Making technology for anti-radiation modal-fiber composite fabric

A modal fiber and composite fabric technology is applied in the field of radiation-proof modal fiber composite fabric production technology, which can solve problems such as single function, and achieve the effects of ensuring processing quality, improving processing efficiency, and improving production quality and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

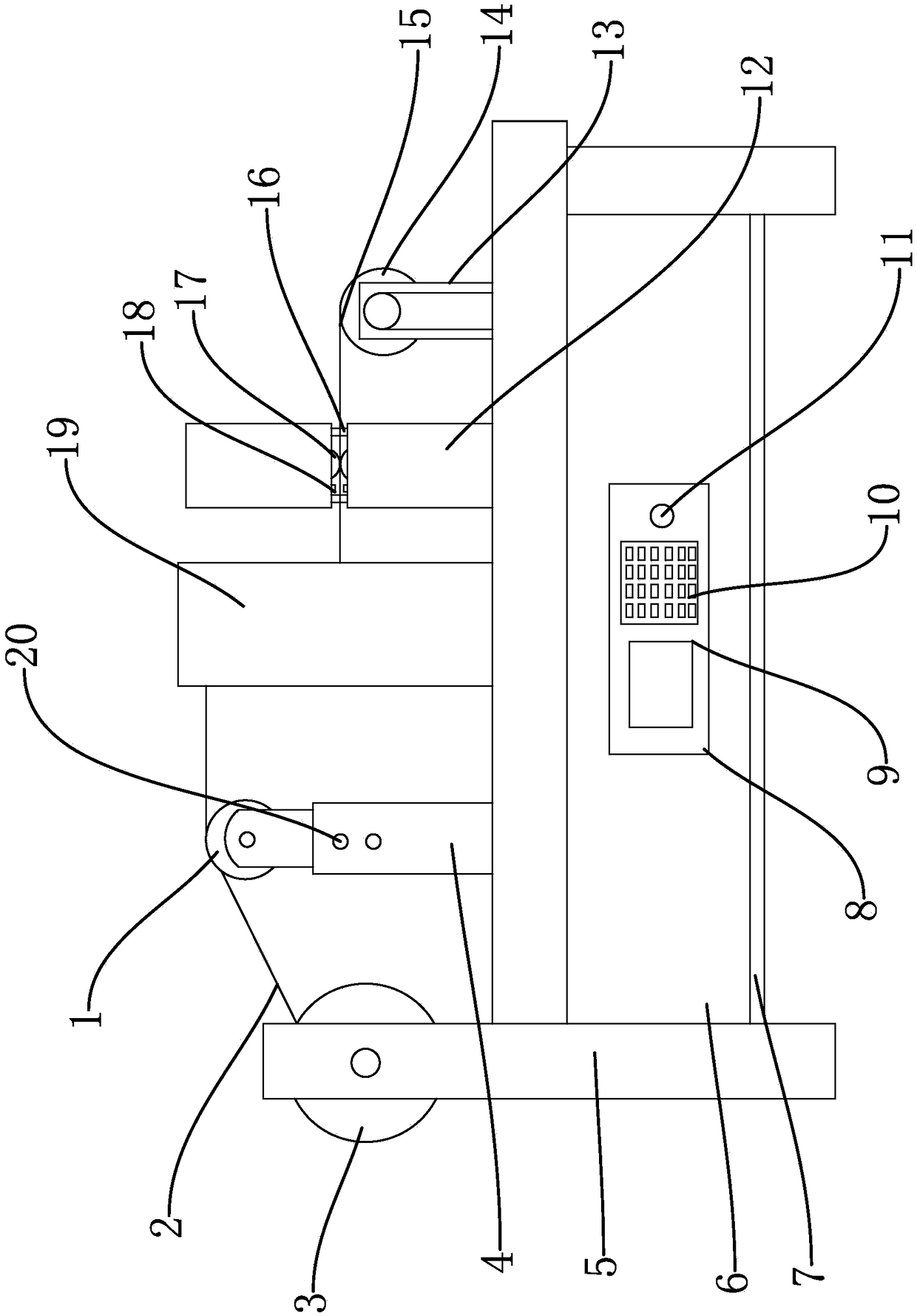

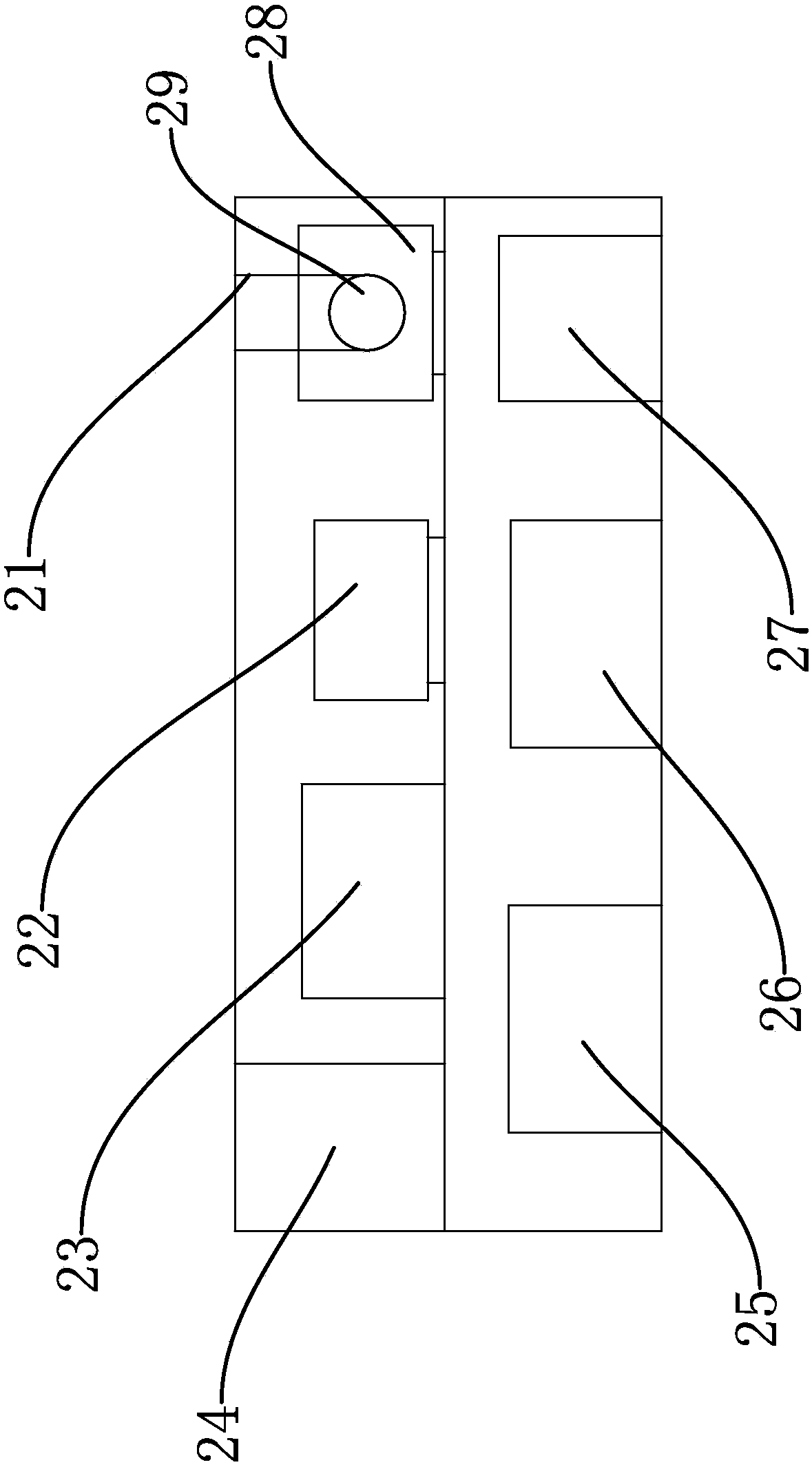

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

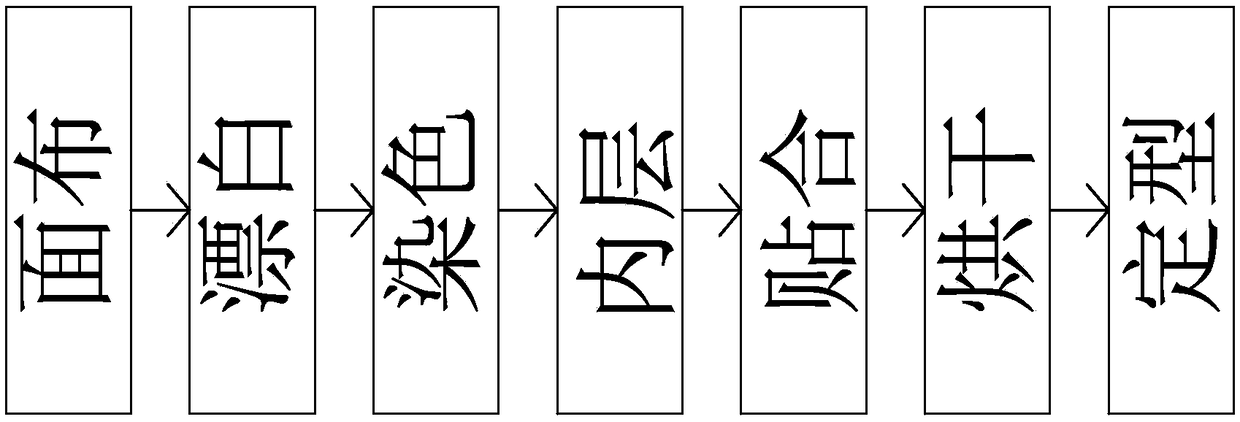

[0033] like Figure 1-4 Shown, a kind of anti-radiation type Modal fiber composite fabric manufacturing process, this manufacturing process comprises the following steps:

[0034] S1, face cloth: buy existing modal gray cloth from the market as face cloth;

[0035] S2, bleaching: put into water, bleaching agent, greasy dirt cleaning agent in the dipping tank, and bleaching agent is 10-20% of water weight percentage, and greasy dirt cleaning agent is 10-20% of water weight percent, the surface in S1 Put the cloth into the dipping tank for dipping and bleaching, and the bleaching time is 15-45 minutes;

[0036] S3, dyeing: put the face into the dyeing vat for dyeing, and the dyeing time is 4-6 hours;

[0037] S4. Inner la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com