Solid electrolyte ceramic material with symmetrical gradient pore structure and its preparation method and application

A technology of solid electrolyte and ceramic materials, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of large thickness of solid electrolyte layer, low lithium ion conductivity, and excessive internal resistance of batteries, so as to improve discharge capacity and Rate capability, increased deposition amount, small thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0049] Embodiment 1: The solid electrolyte ceramic material with a symmetrical gradient pore structure in this embodiment is Li 7- x La 3 Zr 2-x N x o 12 , Li 7 La 3 Zr 2 o 12 , Li 2 ATi 3 o 8 or Li 1+x m x Ti 2-x (PO 4 ) 3 ; where Li 7-x La 3 Zr 2-x N x o 12 where 0≤x≤1.2, N is Al, Ta, Ge or Nb; Li 2 ATi 3 o 8 In A is Zn, Mg or Co; Li 1+x m x Ti 2-x (PO 4 ) 3 where 0≤x≤0.5, M is Al, Ga, In or Sc;

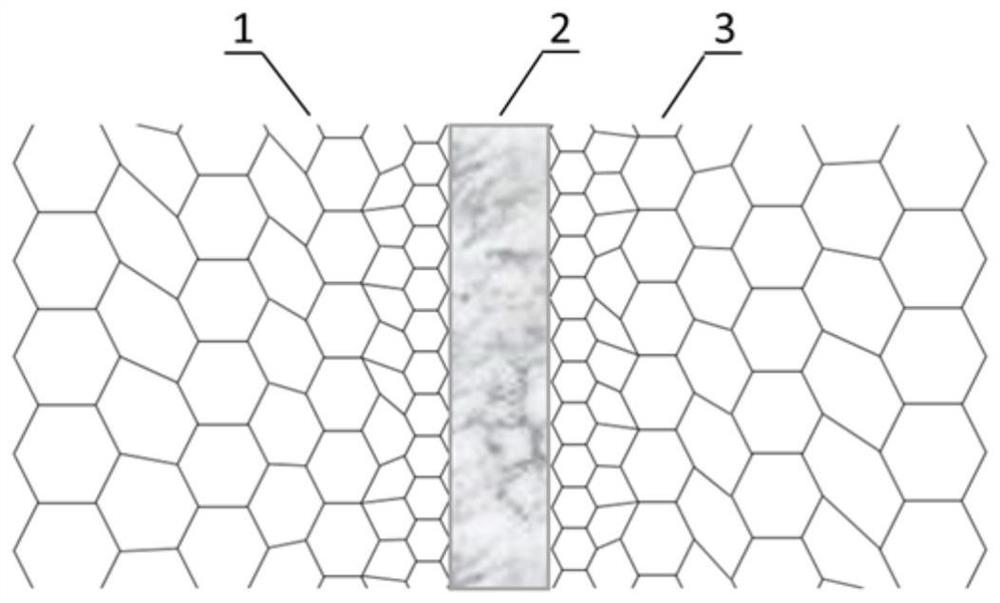

[0050] The solid electrolyte ceramic material includes a three-layer structure, with a dense layer in the middle and porous layers on both sides. The pore diameters of the porous layer are arranged in a gradient, and the pore diameters increase sequentially along the direction away from the dense layer, forming gradually changing gradient pores in the porous layer. structure.

[0051] In this embodiment, the solid electrolyte is etched with acids in different proportions to prepare a three-layer ceramic with a dense layer in the middle and porous layer...

specific Embodiment approach 2

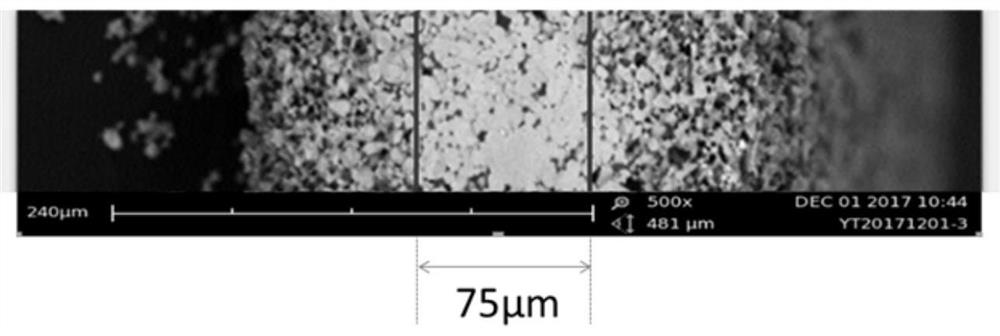

[0053] Embodiment 2: This embodiment is different from Embodiment 1 in that: the thickness of the dense layer is 10 μm-100 μm, and the thickness of the porous layer is 100 μm-400 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0054] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the density of the dense layer is greater than 90%. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com