In-situ water body remediation material adopting natural minerals

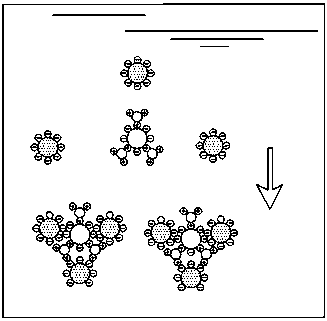

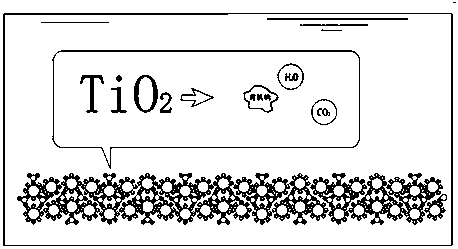

A water body remediation and natural mineral technology, applied in sustainable biological treatment, polluted waterway/lake/pond/river treatment, aerobic process treatment, etc. Diffusion, evolution and export of pollutants in water, to achieve the effect of improving habitat environment, wide application range and preserving biodiversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

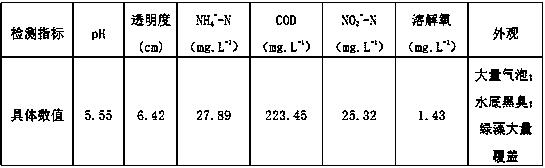

Examples

Embodiment 1

[0037] Example 1 A preparation method of a natural mineral in-situ water body restoration material includes the following steps:

[0038] 4 parts of volcanic ash, 4 parts of dolomite, 62 parts of clinoptilolite, 7 parts of rock-forming minerals, and 6 parts of clay minerals with high ion exchange capacity are pulverized separately, and the sieved powders with a particle size of 300 mesh or less are thoroughly mixed. The mixed powder was heated to 160° C. and maintained, and pulverized again for 40 minutes to prepare the natural mineral in-situ water body restoration material (powder) of this embodiment.

[0039] In this example, the cation replacement capacity of clinoptilolite was 230-255meq / 100g, and the specific surface area was 550-650m. 2 / g; The volcanic ash is selected from aluminum volcanic ash in Kyushu, Japan; the rock-forming mineral is a mixture of quartz, muscovite, and feldspar; the mass ratio of quartz, muscovite, and feldspar in the rock-forming mineral mixture is 3....

Embodiment 2

[0041] Example 2 A preparation method of a natural mineral in-situ water body restoration material includes the following steps:

[0042] 8 parts of volcanic ash, 7 parts of dolomite, 70 parts of clinoptilolite, 8 parts of rock-forming minerals, and 10 parts of clay minerals with high ion exchange capacity are pulverized separately, and the sieved powders with a particle size of 300 mesh or less are thoroughly mixed. The mixed powder was heated to 160° C. and maintained, and pulverized again for 30 minutes to prepare the natural mineral in-situ water restoration material (powder) of this embodiment.

[0043] In this embodiment, the cation replacement capacity of clinoptilolite is 230-255meq / 100g, and the specific surface area is 550-650m2 / g; the volcanic ash is selected from aluminum volcanic ash from Kyushu, Japan; the rock-forming mineral is a mixture of quartz, muscovite, and feldspar; The mass ratio of quartz, muscovite and feldspar in the mineral mixture is 5.4:8.3:7.1; the we...

Embodiment 3

[0045] Example 3 A preparation method of a natural mineral in-situ water body restoration material includes the following steps:

[0046] 11 parts of volcanic ash, 8 parts of dolomite, 72 parts of clinoptilolite, 9 parts of rock-forming minerals, and 15 parts of clay minerals with high ion exchange capacity are pulverized separately, and the sieved powders with a particle size of 300 mesh or less are thoroughly mixed. The mixed powder was heated to 170° C. and maintained, and pulverized again for 35 minutes to prepare the natural mineral in-situ water body restoration material (powder) of this example.

[0047] In this embodiment, the cation replacement capacity of clinoptilolite is 230-255meq / 100g, and the specific surface area is 550-650m2 / g; the volcanic ash is selected from aluminum volcanic ash from Kyushu, Japan; the rock-forming mineral is a mixture of quartz, muscovite and feldspar; The mass ratio of quartz, muscovite and feldspar in the mineral mixture is 6.0:9.0:7.9; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com