Crude oil pour point depressant and preparation method and application thereof

A technology of crude oil point depressant and point depressant, which is applied in chemical instruments and methods, mechanical equipment, gas/liquid distribution and storage, etc. The effect can not be satisfied and other problems, to achieve the effect of convenient large-scale production, good pour point depressing effect, and the freezing point of crude oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Weigh 300g of undecyl acrylate, 300g of phenyl acrylate, and 100g of vinyl acetate into a reactor, add 500mL of DMF to dissolve, slowly add 0.8g of BPO and 20mL of petroleum ether mixture dropwise with a dropping funnel, and heat at 85°C for 2 hours , after the reaction is completed, the product is obtained, that is, undecyl acrylate-phenyl acrylate-vinyl acetate copolymer solution, that is, the finished product of pour point depressant 1.

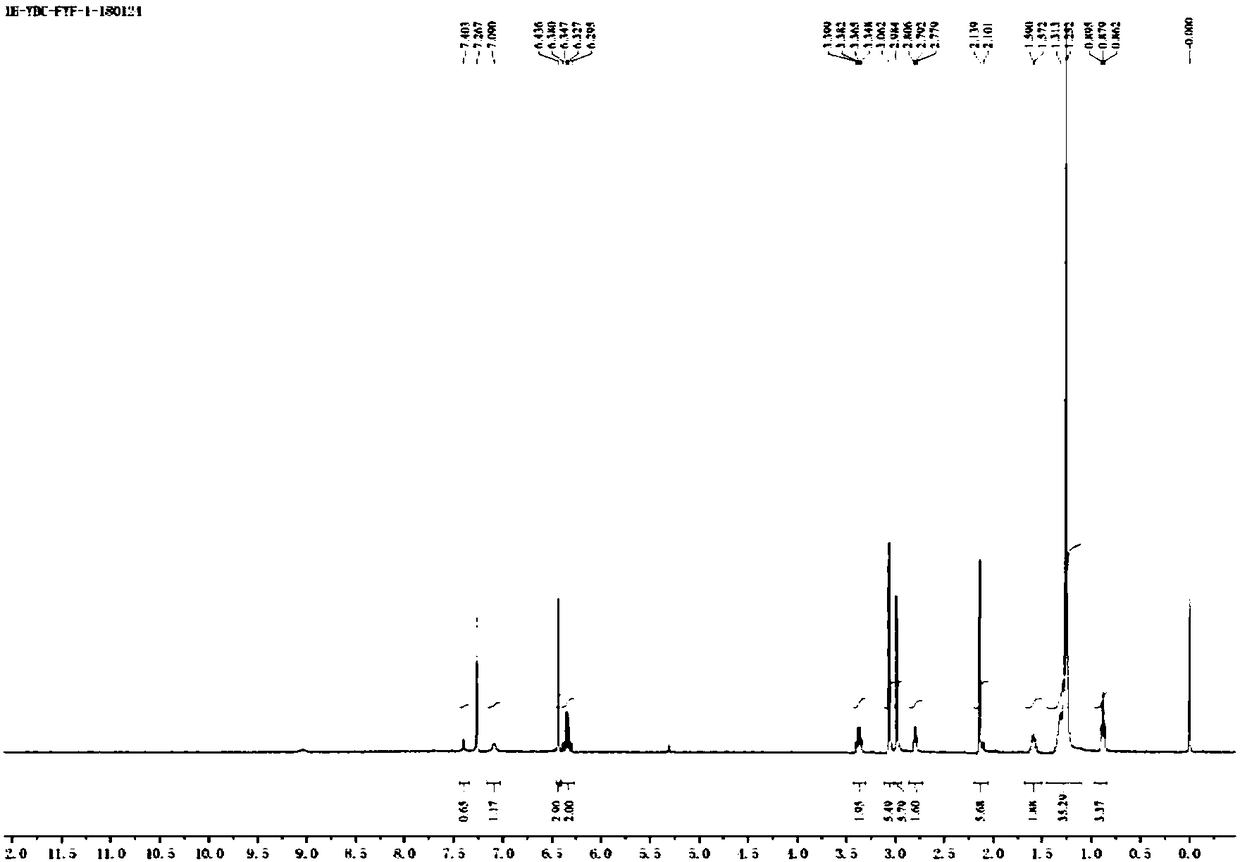

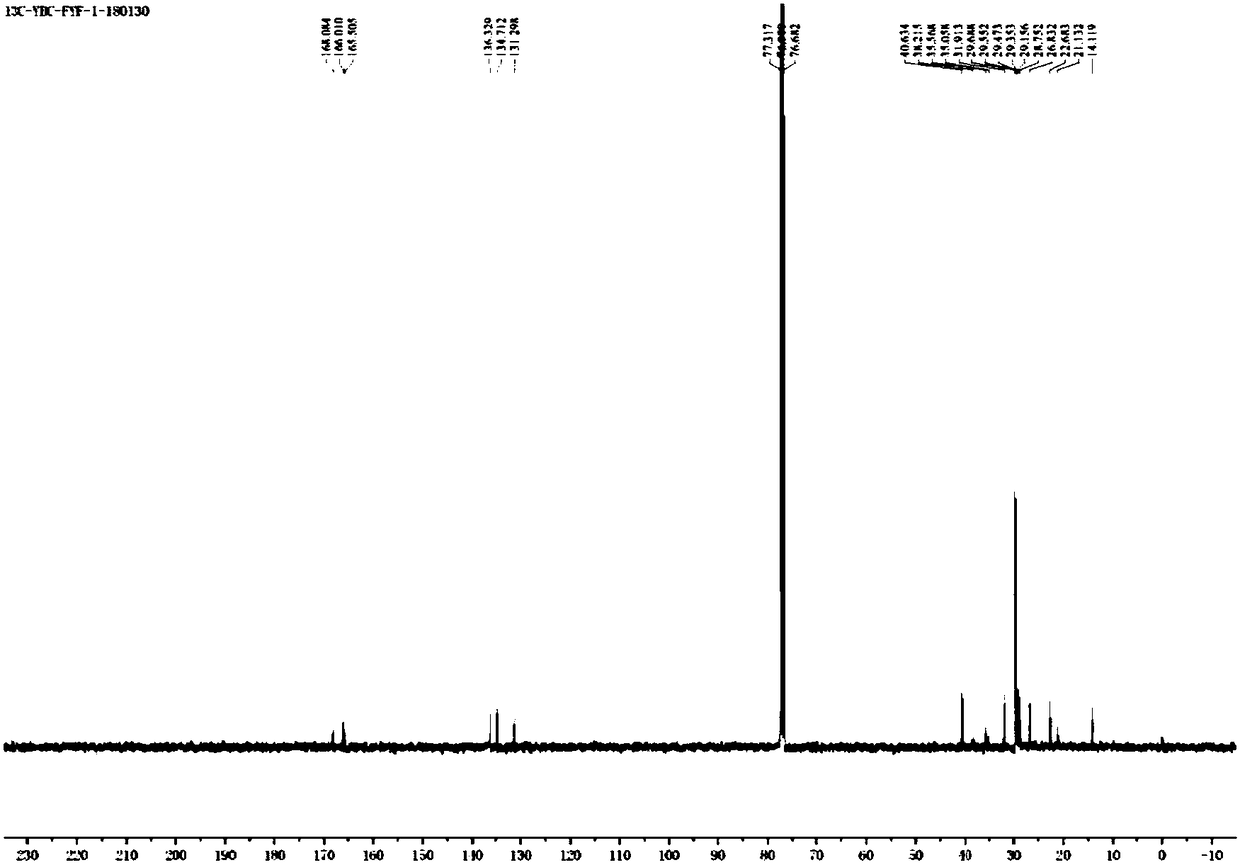

[0054] The proton nuclear magnetic resonance spectrum and the carbon nuclear magnetic resonance spectrum of the undecyl acrylate-phenyl acrylate-vinyl acetate copolymer solution that the present embodiment obtains are as follows: figure 1 , figure 2 shown.

[0055] Depression performance test:

[0056] Take 4 dry and clean test tubes and label them, add 10mL petroleum to the blank group. Take 0.005g of undecyl acrylate-phenyl acrylate-vinyl acetate copolymer solution in the remaining 3 tubes respectively, and add 10mL of crude o...

Embodiment 2

[0060] Weigh 300g of tridecyl acrylate, 300g of phenyl acrylate, and 100g of vinyl acetate into the reactor, add 500mL of DMF to dissolve, slowly add 0.8g of BPO and 20mL of petroleum ether mixture dropwise with a dropping funnel, and heat at 85°C for 2 hours After the reaction is completed, the product is obtained, namely tridecyl acrylate-phenyl acrylate-vinyl acetate copolymer solution, which is the finished product of pour point depressant 2.

