer 5.

[0063] The filter bed 4 is formed by filling GY-1 water treatment filler in the reactor 1, and the bottom of the filter bed 4 is provided with a crushed stone layer 5, and the natural ventilation pipe 8 and the mechanical ventilation pipe 3 are vertically inserted into the filter bed 4; the water distribution pipe 2 is set at the top of Reactor 1. Further, the area and thickness of the filter bed 4 are determined according to the daily water inflow, the area of the filter bed 4 is 8-10 times of the daily water inflow, and the area of the filter bed 4 is 400-500m 2 , to determine the thickness of the filter bed 4 is 1.5m ~ 2m.

[0064] Further, the water distribution pipe 2 is arranged on the top of the reactor 1, and the waste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com