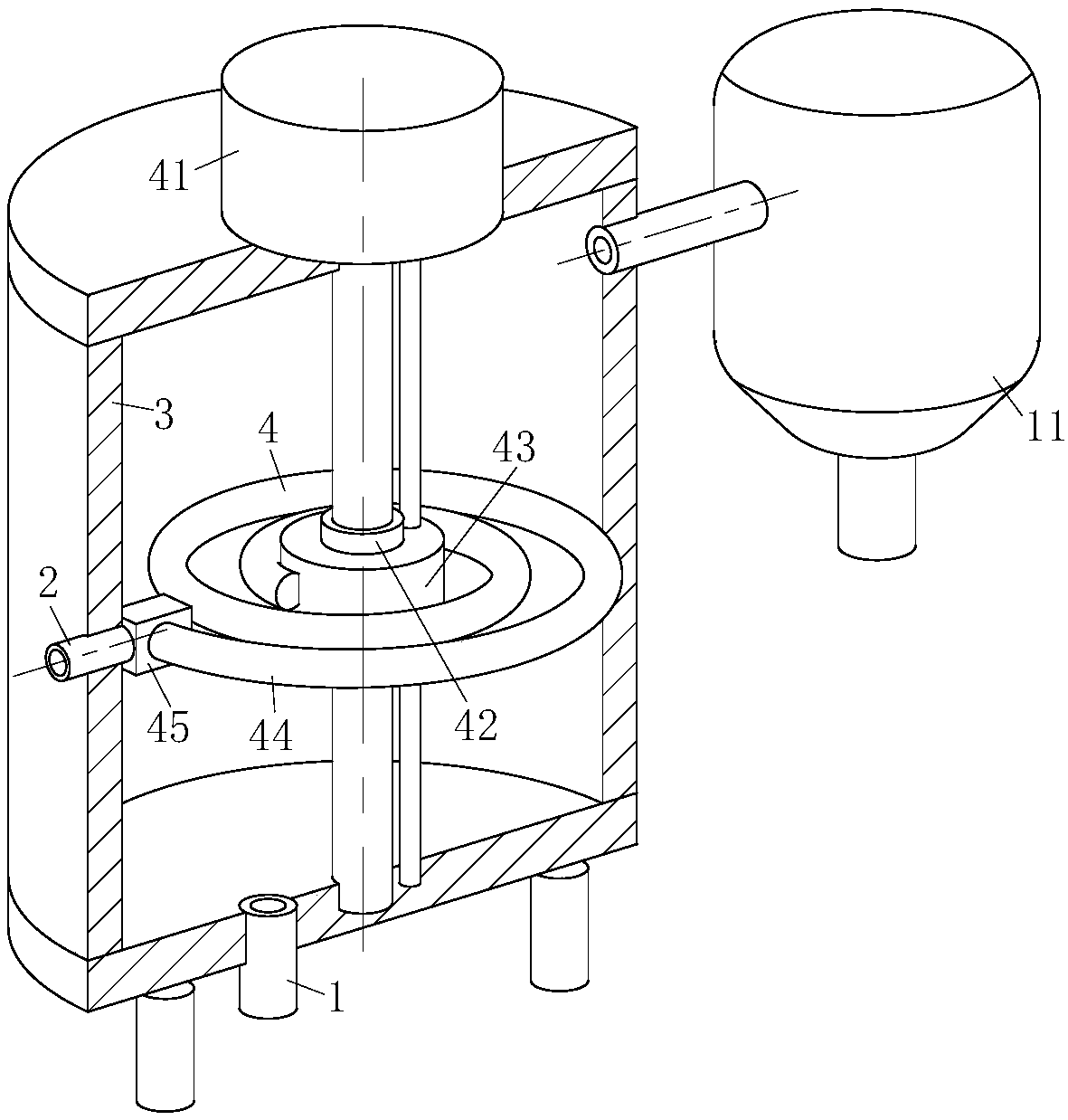

Thermal power plant SCR denitration reaction catalytic device

A technology of catalytic devices and thermal power plants, applied in the field of flue gas denitrification, can solve the problems of affecting reduction reaction, low efficiency, insufficient mixing of ammonia gas and flue gas, etc., and achieve the effect of avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

