High-weatherability matt wear-resistant imitated wood grain coextruded ASA alloy material and preparation method thereof

An alloy material and wood grain imitation technology, applied in the field of plastic materials, can solve the problems of poor wear resistance and weak wood feeling, and achieve the effects of strong wood feeling, high added value and stable wood grain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

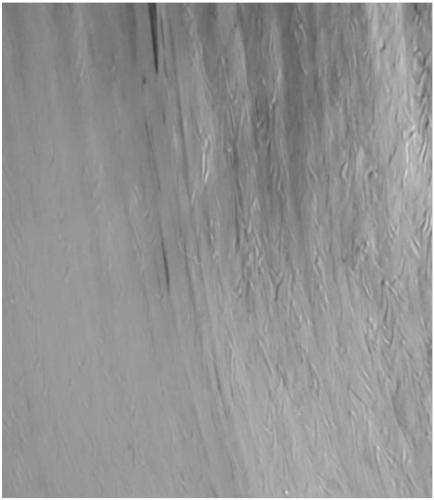

[0048] A kind of imitation wood grain huanghuali ASA alloy material, its preparation method is as follows:

[0049] 1) Preparation of wood grain base material:

[0050] Weigh each raw material: ASA resin 84%, polytetrafluoroethylene 5%, silicone masterbatch 5%, lubricant 1%, weathering agent 1%, K2270 yellow 0.5%, K1120FG yellow 1.4%, 600L carbon black 0.1%.

[0051] The raw materials are fully mixed in a high-speed mixing equipment, and then the mixture is placed in a twin-screw extruder SJ-35, extruded and granulated to obtain a wood grain base material. Among them, the host speed is 200rpm, the feeding speed is 12rpm, and the processing temperature is 180°C-210°C.

[0052] 2) Preparation of wood grain agent:

[0053] Weigh each raw material: ASA resin 63%, PCTG resin 10%, PCT resin 10%, polytetrafluoroethylene 3%, silicone masterbatch 3%, matting agent 1%, compatibilizer 5%, lubricant 2%, Weathering agent 1%, 600L carbon black 2%.

[0054] The raw materials are fully mixe...

Embodiment 2

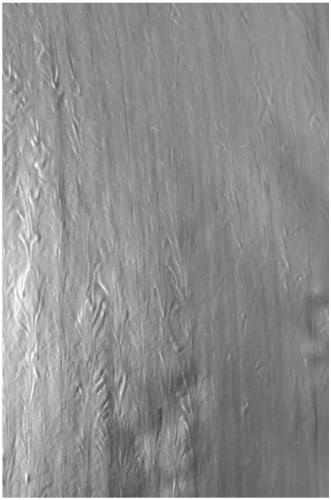

[0058] A kind of imitation wood grain red teak ASA alloy material, its preparation method is basically the same as embodiment 1, difference is:

[0059] 1) The raw materials of wood grain primer are: ASA resin 84%, PTFE 5%, silicone masterbatch 5%, lubricant 1%, weather resistance agent 1%, 4130 red 1.4%, K1120FG yellow 0.5%, 600L Carbon black 0.1%.

[0060] 2) The raw materials of wood grain agent are: ASA resin 58%, PCTG resin 15%, PCT resin 10%, polytetrafluoroethylene 3%, silicone masterbatch 3%, matting agent 1%, compatibilizer 5%, lubricating agent Agent 2%, weathering agent 1%, 600L carbon black 2%.

[0061] 80 parts of wood grain base materials and 20 parts of wood grain agent are added to the co-extrusion machine and extruded to obtain imitation wood grain red teak ASA plank board (such as figure 2 shown).

Embodiment 3

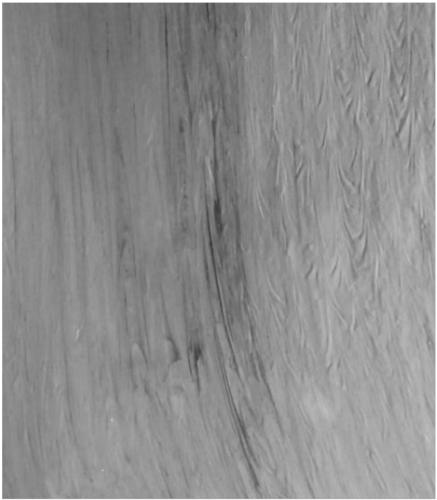

[0063] A kind of imitation wood grain huanghuali ASA alloy material (such as image 3 Shown), its preparation method is basically the same as Example 1, the difference is:

[0064] 2) The raw materials of wood grain agent are: ASA resin 53%, PCTG resin 20%, PCT resin 10%, polytetrafluoroethylene 3%, silicone masterbatch 3%, matting agent 1%, compatibilizer 5%, lubricating agent Agent 2%, weathering agent 1%, 600L carbon black 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com