Finishing method for silk fiber cotton cloth

A technology of silk fiber and cotton cloth, applied in the direction of fiber processing, plant fiber, animal fiber, etc., can solve the problems of short use time, easy to be eaten by insects, etc., and achieve the effect of prolonging the service life and good finishing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

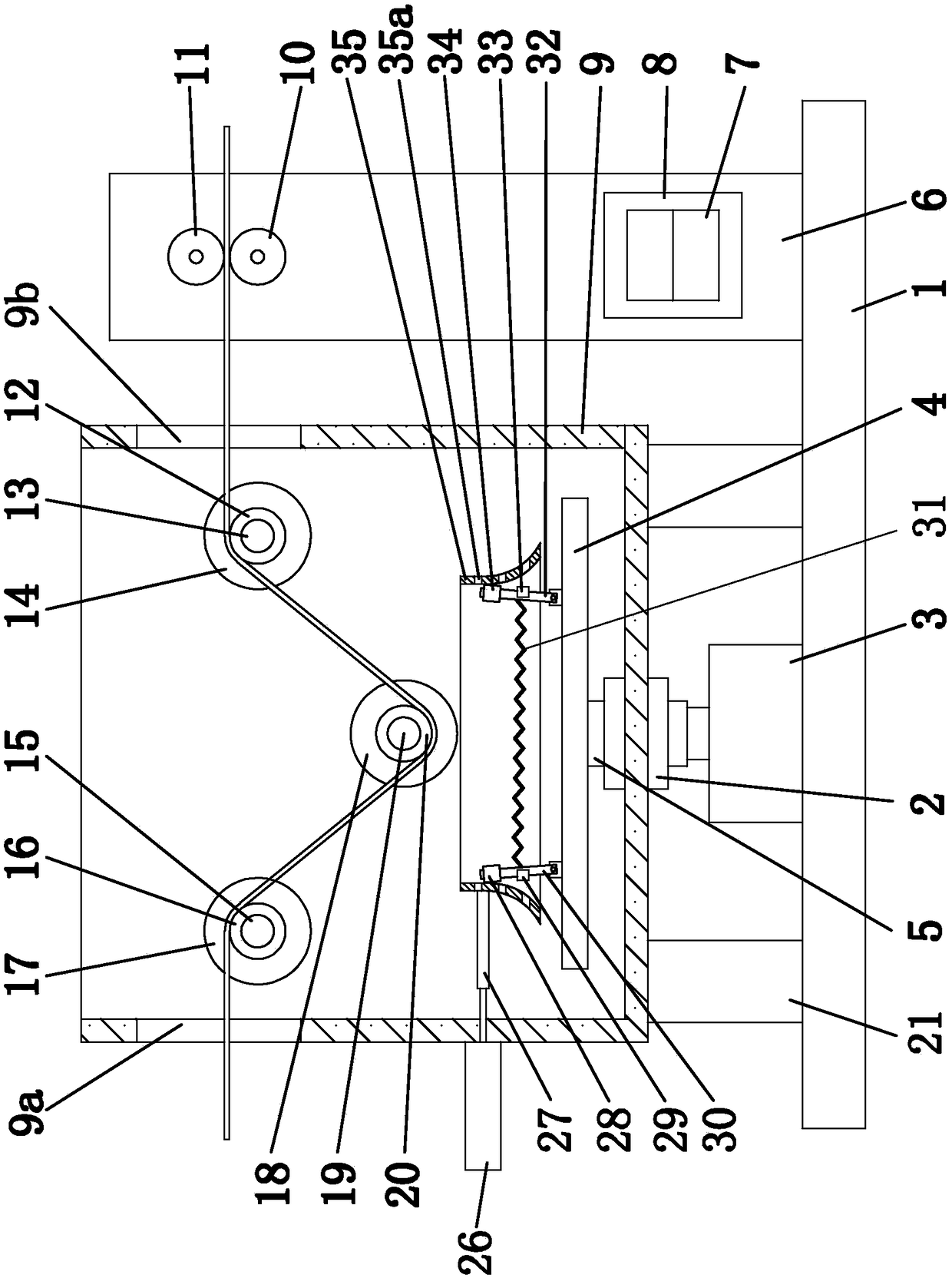

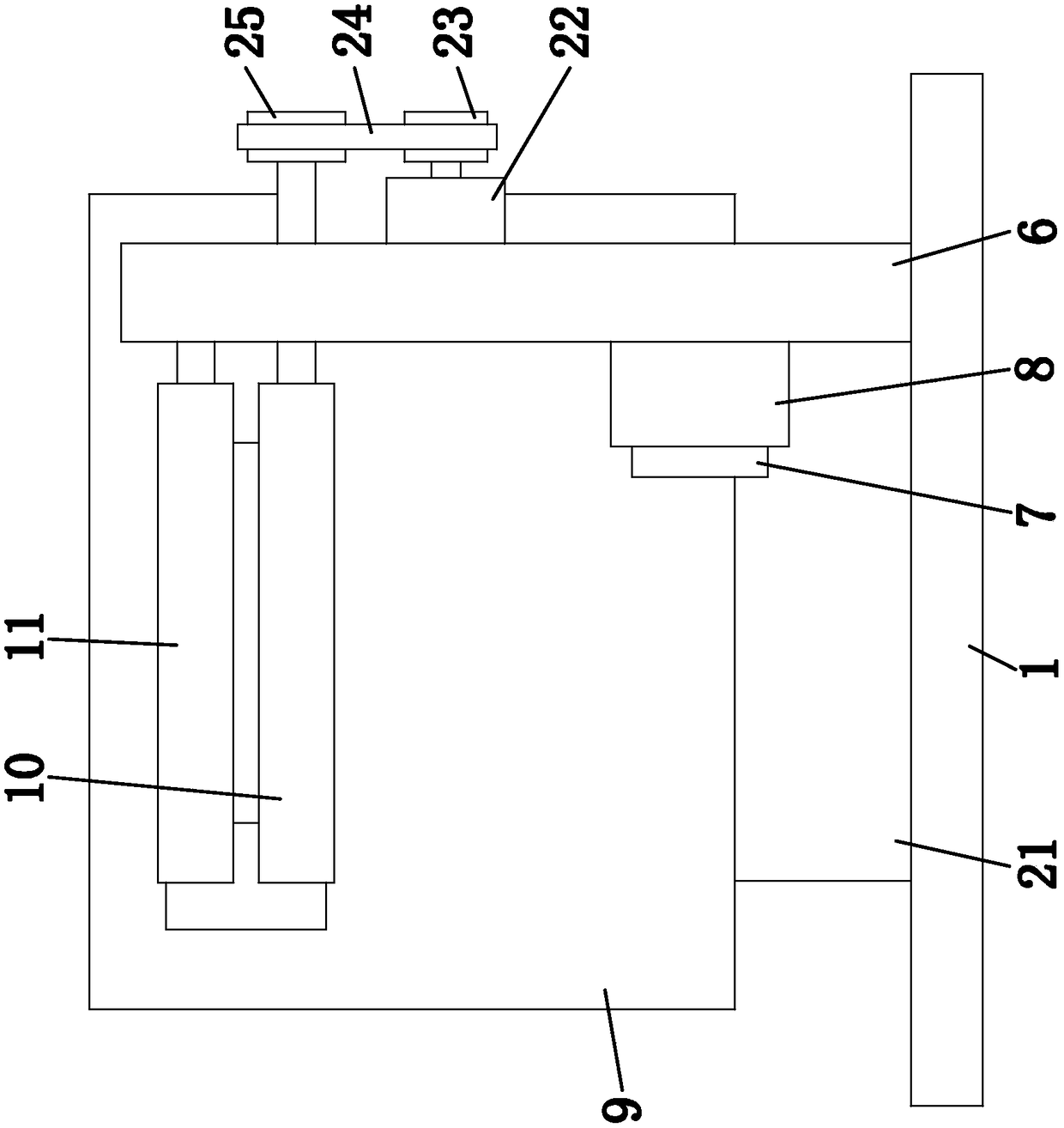

[0036] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0037] The finishing method of this silk fiber cotton cloth comprises the following steps:

[0038] a. In parts by weight, 5-8 parts of sodium aluminum fluorosilicate, 6-12 parts of glycerin, 14-20 parts of water-absorbing silica gel, 8-14 parts of betel nut, 1.5-3.5 parts of anti-aging agent, resmethrin 10 to 20 parts, 4 to 9 parts of camphor powder, 1 to 3 parts of antifungal agent and 60 to 90 parts of water are put into a blender and stirred evenly to obtain a finishing liquid; in the present embodiment, by weight parts, 6 parts of sodium aluminum fluorosilicate, 8 parts of glycerin, 17 parts of water-absorbing silica gel, 12 parts of betel nut, 1.9 parts of anti-aging agent, 13 parts of resmethrin, 5 parts of camphor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com