Bioactive filler containing Brachybacterium nesterenkovii

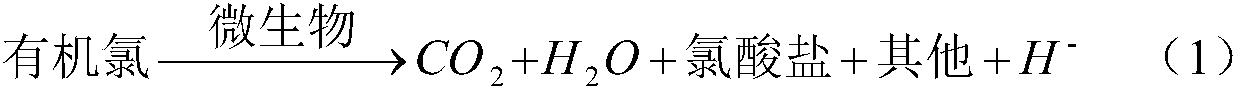

A technology based on the activity of Brevibacterium nissleri and microbial activity, which is applied in the field of bioactive fillers of Brevibacterium nissleri NY-1, can solve the problems of low treatment efficiency of volatile organic chlorine, uneven loading, and packing collapse, etc. Lightweight, shortened start-up period, and small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1 A microbial active filler for removing waste gas containing organic chlorine and its preparation

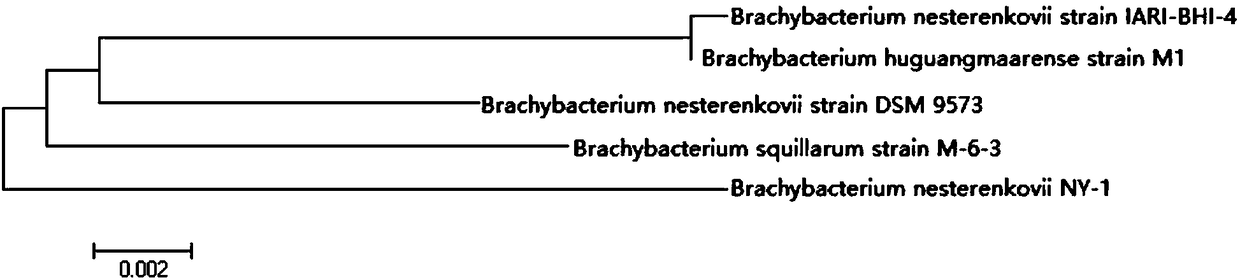

[0054] A kind of microbial active filler, described microbial active filler is prepared by the suspension of Brachybacterium nesterenkovii NY-1 bacterial suspension being adsorbed on the filler, and the filler is packed in the mesh surface hollow ball, can be better Purify waste gas containing organic chlorine.

[0055] The filler is volcanic rock; the density of the filler is 900kg / m 3 , the porosity is 55%, the particle size is 4mm; the mass ratio of the microbial suspension to the filler is 2:10; the concentration of Brevibacterium NY-1 in the microbial active filler is 2.5×10 7 CFU / g (填料) ;

[0056] The material of the hollow ball on the mesh surface is polyethylene; the hollow ball on the mesh surface has a diameter of 6 cm and is composed of two hemispheres, each hemisphere surface is porous, and the aperture of each hole is 2 mm; There is a lock on the...

Embodiment 2

[0070] Example 2 A microbial filler for removing waste gas containing organic chlorine and its preparation

[0071]A kind of microbial active filler, described microbial active filler is prepared by the suspension of Brachybacterium nesterenkovii NY-1 bacterial suspension being adsorbed on the filler, and the filler is packed in the mesh surface hollow ball, can be better Purify waste gas containing organic chlorine.

[0072] The filler is a polyurethane foam block; the filler density is 20kg / m 3 , the porosity is 90%, the particle size is 85mm; the mass ratio of the microbial suspension to the filler is 90:10; the concentration of Brevibacterium NY-1 in the microbial active filler is 1.0×10 10 CFU / g (填料) ;

[0073] The material of the hollow ball on the mesh surface is polypropylene; the hollow ball on the mesh surface has a diameter of 6 cm and is composed of two hemispheres, each hemisphere has a porous surface, and the aperture of each hole is 8 mm; There is a lock on ...

Embodiment 3

[0087] Example 3 A microbial filler for removing waste gas containing organic chlorine and its preparation

[0088] A kind of microbial active filler, described microbial active filler is prepared by the suspension of Brachybacterium nesterenkovii NY-1 bacterial suspension being adsorbed on the filler, and the filler is packed in the mesh surface hollow ball, can be better Purify waste gas containing organic chlorine.

[0089] The filler is molecular sieve; the filler density is 500kg / m 3 , the porosity is 75%, the particle size is 50mm; the mass ratio of the microbial suspension to the filler is 50:10; the concentration of Brevibacterium NY-1 in the microbial active filler is 6.0×10 8 CFU / g (填料) ;

[0090] The material of the hollow ball on the mesh surface is polyvinyl chloride; the hollow ball on the mesh surface has a diameter of 6cm and is composed of two hemispheres, each hemisphere has a porous surface, and the aperture of each hole is 5mm; The ring features a clasp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com