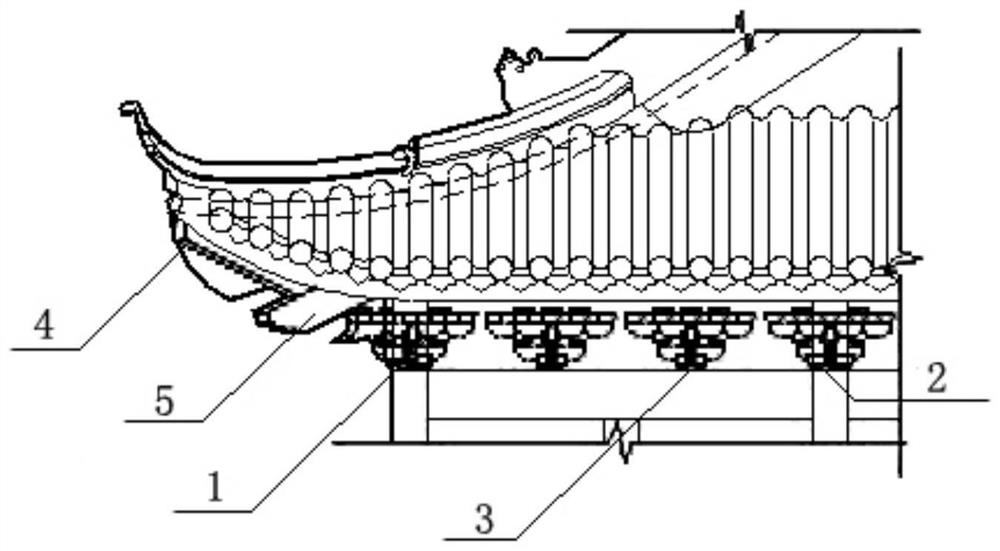

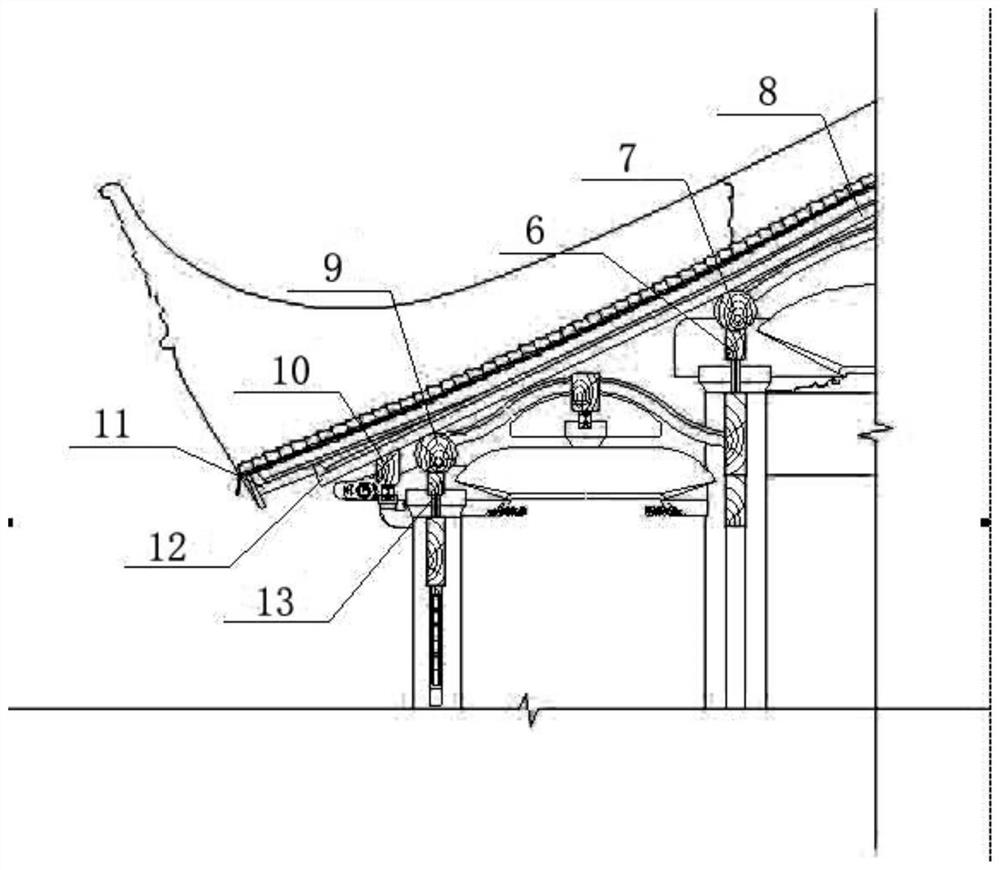

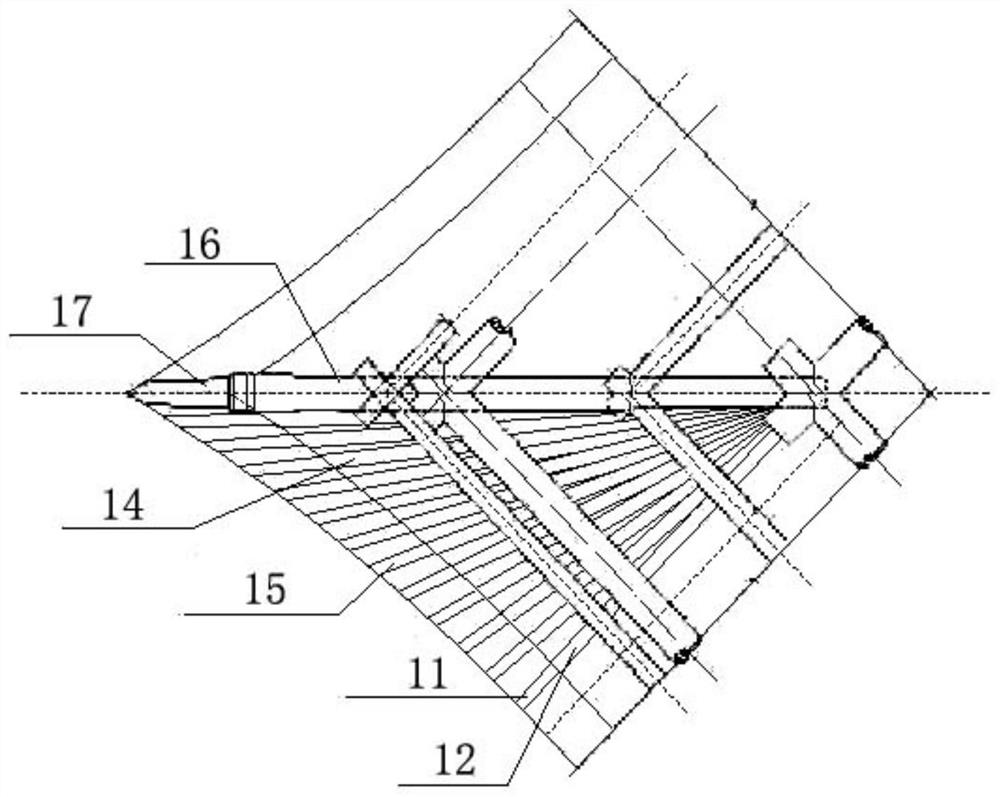

Pseudo-classic architecture concrete cornice roof component mounting construction method

A technology of roof components and construction methods, which is applied to building roofs, building structures, roofs, etc., can solve problems such as inability to achieve refinement, mass production, industrialized green construction, limited natural wood resources, fire prevention, and corrosion defects, etc., to achieve Short construction period, simple process, good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0028] The invention provides a method for installing and constructing concrete eaves and roof components of an antique building, which comprises the following steps:

[0029] 1. Preliminary preparation

[0030] The CAD electronic version of the construction drawing reviewed by the drawing review agency is sent to the processing shed or prefabrication plant.

[0031] 2. Construction of concrete foundation and frame main structure

[0032] While the foundation and main structure of the antique building are being constructed on the construction site, the components of the processing shed or prefabricated factory are manufactured in a modular manner. The principle is less specifications and more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com