Cofferdam construction method for deepwater hard rock back-cover-free steel plate pile

A back-sealing steel plate and construction method technology, applied in infrastructure engineering, construction, etc., can solve the problems of heavy workload, long construction period, difficult recycling, etc., and achieve the effect of avoiding equipment investment, improving construction efficiency, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

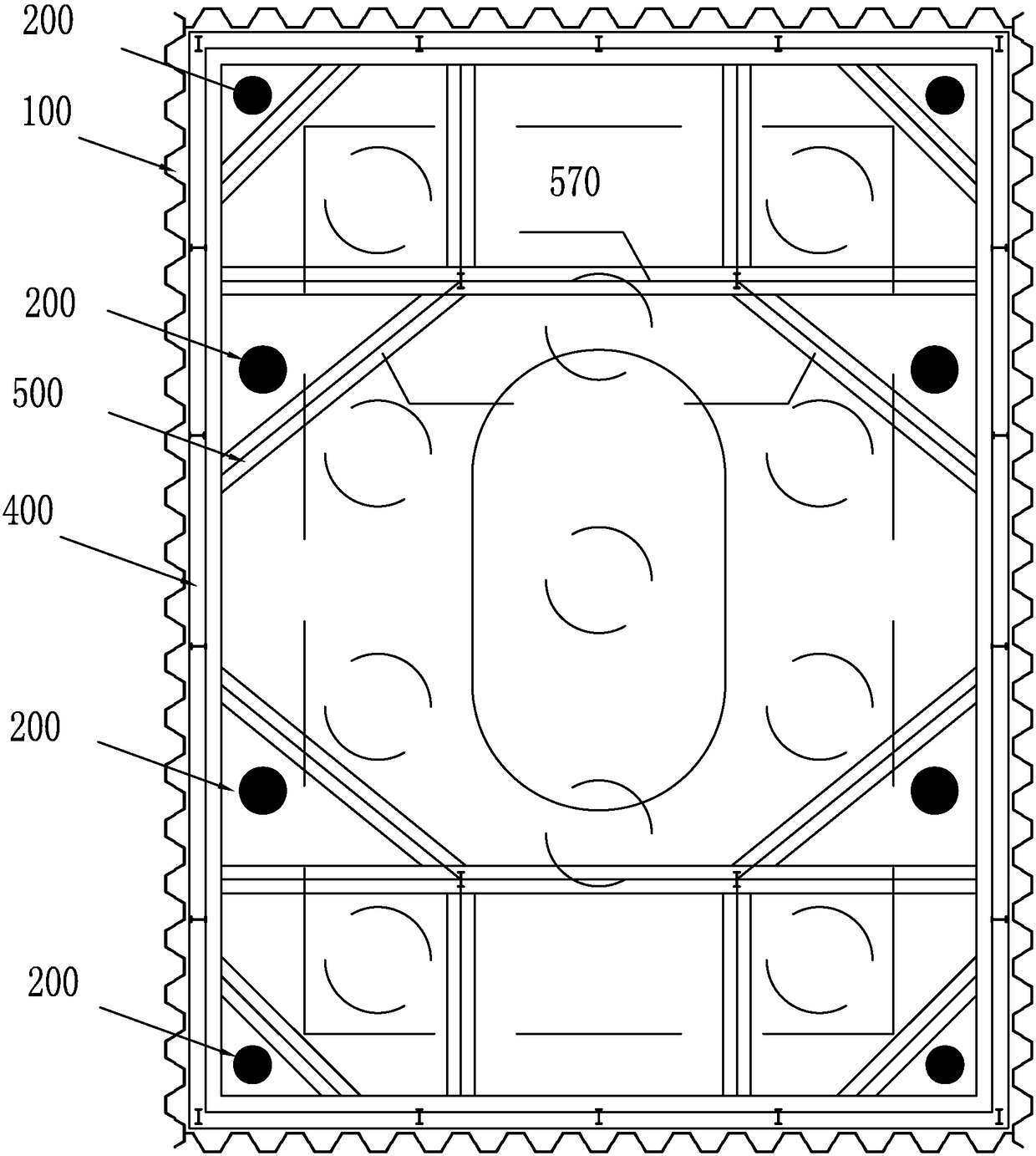

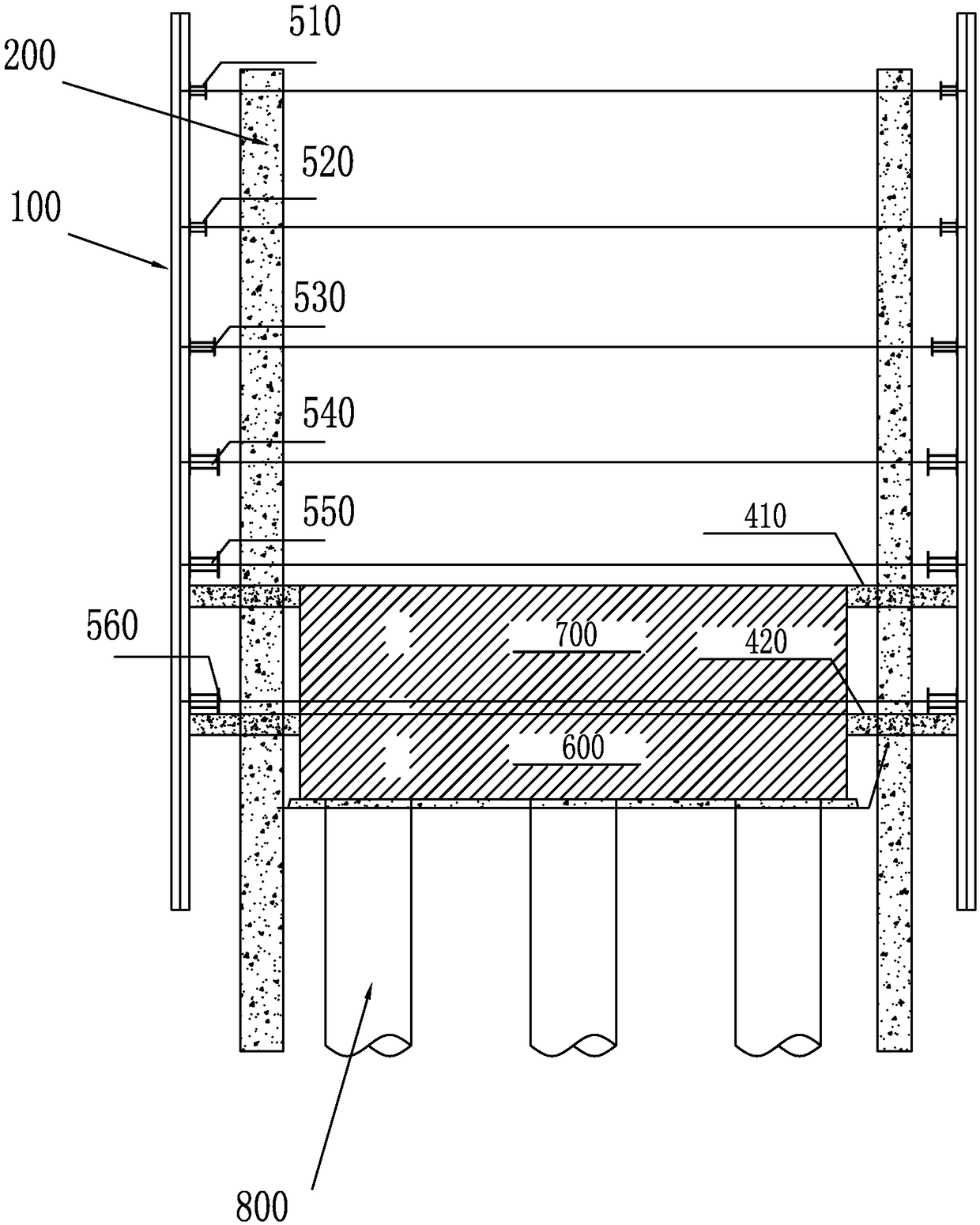

