Deposition chamber and film deposition device

A deposition cavity and cavity technology, which is applied in the field of magnetron sputtering, can solve the problems of instability and unevenness of the deposition process, and achieve the effects of overcoming the instability of the deposition process, improving the stability and overcoming the unevenness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

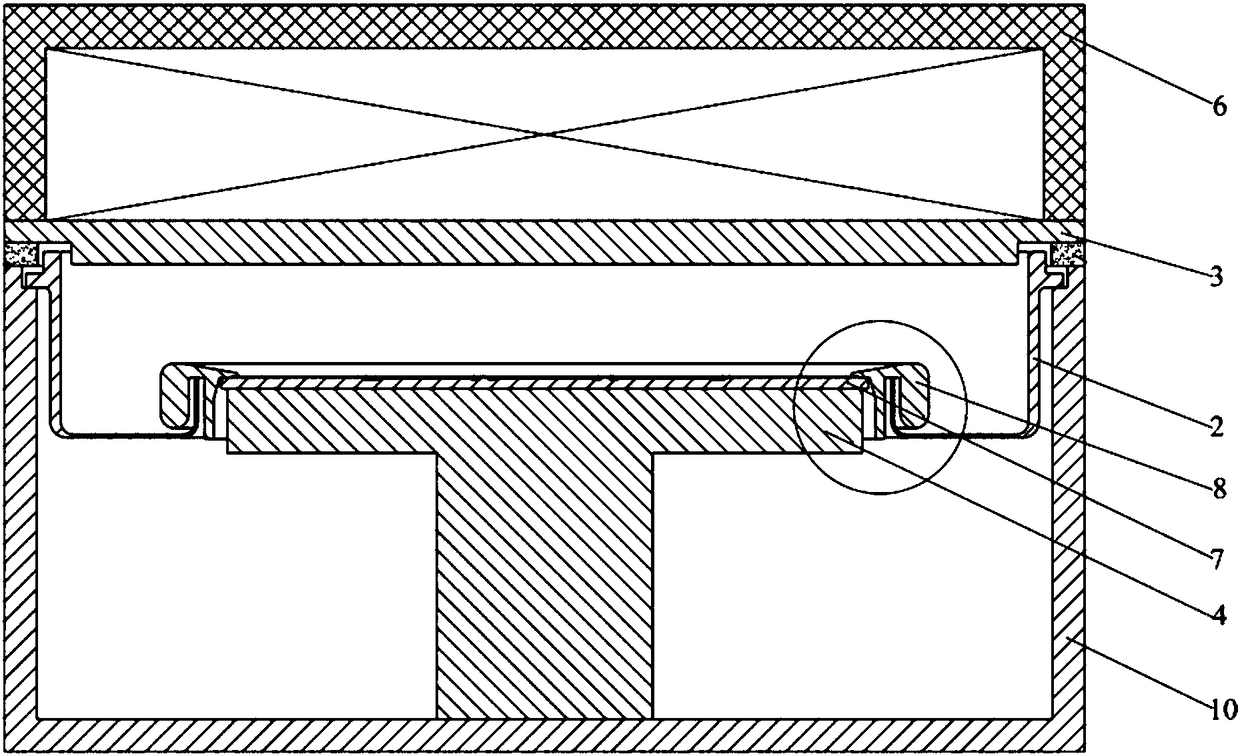

[0036] This embodiment provides a deposition chamber, such as Figure 4 and Figure 5 As shown, it includes a cavity 1, a liner 2 surrounding the side wall of the cavity 1, a target 3 and a base 4, the target 3 is set above the top opening of the liner 2, and the base 4 is set on the liner 2 The lower part of the bottom opening also includes a shielding member 5 , which is fixedly arranged around the periphery of the base 4 , and the orthographic projection of the shielding member 5 on the target 3 covers the bottom of the inner liner 2 .

