A catalytic cracking catalyst

A catalytic cracking and catalyst technology, used in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of low conversion rate of heavy oil and low zeolite cracking activity, and achieve high cracking activity of heavy oil, high crystallinity, coke selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0052] In the preparation method of catalytic cracking catalyst provided by the present invention, in the preparation method of phosphorus-containing and rare earth modified Y-type molecular sieve, in step (4), the gas-phase ultrastable modified Y-type molecular sieve obtained in step (3) is mixed with acid solution Contact to react (the present invention is called channel cleaning modification, referred to as channel cleaning, or acid treatment modification). One embodiment, the reaction of the gas-phase ultra-stable modified Y-type molecular sieve obtained in step (3) in contact with the acid solution is to react the gas-phase ultra-stable modified molecular sieve, that is, the gas-phase ultra-stable modified Y-type molecular sieve is mixed with acid solution, and reacts for a period of time, then the molecular sieve after reaction is separated from acid solution, such as through filtration and separation, and then through optional washing (washing is to remove residual Na in...

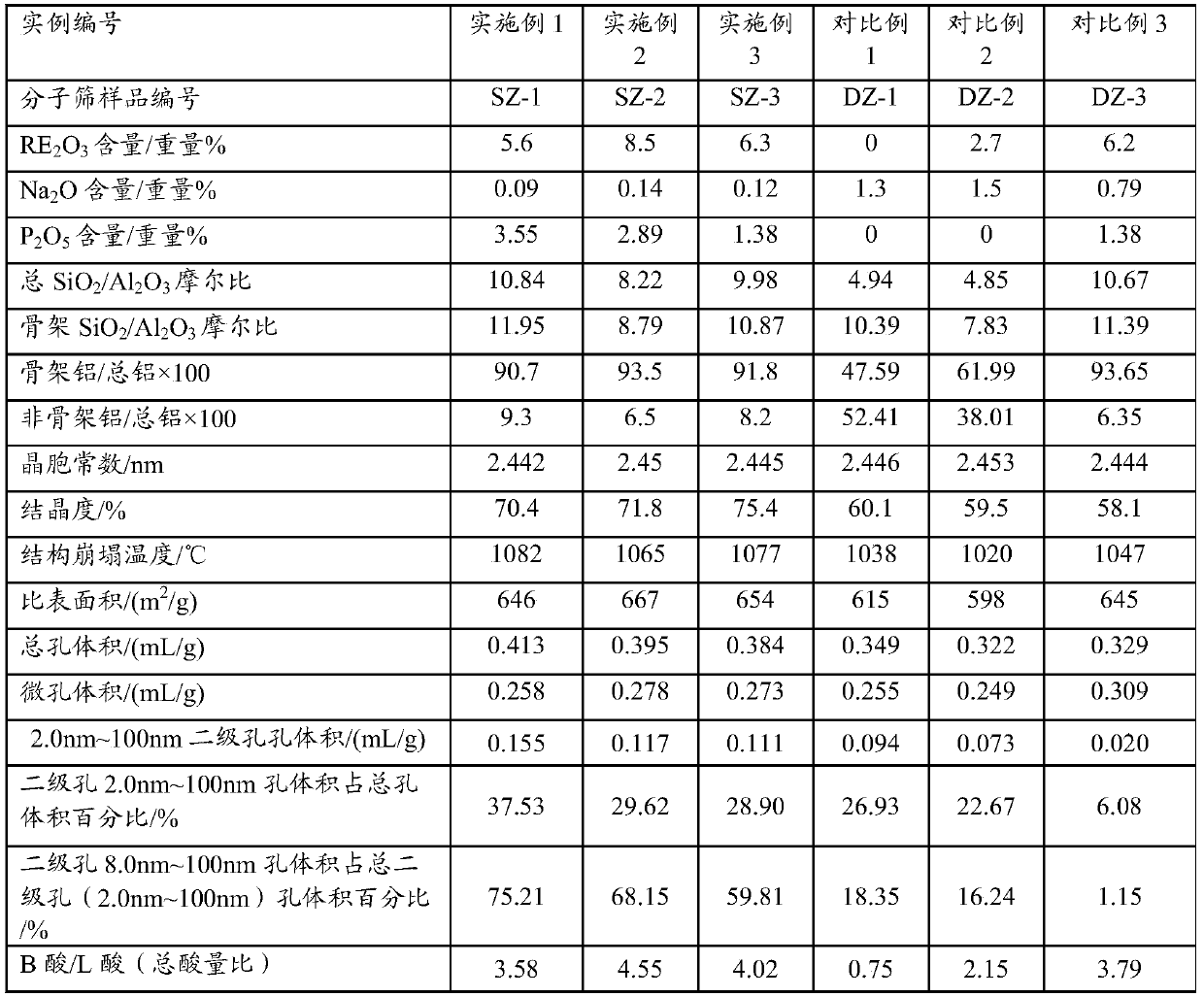

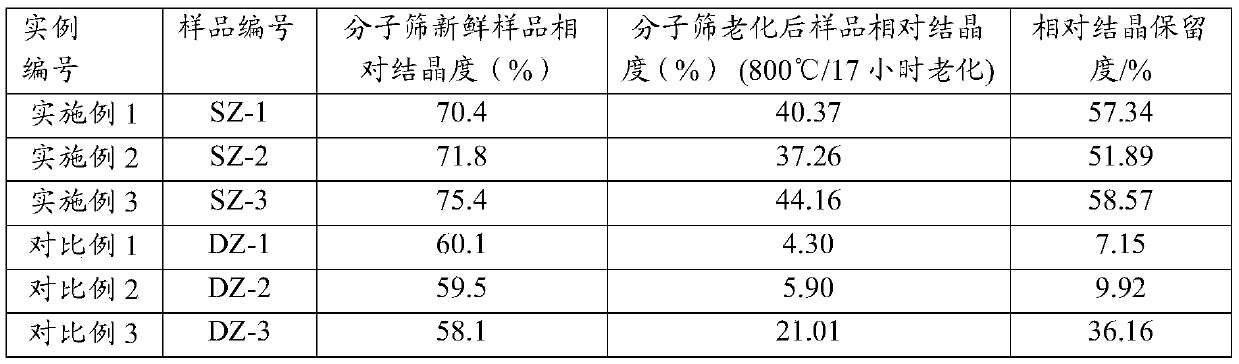

Embodiment 1

[0070] 2000Kg (dry basis weight) skeleton SiO 2 / Al 2 o 3 Be 4.6 NaY type zeolite (sodium oxide content 13.5% by weight, Sinopec Catalyst Qilu Branch Company produces) joins and is equipped with 20m 3 In the water exchange tank, stir well at 25°C and then add 600L RECl 3 Solution (RECl 3 The rare earth