Phosphate buffer solution and preparation method thereof

A phosphate buffer and buffer technology are applied in the field of phosphate buffer and its preparation, which can solve problems such as adverse effects of test results, and achieve the effects of reducing endotoxin load, simple configuration process and reducing fever reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

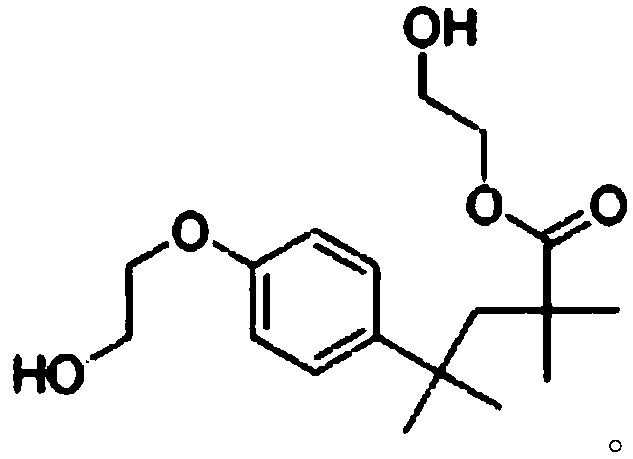

Method used

Image

Examples

preparation example Construction

[0031] The preparation experimental apparatus of concentrate phosphate buffer solution is as follows:

[0032] (1) Stirrer;

[0033] (2) Digital thermostat;

[0034] (3) pH meter;

[0035] (4) Conductivity meter;

[0036] (5) 5L large volume cup;

[0037] (6) The test sample is placed in a 100ml small beaker;

[0038] (7) Insert the electrodes of the pH meter and conductivity meter into the solution after calibration;

[0039] (8) Press the "reading" button of the pH meter and the conductivity meter respectively;

[0040] (9) Wait for 1min-2min, record the reading on the pH meter and the reading on the conductivity;

[0041] (10) Dilute the concentrated solution again, dilute it 10 times, test the diluted solution on the machine, and compare and analyze it with some original technical indicators.

[0042] Citation: YYT 0456.1-2014 Reagents for blood analyzers Part 1: Cleaning solution; YYT 0456.3-2014 Reagents for blood analyzers Part 3: Diluents; ISO18113-2 Part 2: In ...