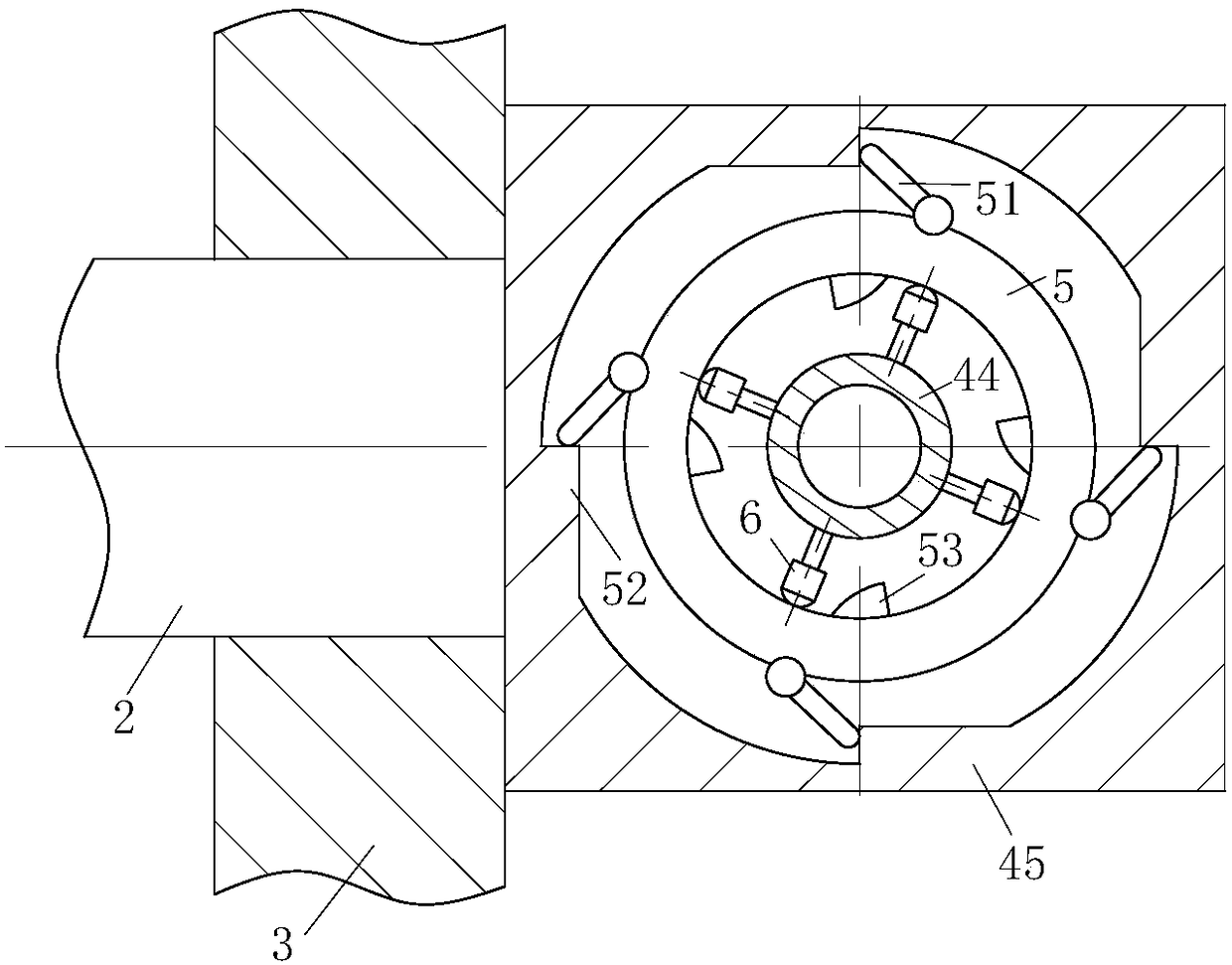

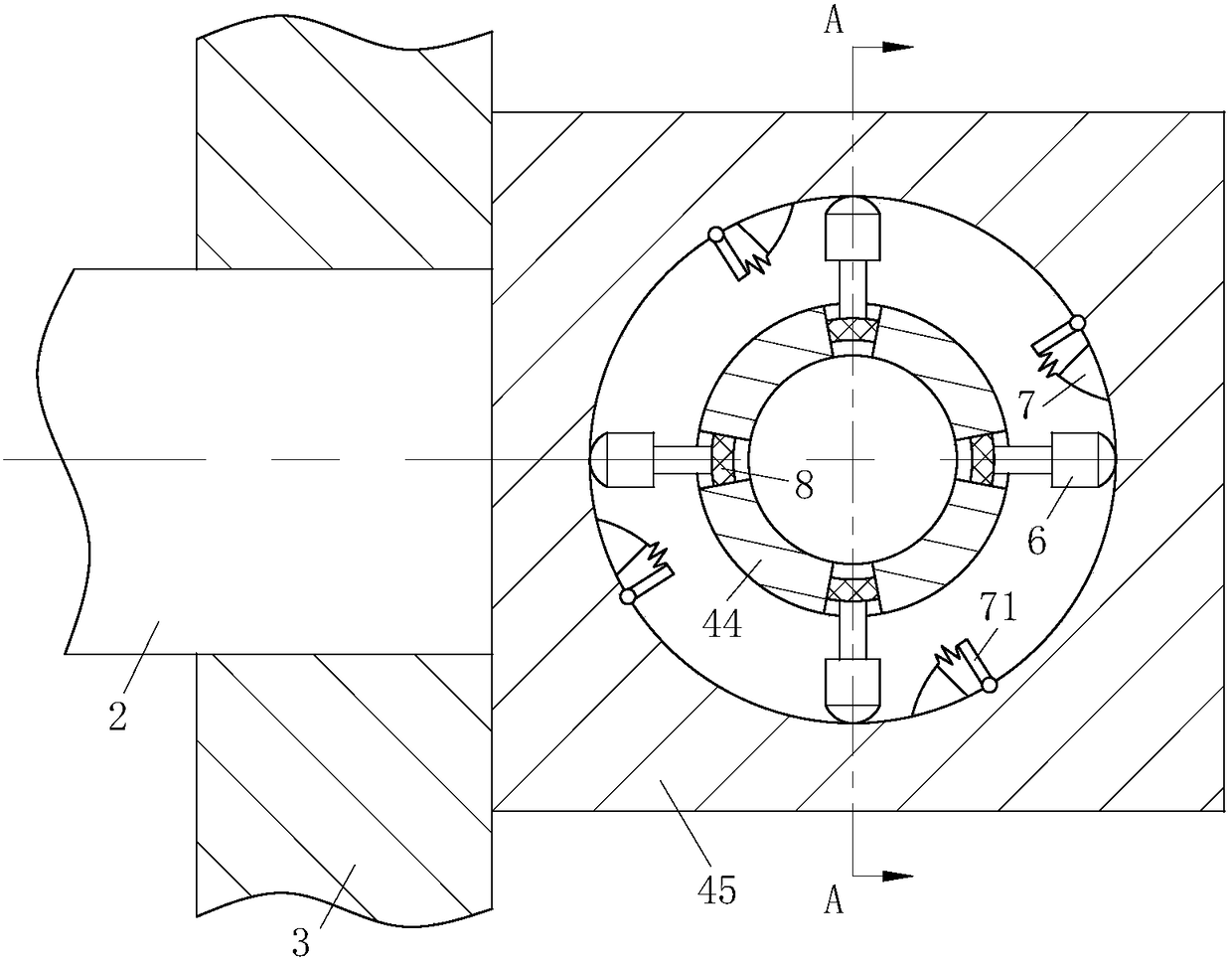

[0024] As an embodiment of the present invention, one end of the elastic helical tube 44 is rotatably installed in the mounting block 45 through the rotating ring 5, the rotating ring 5 is rotatably connected with the mounting block 45, and the outer ring of the rotating ring 5 is hinged to a set of rotating rods 51, a group of protrusions 52 are arranged on the inner wall of the circular cavity where the rotating ring 5 is installed, and the rotating rod 51 cooperates with the protrusions 52 to realize the one-way braking of the rotating ring 5; A step 53; a circular arc is set on one side of the step 53; a set of telescopic rods 6 is set on the outer ring of the end of the elastic spiral tube 44; the telescopic rods 6 can slide from one side of the step 53 to the other side. During work, in the process of traction and deformation of the elastic helical tube 44, a torsion force will be formed at the connection between the elastic helical tube 44 and the mounting block 45, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com