Preparing method for butyronitrile-particle anti-sliding glove

A technology of styrene-butadiene particles and gloves, applied in gloves, protective clothing, textiles and papermaking, etc., can solve the problems of polluted environment, latex damage, and inability to use chemical patterning, etc., to ensure wear resistance, improve friction, and increase durability. operational effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

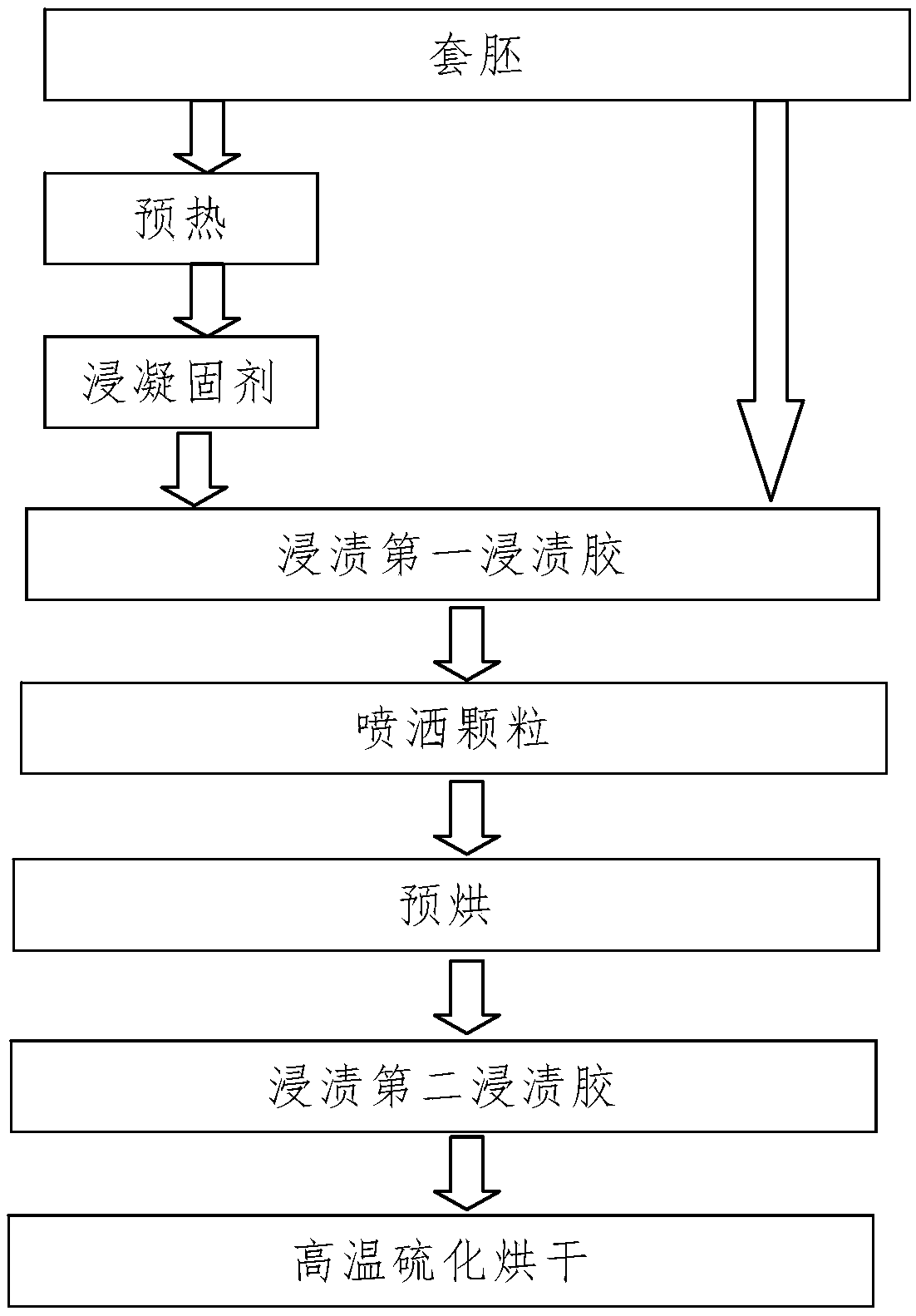

Method used

Image

Examples

Embodiment 1

[0033] Step 1, raw material preparation: presulfurized carboxyl nitrile latex, thickener of purchasing on the market: dry complexin aqueous solution (massfraction is 12%), purchasing nitrile particle (order number is 30 orders) on the market

[0034] Step 2, glue adjustment:

[0035] Pre-dipping glue: slowly add the thickener in step 1 into the pre-vulcanized carboxylated nitrile latex under stirring, and adjust the stirring speed so that there are no air bubbles, so that the viscosity is 500mpa·s;

[0036] The first dipping rubber: slowly add the thickener in step 1 to the pre-vulcanized carboxylated nitrile latex under stirring, and adjust the stirring speed so that its viscosity is 4000mpa·s;

[0037] The second dipping glue: slowly add the thickener in step 1 into the pre-vulcanized carboxylated nitrile latex under stirring, and adjust the stirring speed to make its viscosity 400mpa·s;

[0038] Step 3. Glue dipping: put the flannelette glove embryo on the hand mold, immer...

Embodiment 2

[0044] Step 1, raw material preparation: prevulcanized nitrile latex, thickener sodium carboxymethyl cellulose solution (mass fraction is 2%) and cellulose sodium solution (mass fraction is 2%), styrene-butadiene particles (order number is 50 head)

[0045] Step 2, glue adjustment:

[0046] The first dipping glue: slowly add the sodium carboxymethylcellulose solution in step 1 to the pre-vulcanized nitrile latex under stirring, and adjust the stirring speed to make its viscosity 4200mpa·s;

[0047] The second dipping glue: slowly add the sodium cellulose solution in step 1 to the pre-vulcanized nitrile latex under stirring, and adjust the stirring speed to make its viscosity 800mpa·s;

[0048] Step 3, dipping: put the cotton wool glove embryo on the hand mold, and dip into the first dipping glue in step 2;

[0049]Step 4, spraying particles: evenly sprinkle the particles in step 1 on the gloves soaked in step 3;

[0050] Step 5, pre-drying: pre-dry the sprayed impregnated g...

Embodiment 3

[0054] Step 1, raw material preparation: pre-vulcanized carboxyl nitrile latex (the content of acrylonitrile is 30%), thickener: sodium polyacrylate aqueous solution (mass fraction is 1.5%), natural rubber particles (order number is 60 orders)

[0055] Step 2, glue adjustment:

[0056] The first dipping rubber: slowly add the thickener in step 1 to the pre-vulcanized carboxylated nitrile latex under stirring, and adjust the stirring speed to 800rpm to make its viscosity 3800mpa·s;

[0057] The second dipping glue: slowly add the thickener in step 1 to the pre-vulcanized carboxylated nitrile latex under stirring, and adjust the stirring speed to make its viscosity 600mpa·s;

[0058] Step 3, dipping: put the chemical fiber glove blank on the hand mold, preheat to 50°C, dip into the coagulant, and then dip into the first dipping glue in step 2; wherein, the coagulant is methanol: calcium nitrate mass ratio is 100:5;

[0059] Step 4, spraying particles: evenly sprinkle the parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com