Foamed concrete stirring device

A technology of foamed concrete and mixing devices, which is applied to cement mixing devices, clay preparation devices, liquid ingredient supply devices, etc., can solve the problems of high foaming agent price, poor stability, and different sizes of bubbles, and achieve favorable The effect of mixing materials, saving costs and optimizing the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

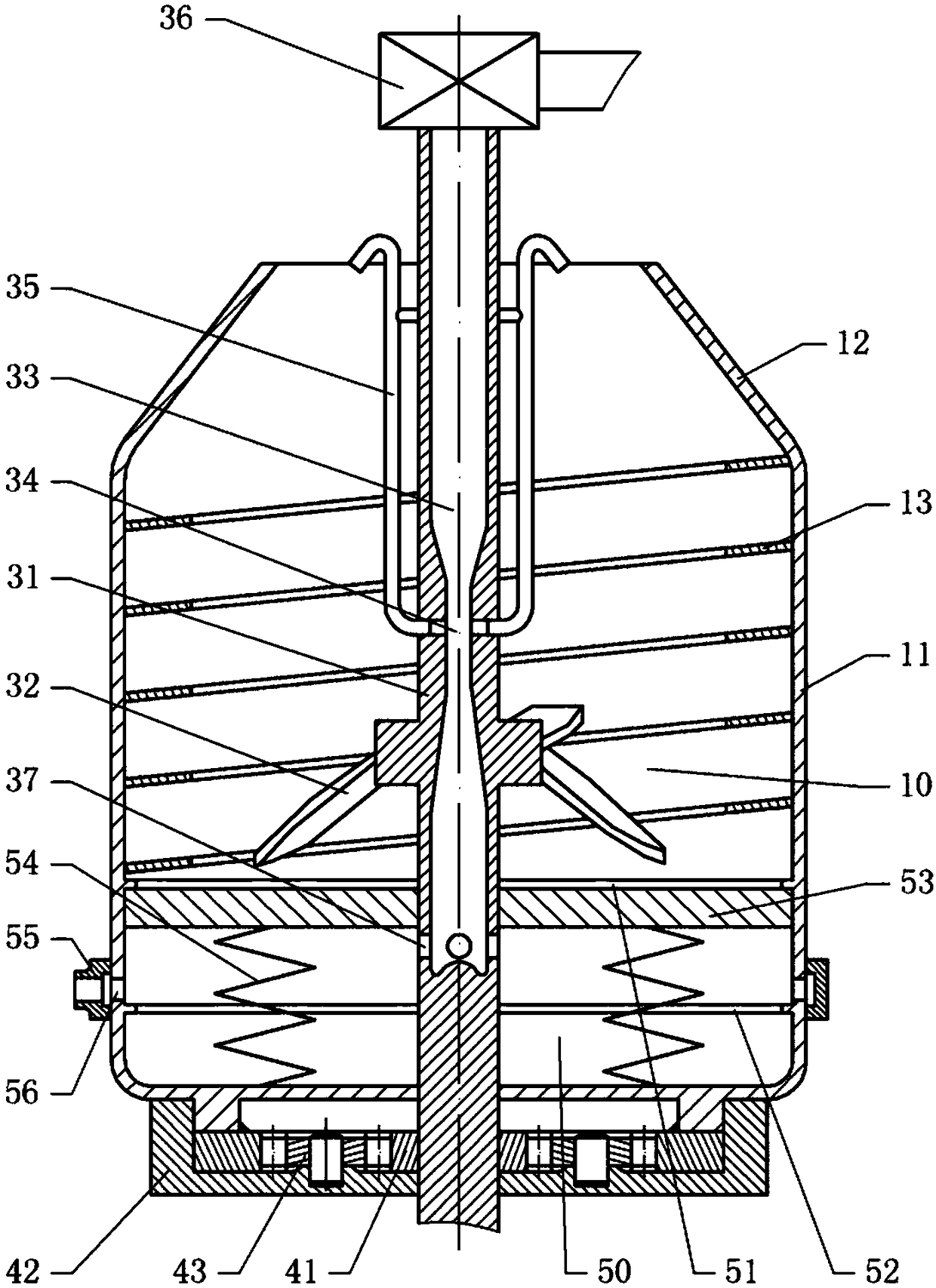

[0023] The reference signs in the accompanying drawings include: mixing drum 10, lower section 11, upper section 12, spiral guide piece 13, stirring shaft 31, stirring blade 32, water flow channel 33, throat 34, air inlet pipe 35, second rotary joint 36. Drain hole 37, sun gear 41, box body 42, planetary gear 43, wind cavity 50, upper rib 51, lower rib 52, partition 53, compression spring 54, first rotary joint 55, interface 56.

[0024] The embodiment is basically as figure 1 Shown:

[0025] The foamed concrete mixing device of this embodiment includes a mixing drum 10, a mixing mechanism, a driving part and a base; the mixing drum 10 is rotatably connected to the base, and the top of the mixing drum 10 is provided with an opening. The stirring mechanism comprises a stirring shaft 31 arranged in the stirring drum 10, the upper end of the stirring shaft 31 stretches out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com