Cigarette core material for heating incombustible cigarettes and preparation method thereof

A heat-not-burn and core technology, which is applied to smokers’ supplies, applications, tobacco, etc., can solve the problems of cigarette smoke quality not being strong enough, affecting the smoking experience, and uneven heating, so as to enhance the characteristic aroma of tobacco and improve Heating heating efficiency, avoiding the effect of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

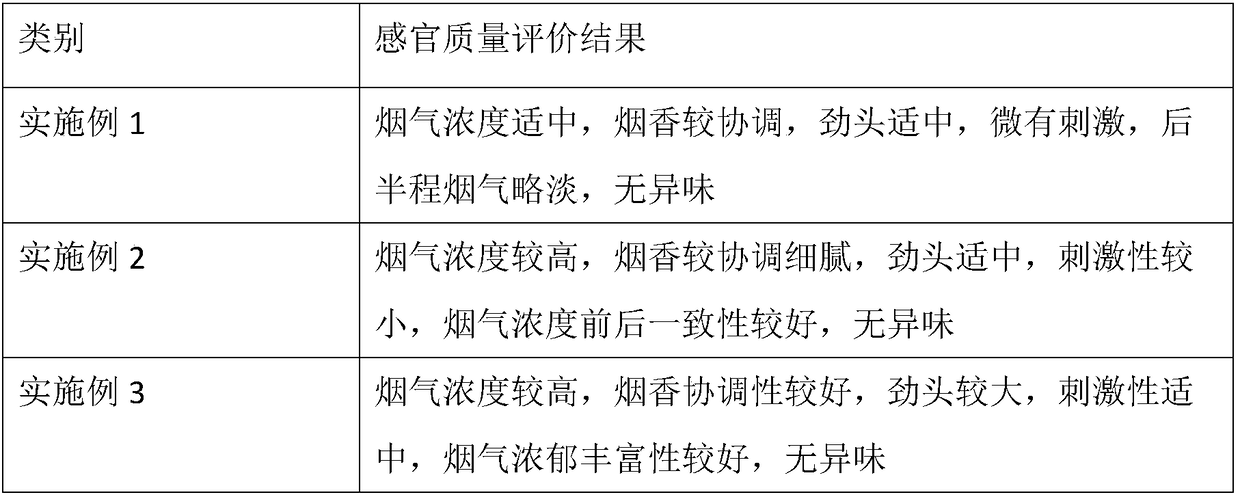

Examples

Embodiment 1

[0027] Raw material formula (by weight percentage): 35% of tobacco fiber and tobacco powder, 15% of wood pulp fiber, 10% of hemp fiber, 13% of smoking agent, 3% of carbon fiber, 4% of polyethylene glycol, and 15% of tobacco extract , Hydrophobic material 5%.

[0028] Preparation method: 1) Preparation of tobacco fiber and tobacco powder. Raw materials such as tobacco leaves, shredded tobacco, tobacco dust, tobacco stems, reconstituted tobacco leaves, and tobacco stalks are pulverized to form tobacco fibers and tobacco powder. Sieve, and take the part between 60-150 mesh.

[0029] 2) Preparation of cigarette core substrate. The tobacco fiber, tobacco powder and other raw materials are mixed together with water to form a paper-making slurry, and the paper base material of the cigarette core is prepared.

[0030] 3) Preparation of coating solution. Glyceryl triacetate, glyceryl caprylate, and higher fatty acids are uniformly mixed to form a coating liquid, which is a hydropho...

Embodiment 2

[0033] Raw material formula (by weight): 40% of tobacco fiber and tobacco powder, 10% of wood pulp fiber, 15% of hemp fiber, 10% of smoking agent, 3% of graphene, 2% of polypropylene glycol, 10% of tobacco extract, Microcapsule suspension 10%.

[0034] Preparation method: 1) Preparation of tobacco fiber and tobacco powder. Raw materials such as tobacco leaves, shredded tobacco, tobacco dust, tobacco stems, reconstituted tobacco leaves, and tobacco stalks are pulverized to form tobacco fibers and tobacco powder. Sieve, and take the part between 150 and 300 mesh.

[0035] 2) Preparation of cigarette core substrate. The tobacco fiber, tobacco powder and other raw materials are mixed together with water to form a paper-making slurry, and the paper base material of the cigarette core is prepared.

[0036] 3) Preparation of spray liquid. The glycerin triacetate is mixed evenly with the microcapsules containing the tobacco essence and the smoking agent, and the microcapsule suspe...

Embodiment 3

[0039] Raw material formula (by weight): 45% of tobacco fiber and tobacco powder, 10% of wood pulp fiber, 5% of hemp fiber, 2% of modified cellulose, 15% of smoke agent, 5% of silicon carbide, 3% of paraffin wax, Tobacco essential oil 10%, flavor suspension containing tobacco powder 5%.

[0040] Preparation method: 1) Preparation of tobacco fiber and tobacco powder. Raw materials such as tobacco leaves, shredded tobacco, tobacco dust, tobacco stems, reconstituted tobacco leaves, and tobacco stalks are pulverized to form tobacco fibers and tobacco powder. Sieve, and take the part between 60-80 mesh and 200-300 mesh.

[0041] 2) Preparation of cigarette core substrate. The tobacco fiber, tobacco powder and other raw materials are mixed together with water to form a paper-making slurry, and the paper base material of the cigarette core is prepared.

[0042] 3) Preparation of spray liquid. The tobacco essence and the tobacco powder are evenly mixed to prepare the essence suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com