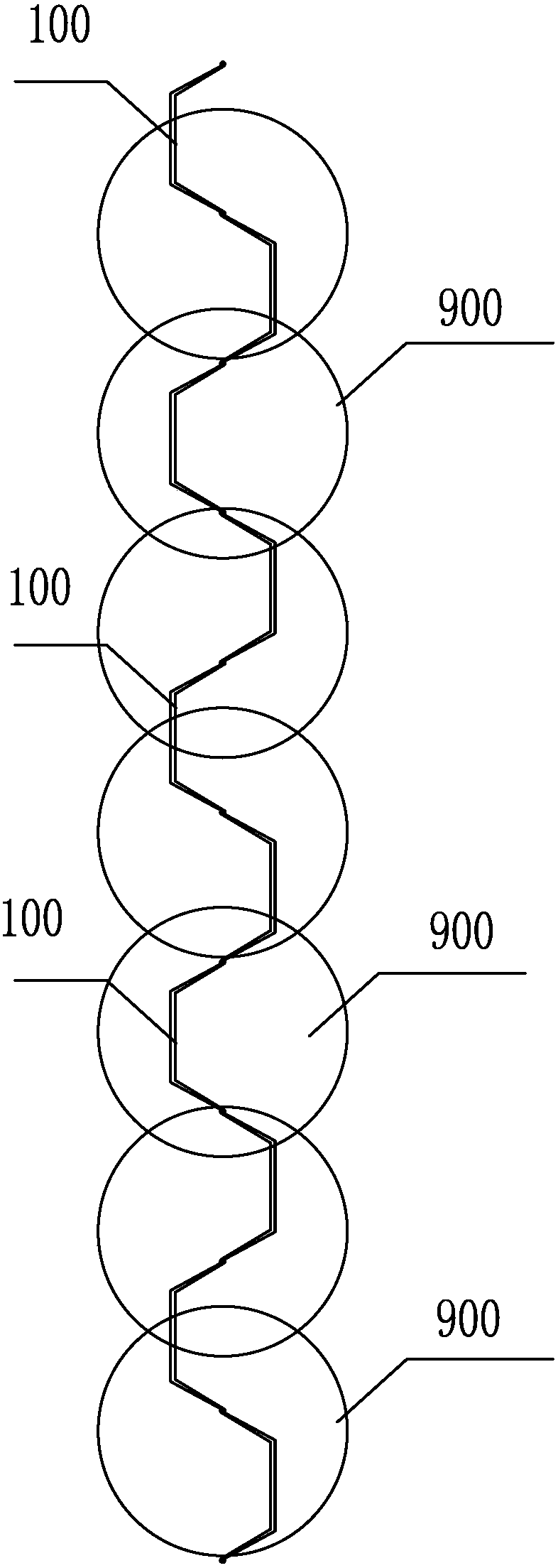

[0052] join Figure 1 to Figure 6 , while constructing the cap pile foundation on the drilling platform, carry out the construction of the stabilizing pile 200. The stabilization piles adopt 4 reinforced concrete piles of φ0.8m (located at the four corners of the cofferdam) and 4 pieces of φ1.0m (located in the middle of the long side of the cofferdam). 510) level, the bottom is located 6m below the bottom of the cap, and enters the moderately differentiated rock formation. The stabilizing pile is constructed by a percussion drill with a small drill bit, and a reinforcement cage is arranged inside. At the same time as the pile foundation construction, the pilot hole slotting operation can be carried out in different areas. The pilot hole is constructed by rotary drilling and jumping, see image 3 , That is, the notch is formed by superimposing the circular holes, first drilling into the No. 1 and No. 3 holes, and then constructing the No. 2 hole in the middle. The rotary d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com