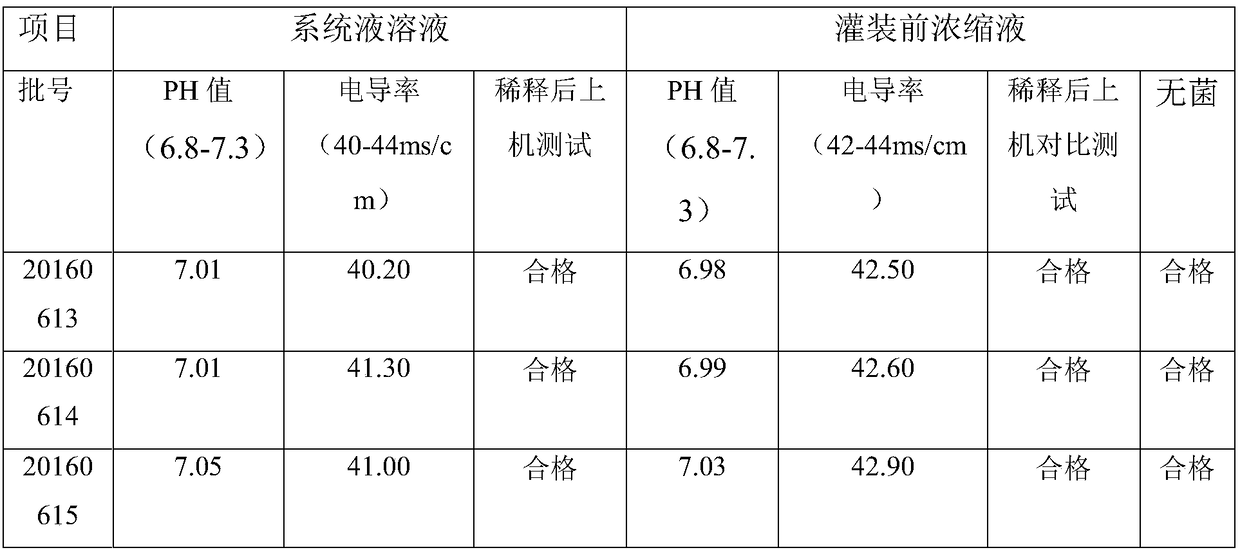

Embodiment 2

[0048]1. Put 3000ml of ultra-pure water in a 5000ml measuring cup (the volume needs to be calibrated, it has been calibrated), put the measuring cup under the stirrer, let the stirring rod extend to 1 / 2 of the liquid surface, set the stirring frequency to 55HZ, and start stirring , then add 0.56% potassium dihydrogen phosphate, 2.38% disodium hydrogen phosphate dihydrate, 1.40% potassium chloride, 0.197% sodium nitrate, 0.39% EDTA-2Na (dihydrate) and 0.053 TritonX-100 to the 5000ml measuring cup. %, K40 0.12%, each time you add a chemical, you must wait for it to dissolve completely before adding the next chemical, and wait until the above chemicals are completely dissolved, and then fill up the 5L measuring cup to the mark (already Calibrated scale line), continue to stir, after the stirring is finished, the solution can be sterilized and filtered to obtain the required concentrated solution,

[0049] 2. Stand still for 1 hour to obtain the pre-filling solution. The obtained ...

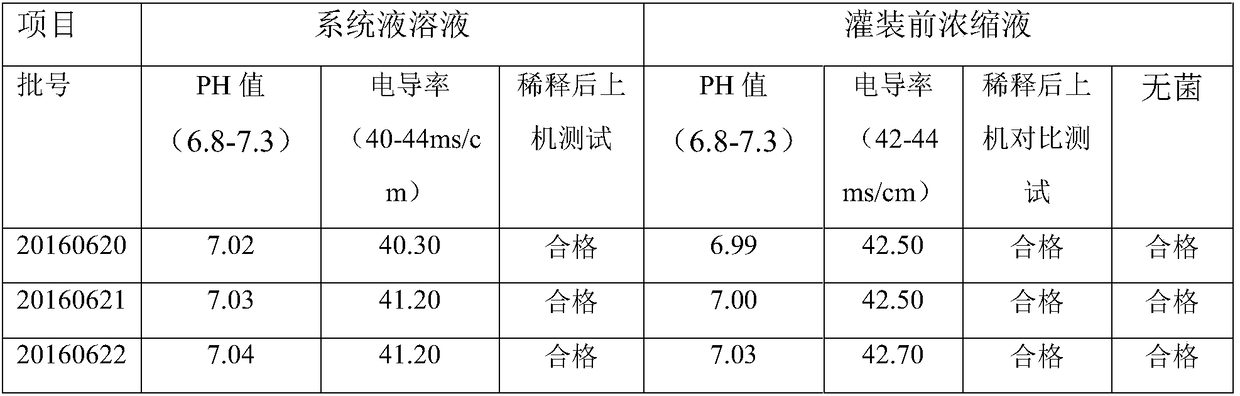

Embodiment 3

[0053] 1. Put 3000ml of ultra-pure water in a 5000ml measuring cup (the volume needs to be calibrated, it has been calibrated), put the measuring cup under the stirrer, let the stirring rod extend to 1 / 2 of the liquid surface, set the stirring frequency to 60HZ, and start stirring , then add potassium dihydrogen phosphate 0.57%, disodium hydrogen phosphate dihydrate 2.39%, potassium chloride 1.55%, sodium nitrate 0.197%, EDTA-2Na (dihydrate) 0.36%, TritonX-100 0.055 to the 5000ml measuring cup successively %, K40 0.13%, every time you add a chemical, you must wait for it to completely dissolve and then add the next chemical. After the above chemicals are completely dissolved, then fill up the 5L measuring cup to the mark (already Calibrated scale line), continue to stir, after the stirring is finished, the solution can be sterilized and filtered to obtain the required concentrated solution,

[0054] 2. Stand still for 1 hour to obtain the pre-filling solution. The obtained con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com