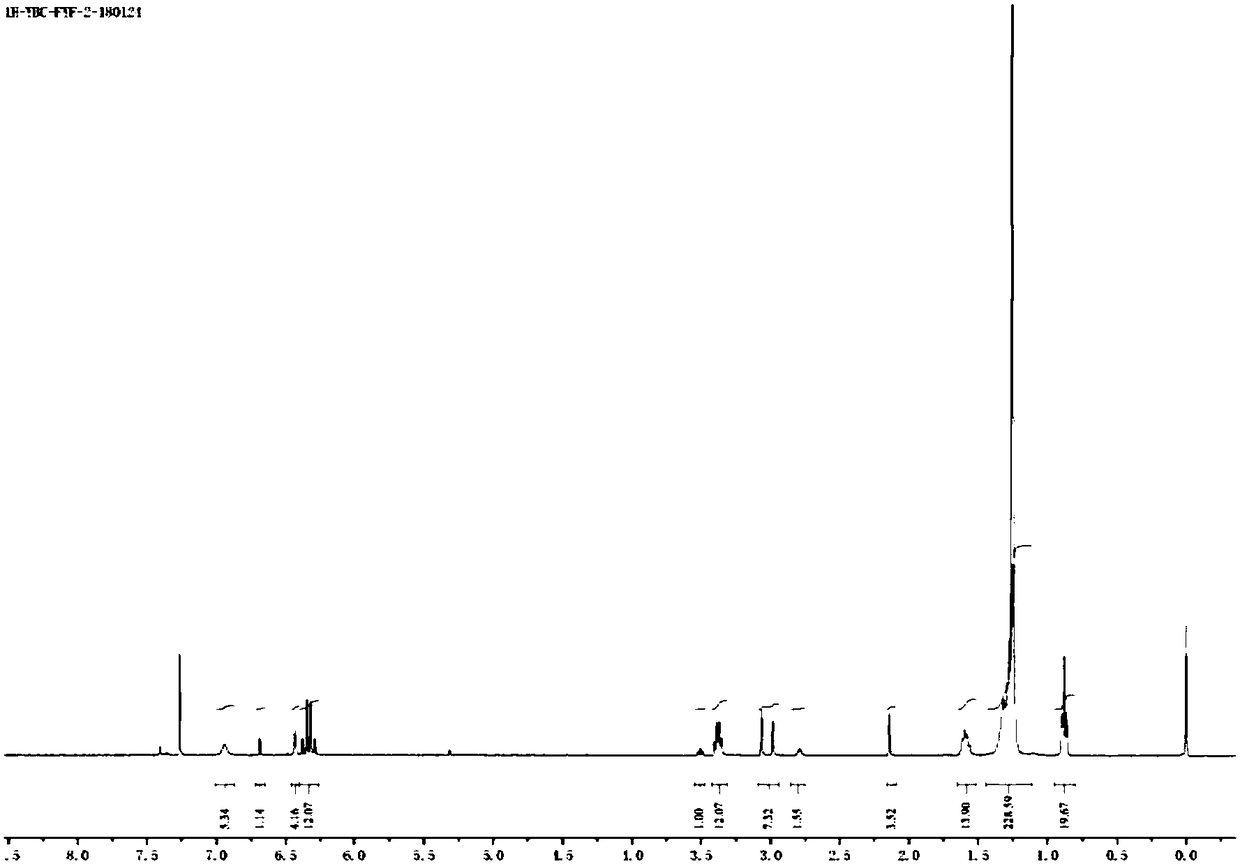

[0061] The proton nuclear magnetic resonance spectrum and the carbon nuclear magnetic resonance spectrum of the tridecyl acrylate-phenyl acrylate-vinyl acetate copolymer solution that the present embodiment obtains are as follows: image 3 , Figure 4 shown.

[0062] Depression performance test:

[0063] Take 4 dry and clean test tubes and label them, add 10mL petroleum to the blank group. Take 0.005g of undecyl acrylate-phenyl acrylate-vinyl acetate copolymer solution in the remaining 3 tubes respectively, and add 10mL of crude ...

Embodiment 3

[0067] Weigh 300g of pentadecyl acrylate, 300g of phenyl acrylate, and 100g of vinyl acetate into the reactor, add 500mL of DMF to dissolve, slowly add 0.8g of BPO and 20mL of petroleum ether mixture dropwise with a dropping funnel, and heat at 85°C for 2 hours After the reaction is completed, the product is obtained, namely pentadecyl acrylate-phenyl acrylate-vinyl acetate copolymer solution, which is the finished product of pour point depressant 3.

[0068] The proton nuclear magnetic resonance spectrum and the carbon nuclear magnetic resonance spectrum of the pentadecyl acrylate-phenyl acrylate-vinyl acetate copolymer solution that the present embodiment obtains are as follows: Figure 5 , Figure 6 shown.

[0069] Depression performance test:

[0070] Take 4 dry and clean test tubes and label them, add 10mL petroleum to the blank group. Take 0.005g of pentadecyl acrylate-phenyl acrylate-vinyl acetate copolymer solution in the remaining 3 tubes respectively, and add 10mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com