Full-automatic polishing machine

A polishing machine, fully automatic technology, applied in the field of polishing machines, can solve the problems of poor polishing effect and low efficiency, and achieve the effect of comprehensive polishing, good polishing effect and good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

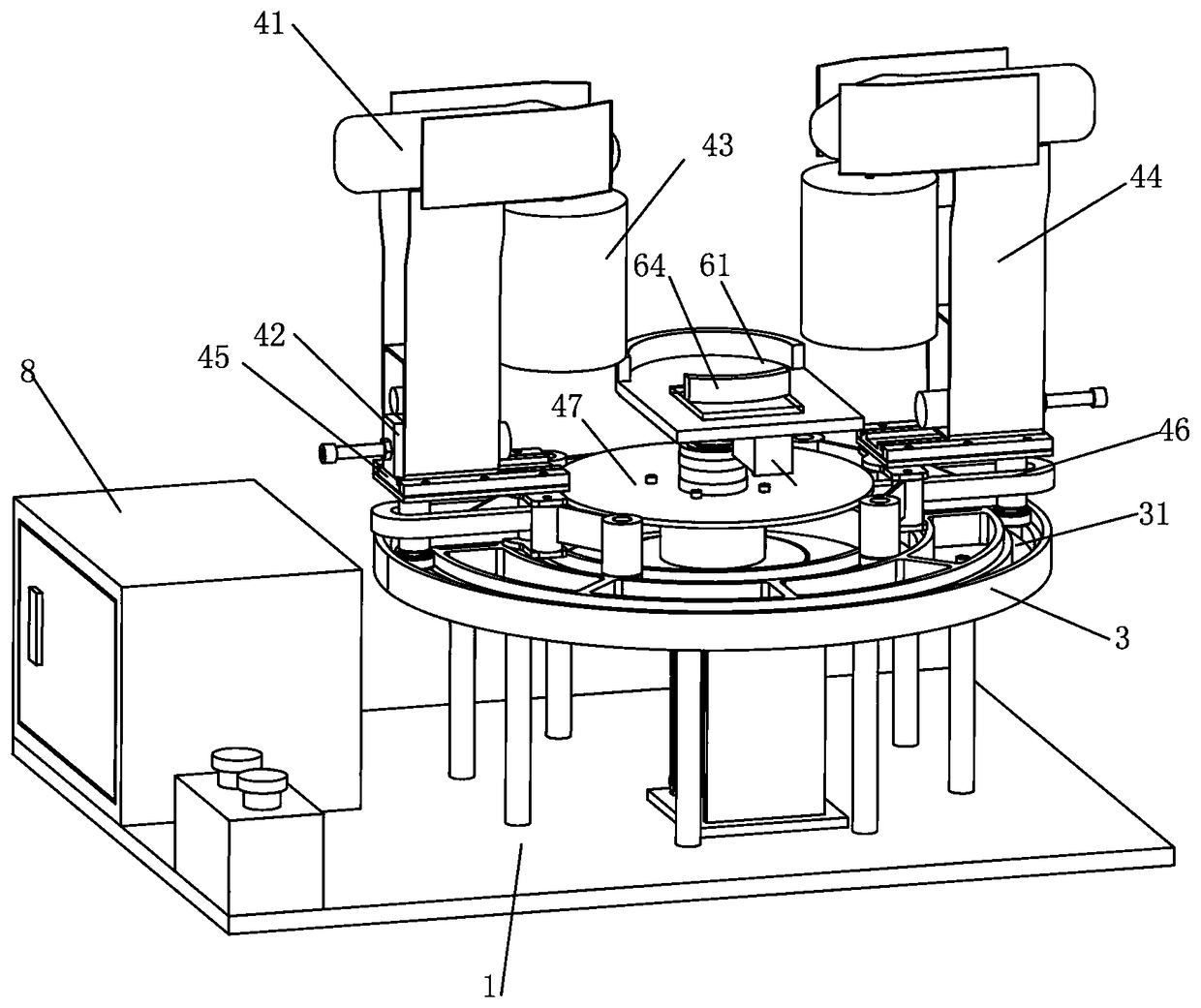

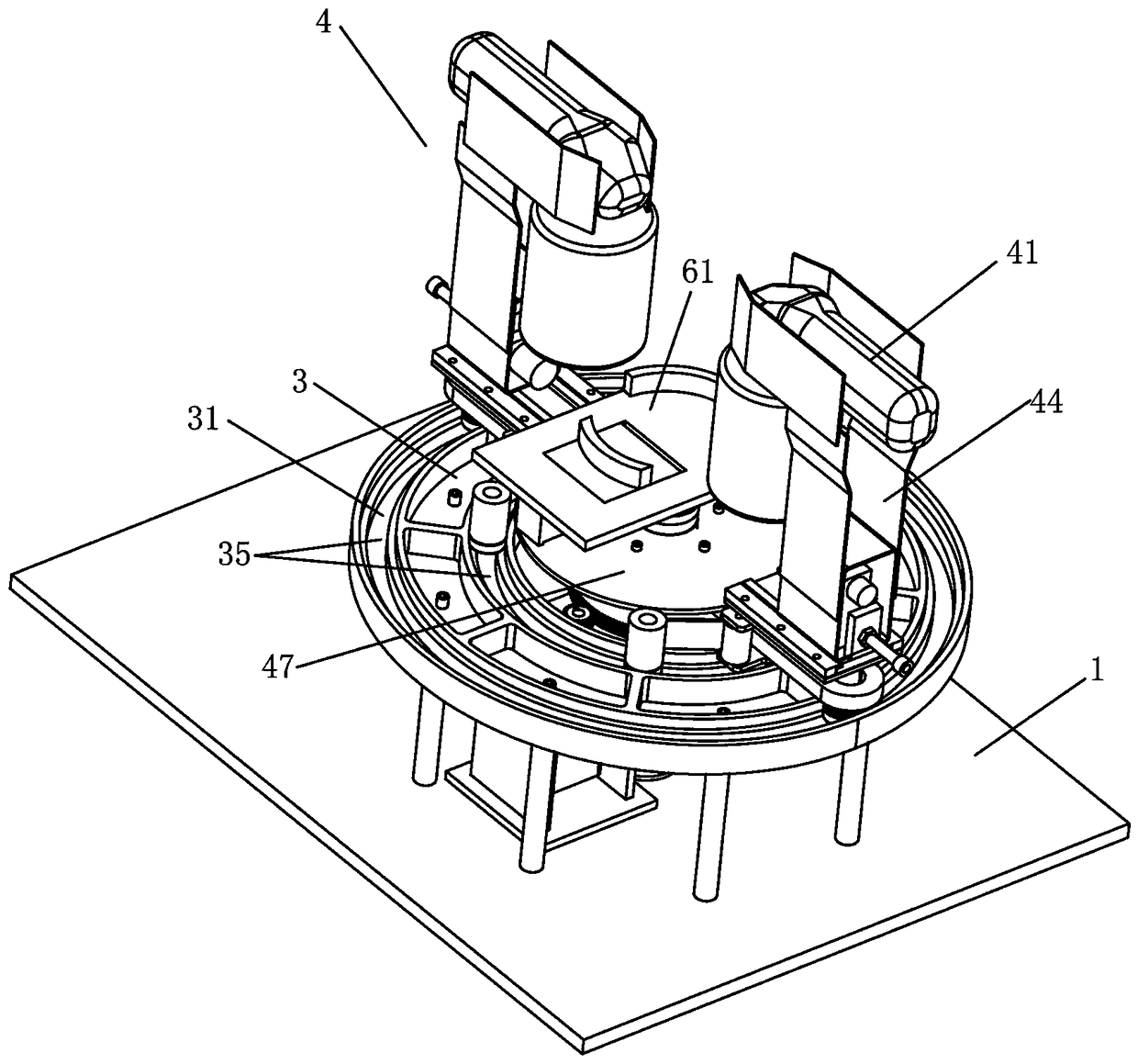

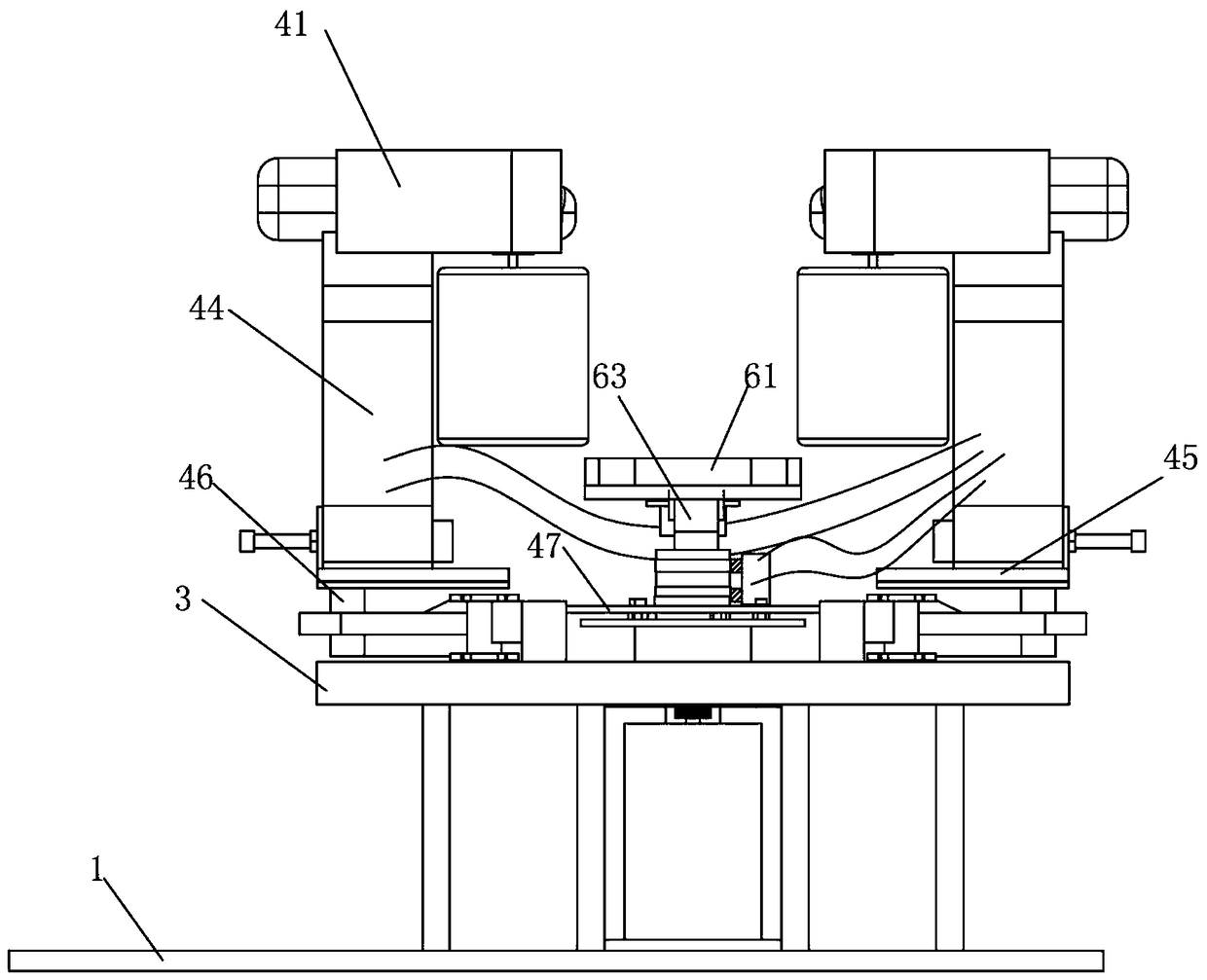

[0032] see Figure 1 to Figure 8 Shown, a kind of full-automatic polishing machine comprises control device 8, air pump 9, rotating motor 2, workbench 1 and guide rail disc 3, and described guide rail disc 3 is arranged on the workbench 1, and described guide rail disc 3 is provided with There is a grinding mechanism 4, and the guide rail disk 3 is provided with an annular guide rail 35 along its circumference, and the center of the guide rail disk 3 is provided with a relief hole 33.

[0033] Described grinding mechanism 4 comprises motor frame 44, grinding motor 41, grinding roller 43, grinding cotton, slide block 45, solenoid valve 42, back-moving spring 491 and swivel seat 46, and described swivel seat 46 is provided with slide rail 461, so The slide block 45 is arranged on the slide rail 461 along the radial slide of the guide rail disk 3, the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com