Deep in-situ in-hole shearing testing system and testing method thereof

A testing system and internal shearing technology, applied in the direction of using stable shear force to test material strength, using stable tension/pressure to test material strength, etc., can solve the problem that the shear rate and readings have great influence and affect the test results. Accuracy, borehole wall collapse, etc., to achieve the effect of good integrity and stability, accurate and reliable test data, and improve quality and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

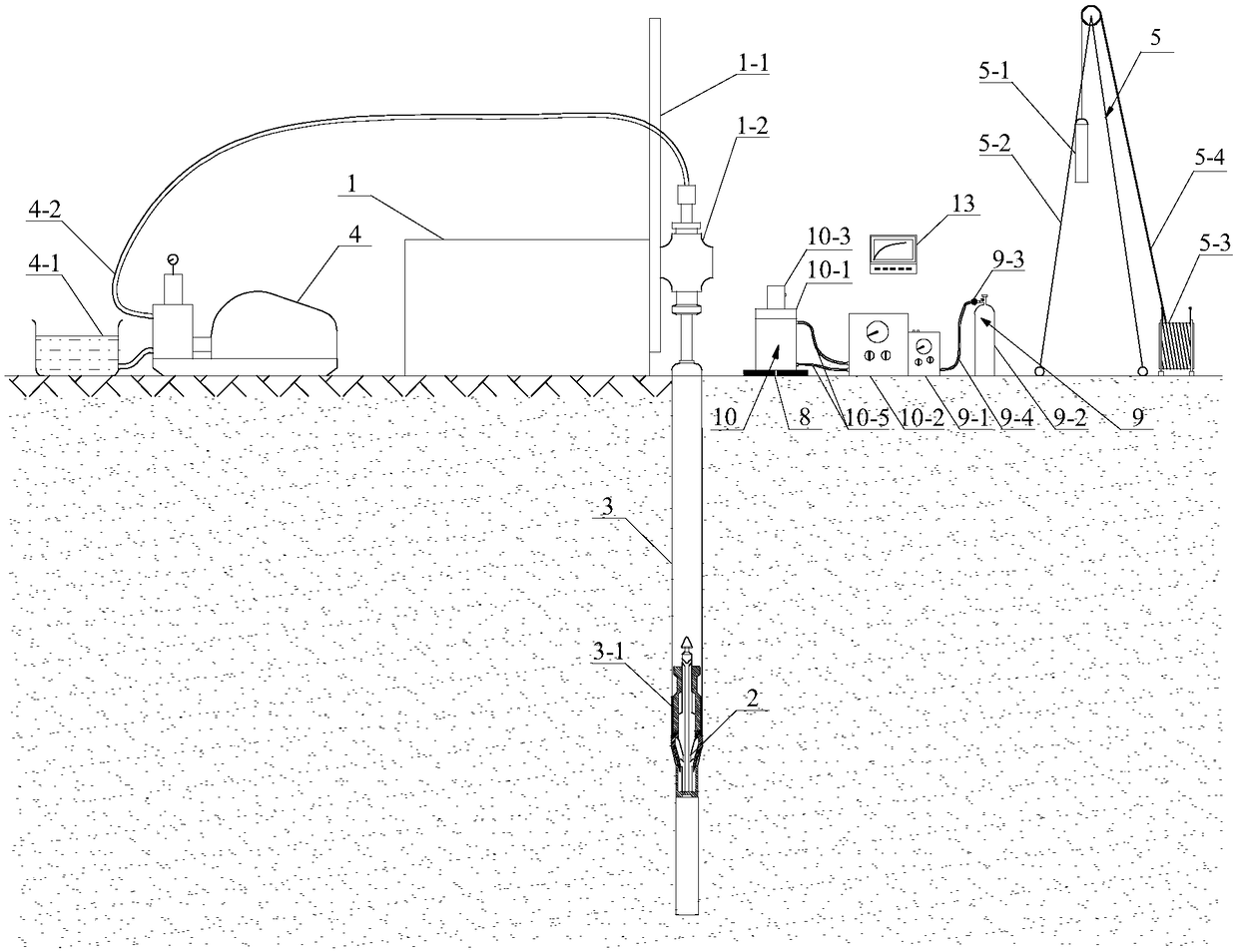

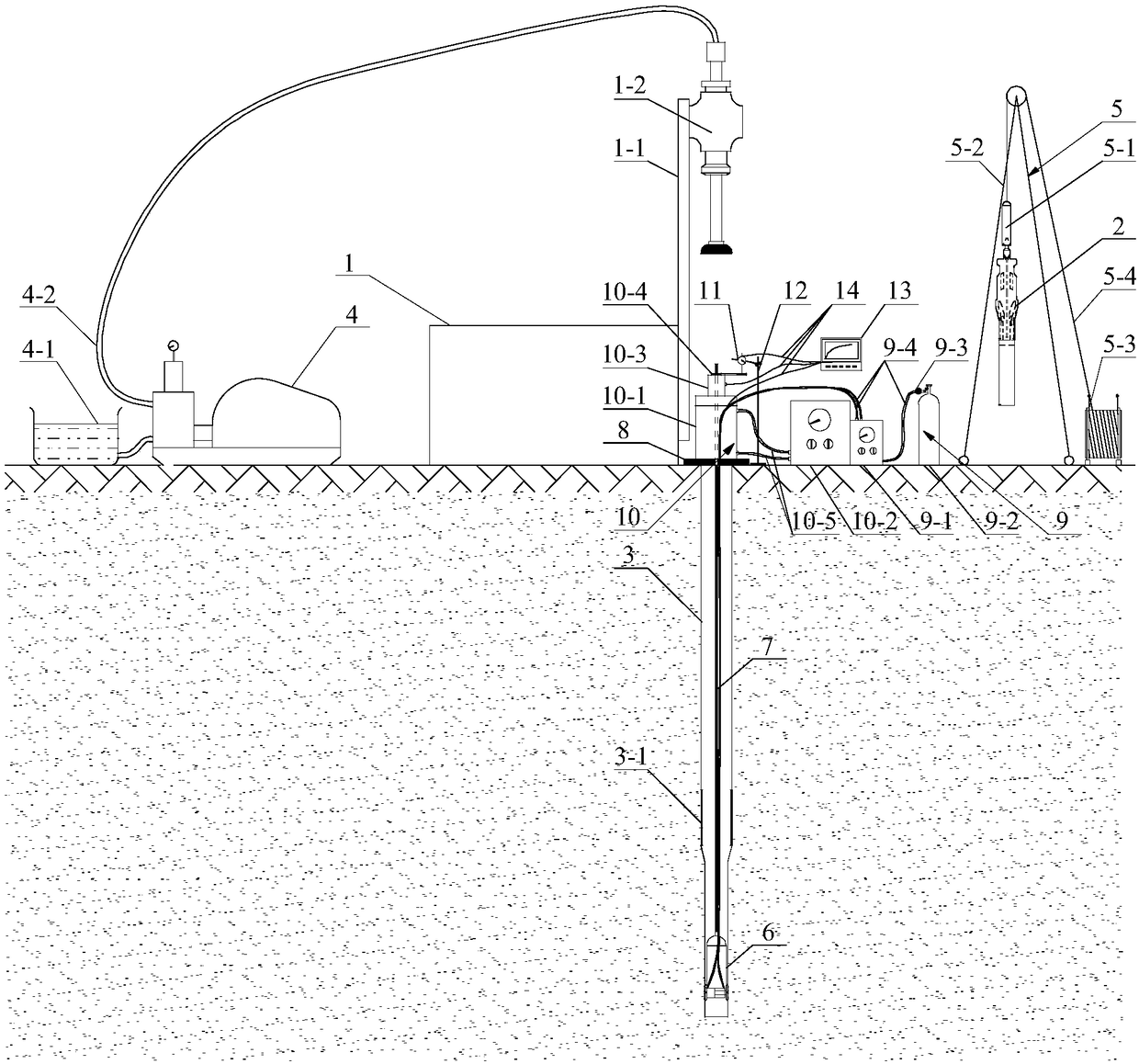

[0061] The deep in-situ in-hole shear test system and its test method of the present invention will be described in detail below with reference to the accompanying drawings.

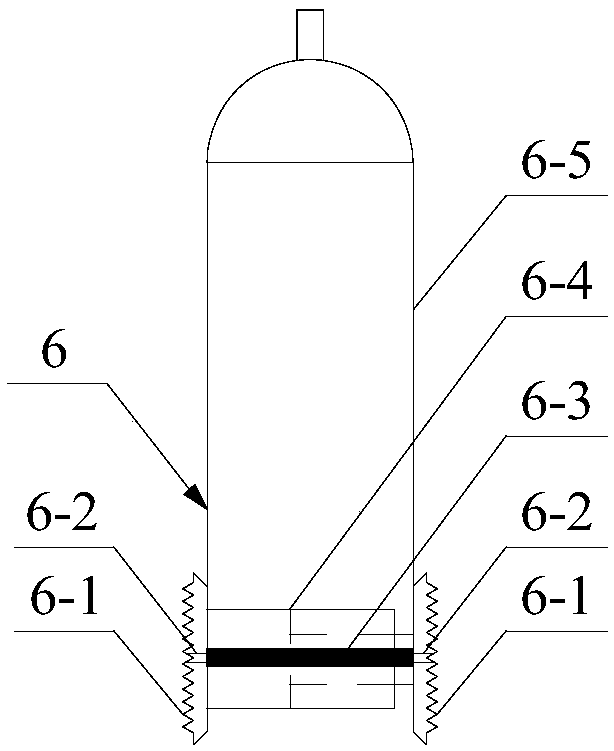

[0062] Such as figure 1 and figure 2 As shown, the deep in-situ in-hole shear test system of the present invention includes: a drilling rig 1, a tensioned casing core drilling tool, a casing 3, a mud pump 4, a drilling tool fishing device 5, a shear probe 6, and a pull rod 7. Reaction base plate 8, normal stress load measurement device 9, shear stress load measurement device 10, dial indicator 11, magnetic meter frame 12, data acquisition recorder 13 and data cable 14.

[0063] The drilling rig 1 includes a drilling tower 1-1 and a power head 1-2, which are used to drive the casing 3 and the positioning end pipe 3-1 at the bottom of the casing 3 to drill into the formation. The positioning end pipe 3-1 is used to drive the tensioned casing core drilling tool 2 for drilling and sampling. After drilling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com