[0037] Wherein, the process of depositing thin films on the substrate in the deposition chamber is carried out in the lining 2 . Before the process starts, the susceptor 4 moves towards the target 3 so as to abut against the bottom of the inner liner 2, thereby forming a relatively closed plasma process area. The orthographic projection of the shield 5 on the target 3 covers the bottom of the inner liner 2. During the deposition process, ...

Embodiment 2

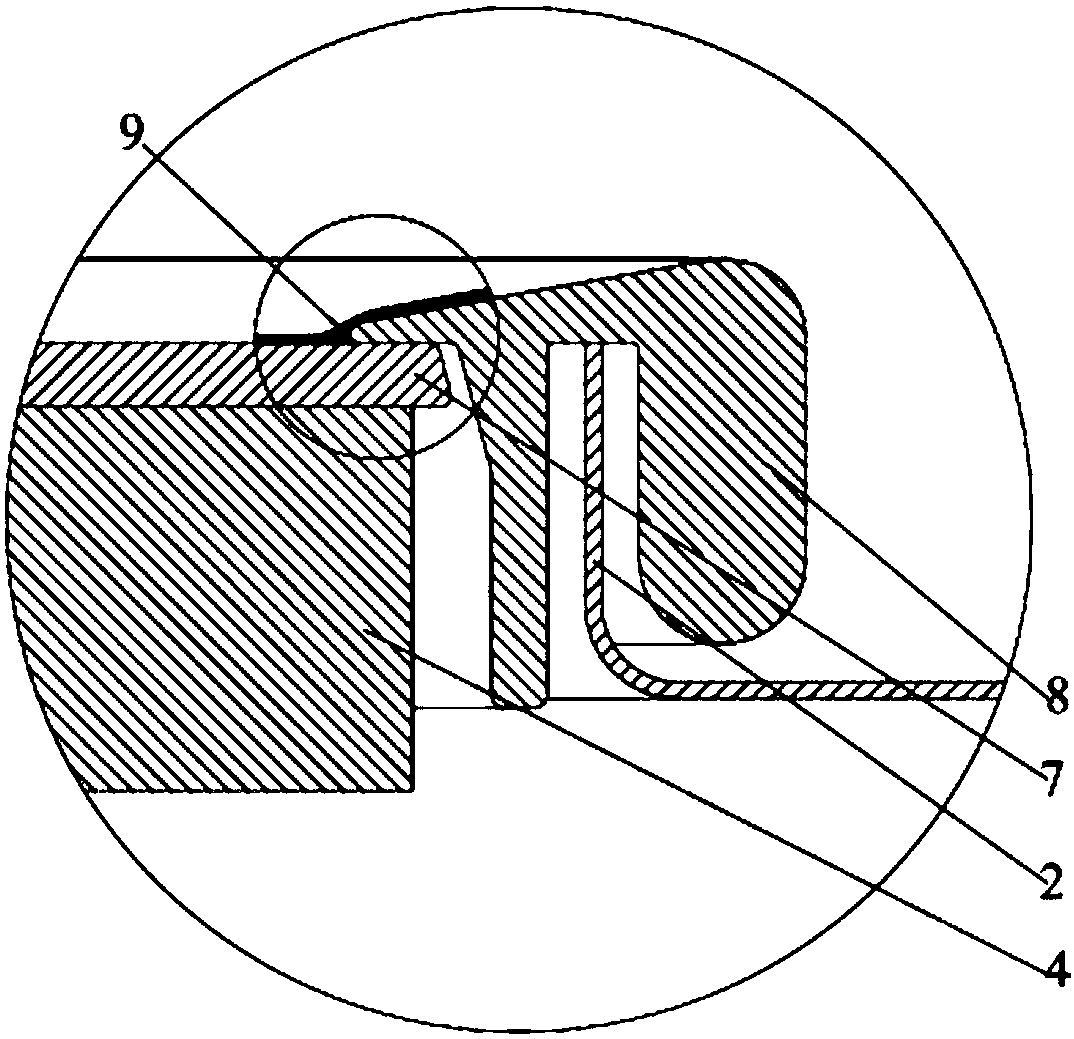

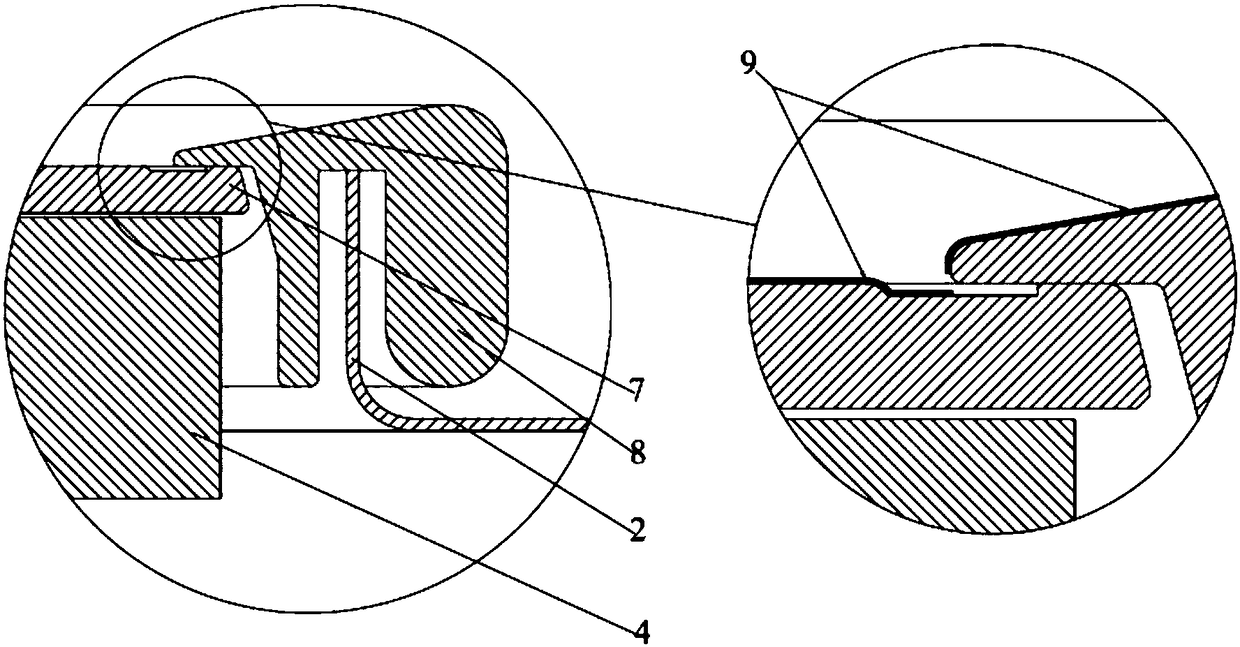

[0048] This embodiment provides a deposition chamber, which is different from Embodiment 1, as Figure 6 As shown, the shutter 5 includes an annular plane 51, a first cylindrical structure 52 and a second cylindrical structure 53, wherein one end of the first cylindrical structure 52 is connected to the outer periphery of the annular plane 51; The first end is connected to the inner periphery of the annular plane 51 , and the second end is fixed to the bottom surface of the carrier 41 .

[0049] Wherein, the height of the second cylindrical structure 53 is smaller than the height of the first cylindrical structure 52 .

[0050] In this embodiment, the shielding member 5 is a rectangular groove; the rectangular groove is recessed away from the inner liner 2 . The side wall on one side of the rectangular groove is fixedly arranged on the bottom surface of the carrier 41, the other side wall of the rectangular groove is at least partly interlaced with the side wall of the inner ...

Embodiment 3

[0055] This embodiment provides a film deposition device, including the deposition chamber in any one of Embodiments 1-2.

[0056] By adopting the deposition chamber in any one of the embodiments 1-2, not only the film deposition quality of the film deposition device is improved, but also the stability of the film deposition process of the film deposition device is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com