concentration in the solution is expressed as RE 2 o 3 Calculated as 319g / L), after stirring for 60 minutes, filter, wash, and the filter cake is continuously sent to a flash drying oven for drying; obtain a Y-type molecular sieve with a rare earth-containing conventional unit cell size with reduced sodium oxide content, and its sodium oxide content It is 7.0% by weight, and the unit cell constant is 2.471nm. Then, it is sent into a roasting furnace for modification: control the material atmosphere temperature at 390° C., and roast for 6 hours under 50% water vapor (containing 50 volume % water vapor in the atmosphere); then, The molecular sieve material is introduced into...

Embodiment 2

[0075] 2000Kg (dry basis weight) skeleton SiO 2 / Al 2 o 3 Be 4.6 NaY type zeolite (sodium oxide content 13.5% by weight, Sinopec Catalyst Qilu Branch Company produces) joins and is equipped with 20m3 In the primary exchange tank of decationized water, at 90°C, stir well and then add 800L RECl 3 Solution (RECl 3 The rare earth concentration in the solution is expressed as RE 2 o 3 Calculated as 319g / L), stirred for 60 minutes; filtered, washed, and the filter cake was sent to a flash drying oven for drying to obtain a Y-type molecular sieve with a rare earth-containing conventional unit cell size with a reduced sodium oxide content, and its sodium oxide content was 5.5 % by weight, the unit cell constant is 2.471nm; then, it is sent into a roasting furnace, and roasted for 5.5 hours at a temperature (atmosphere temperature) of 450°C and an 80% water vapor atmosphere; then, the molecular sieve material enters the roasting furnace for roasting and drying treatment, and the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com