Double-track slip support structures for large-span net rack assembly bed-jig platform

A supporting structure and large-span technology, which is applied in the direction of building structure, construction, and building material processing, can solve the problems affecting the construction period, cost of labor, and labor, and achieve the effects of convenient production, improved efficiency, and stable structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

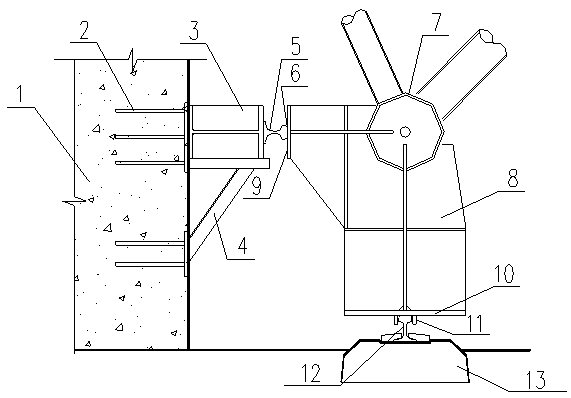

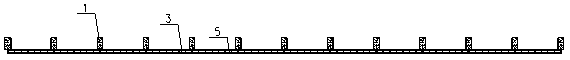

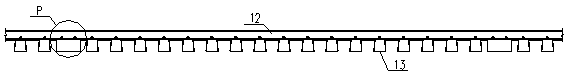

[0027] Baosteel Ironworks Phase I and Phase II Mixing Yard BA, BB and Auxiliary Yard OA, OB Closed Renovation Project. The project address is located in the raw material yard area of the third phase of Baosteel Co., Ltd. ironworks. The project structure is a space reticulated shell structure. The B-type closed stockyards of the BA and BB mixing yards of the project adopt three-core cylindrical reticulated shells with a span of 114.8 m, length 640m, height 51.5m, grid size 4.2m, reticulated shell thickness 3.75m, after considering the thickness of external purlins, the total thickness is about 4.25m. Adopt the form of lower chord support, according to the actual conditions provided by the site, the grid installation adopts the construction method of "cumulative assembly of the grid, and the gradual sliding of the tire frame", and erect the grid tire frame on the 1-3 / A-B axis of the mixing yard. Assembling platform, grid tire frame assembly platform is inside the A-B axis, the...

Embodiment 2

[0033] Except that the concrete column 1 is a post-installed steel embedded part, the others are the same as the embodiment 1.

[0034]The present invention has substantive features and significant technical progress. The double-rail sliding support structure of the large-span network frame assembly tire frame platform of the present invention is composed of the bottom support rail and the side support rail, forming the entire tire frame platform sliding system. , can realize the smooth sliding of the tire frame reticulated shell, improve the efficiency of sliding work, and ensure the progress requirements of the project.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com