Tile adhesive containing granite waste rock powder and preparation process thereof

A tile adhesive and waste rock powder technology, which is applied in the field of tile adhesive, can solve problems such as high production costs, achieve the effects of improving product performance, reducing production costs, and increasing tensile bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

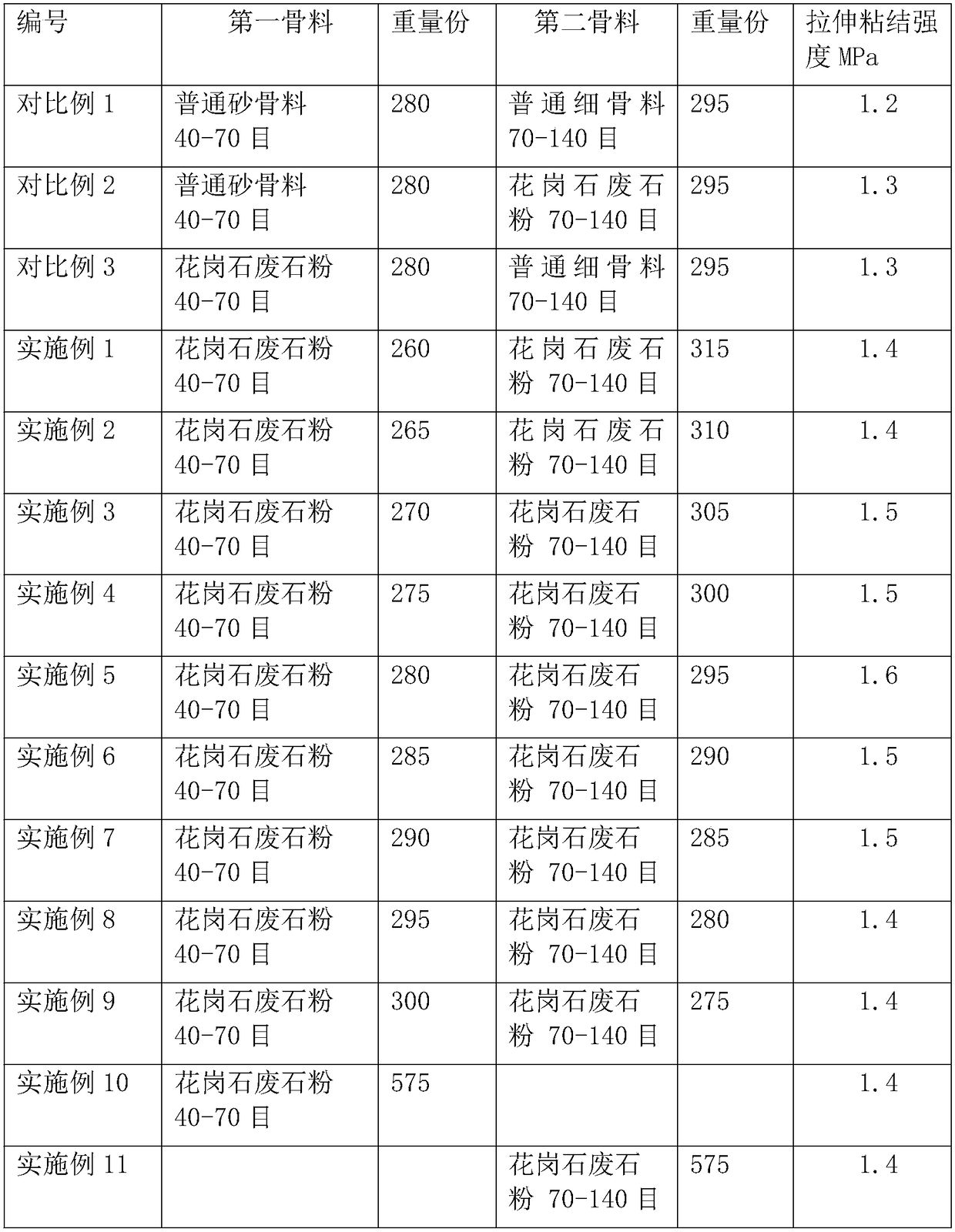

Examples

Embodiment 1

[0027] This embodiment relates to a tile adhesive containing granite waste rock powder and its preparation process. The tile adhesive is composed of the following raw materials in parts by weight: 260 wt. Parts: 315 parts by weight of fine granite waste rock powder with a fineness of 70 to 140 purposes, 15.4 parts by weight of dispersible rubber powder, 3 parts by weight of cellulose ether, and 0.6 parts by weight of starch ether; 6 parts by weight of calcium formate and 400 parts by weight of cement. Its preparation process is as follows:

[0028] (1) Take raw materials according to the parts by weight in Example 1;

[0029] (2) Place the weighed raw materials in a powder mixer and stir evenly;

[0030] (3) Mix the evenly stirred powder and water in a ratio of 3.5:1, and stir into a uniform paste;

[0031] (4) Let it stand for 8 minutes, let it fully ripen, and stir it again until the finished product.

Embodiment 2

[0033] This embodiment relates to a tile adhesive containing granite waste rock powder and its preparation process. The tile adhesive is composed of the following raw materials in parts by weight: 265 wt. Parts: 310 parts by weight of fine granite waste rock powder with a fineness of 70 to 140 purposes, 15.4 parts by weight of dispersible rubber powder, 3 parts by weight of cellulose ether, 0.6 parts by weight of starch ether; 6 parts by weight of calcium formate and 400 parts by weight of cement. Its preparation process is as follows:

[0034] (1) Take raw materials according to the parts by weight in Example 1;

[0035] (2) Place the weighed raw materials in a powder mixer and stir evenly;

[0036] (3) Mix the evenly stirred powder and water in a ratio of 3.5:1, and stir into a uniform paste;

[0037] (4) Let it stand for 8 minutes, let it fully ripen, and stir it again until the finished product.

Embodiment 3

[0039] This embodiment relates to a tile adhesive containing granite waste rock powder and its preparation process. The tile adhesive is composed of the following raw materials in parts by weight: 270 wt. Parts: 305 parts by weight of fine granite waste rock powder with a fineness of 70 to 140 purposes, 15.4 parts by weight of dispersible rubber powder, 3 parts by weight of cellulose ether, and 0.6 parts by weight of starch ether; 6 parts by weight of calcium formate and 400 parts by weight of cement. Its preparation process is as follows:

[0040] (1) Take raw materials according to the parts by weight in Example 1;

[0041] (2) Place the weighed raw materials in a powder mixer and stir evenly;

[0042] (3) Mix the evenly stirred powder and water in a ratio of 3.5:1, and stir into a uniform paste;

[0043] (4) Let it stand for 8 minutes, let it fully ripen, and stir it again until the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap