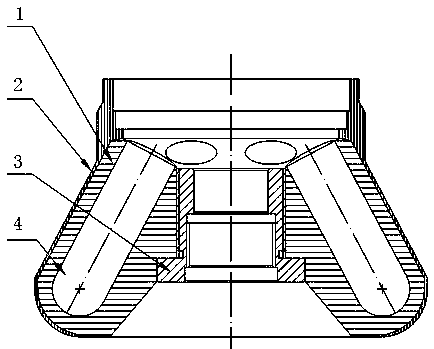

Manufacturing method of carbon fiber composite material centrifuge rotor

A centrifuge rotor and composite material technology, which is applied in the field of carbon fiber composite centrifuge rotor production, can solve the problems of failure to manufacture carbon fiber rotor products, radial cracking of rotor products, low rated speed, etc., and achieve light structure and easy use. Effect of long life and increased rated speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1. Use T300 grade carbon fiber unidirectional prepreg fabric with carbon fibers arranged in one direction in one direction as the raw material, and impregnate it with resin. The tensile strength of the fiber is 3800MPa, the tensile modulus of elasticity is 230MPa, and the resin is epoxy resin (or Phenolic resin), content 28%, prepreg thickness 0.15mm.

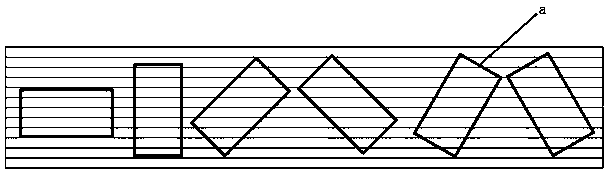

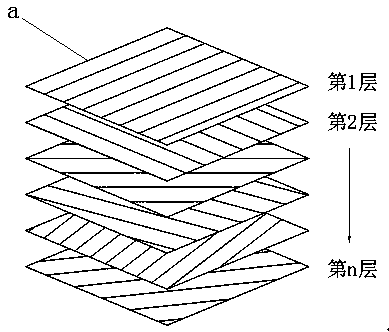

[0038] Step 2. Cut sheet a of the same size, such as 500mm×500mm, on the carbon fiber unidirectional prepreg at 0°, ±15°, ±30°, ±60°, and 90°, totaling 700 pieces, such as figure 2 shown; and then lay these carbon fiber unidirectional prepreg sheets a layer by layer to form a laminate, so that the fiber arrangement direction of each layer of prepreg in the laminate is distributed in the direction of 360 degrees, as shown in image 3 shown.

[0039] Step 3. Move the laminate to the middle of the two heating panels of the hot press, heat and press the laminate to form and solidify. The curing temperature, time and p...

Embodiment 2

[0045] Step 1. Use T700 grade carbon fiber unidirectional prepreg cloth with carbon fibers arranged in one direction in one direction as the raw material, and impregnate it with resin. The tensile strength of the fiber is 4700MPa, the tensile modulus of elasticity is 235MPa, and the resin is epoxy resin (or Bismaleimide resin), content 33%, prepreg thickness 0.25mm.

[0046] Step 2. Cut sheet a of the same size, such as 600mm×600mm, on the carbon fiber unidirectional prepreg at 0°, ±11.25°, ±22.5°, ±45°, and 90°, totaling 900 pieces, such as figure 2shown; and then lay these carbon fiber unidirectional prepreg sheets a layer by layer to form a laminate, so that the fiber arrangement direction of each layer of prepreg in the laminate is distributed in the direction of 360 degrees, as shown in image 3 shown.

[0047] Step 3. Move the laminate to the middle of the two heating panels of the hot press, heat and press the laminate to form and solidify. The curing temperature, tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com