A kind of epitaxy device of semiconductor light-emitting diode

A technology of light-emitting diodes and semiconductors, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of a large increase in the thickness of the epitaxial structure, a large increase in the growth cost, and an increase in the operating voltage of the device, so that the conductivity can be easily regulated and improved. Current spreading and small increase in device voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

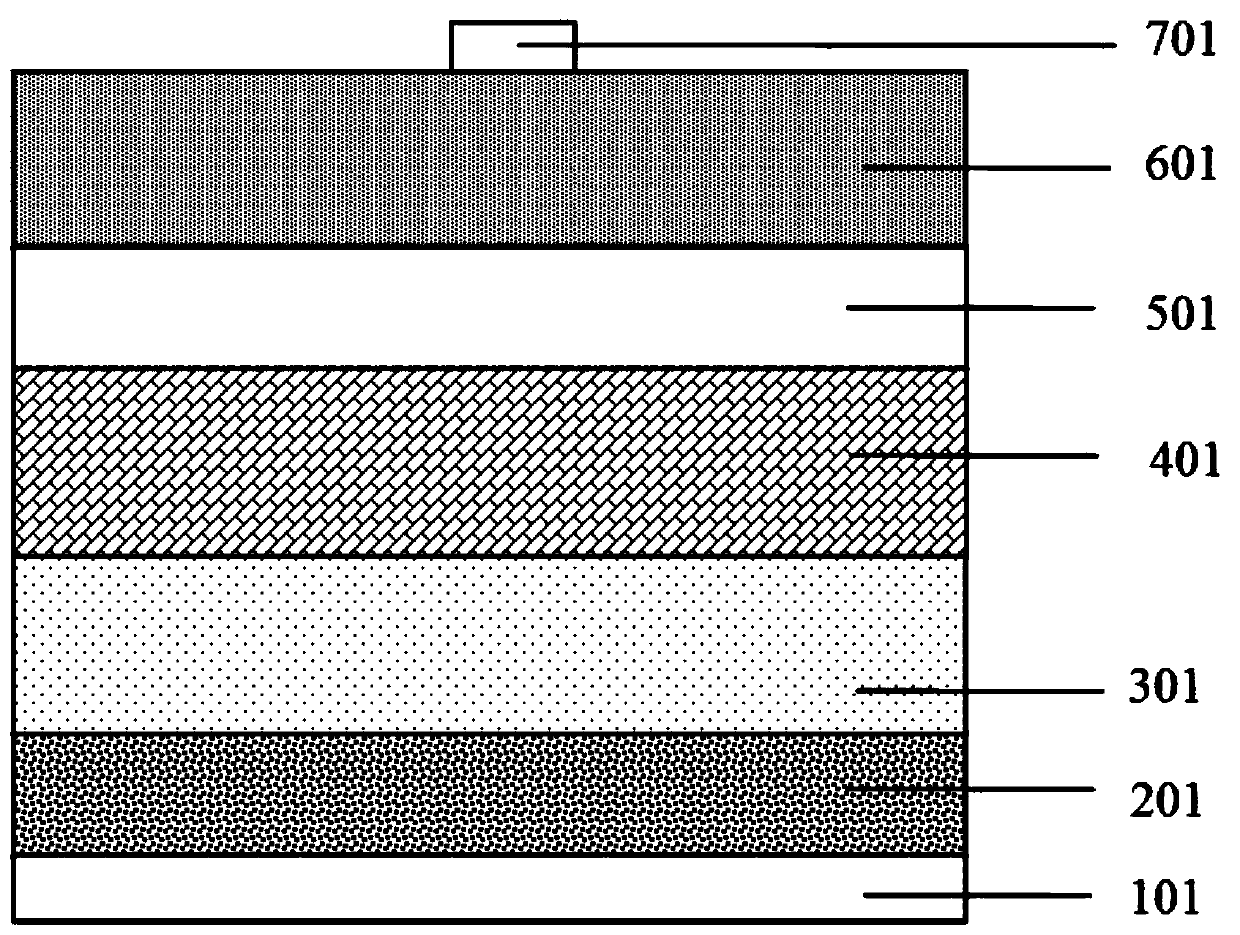

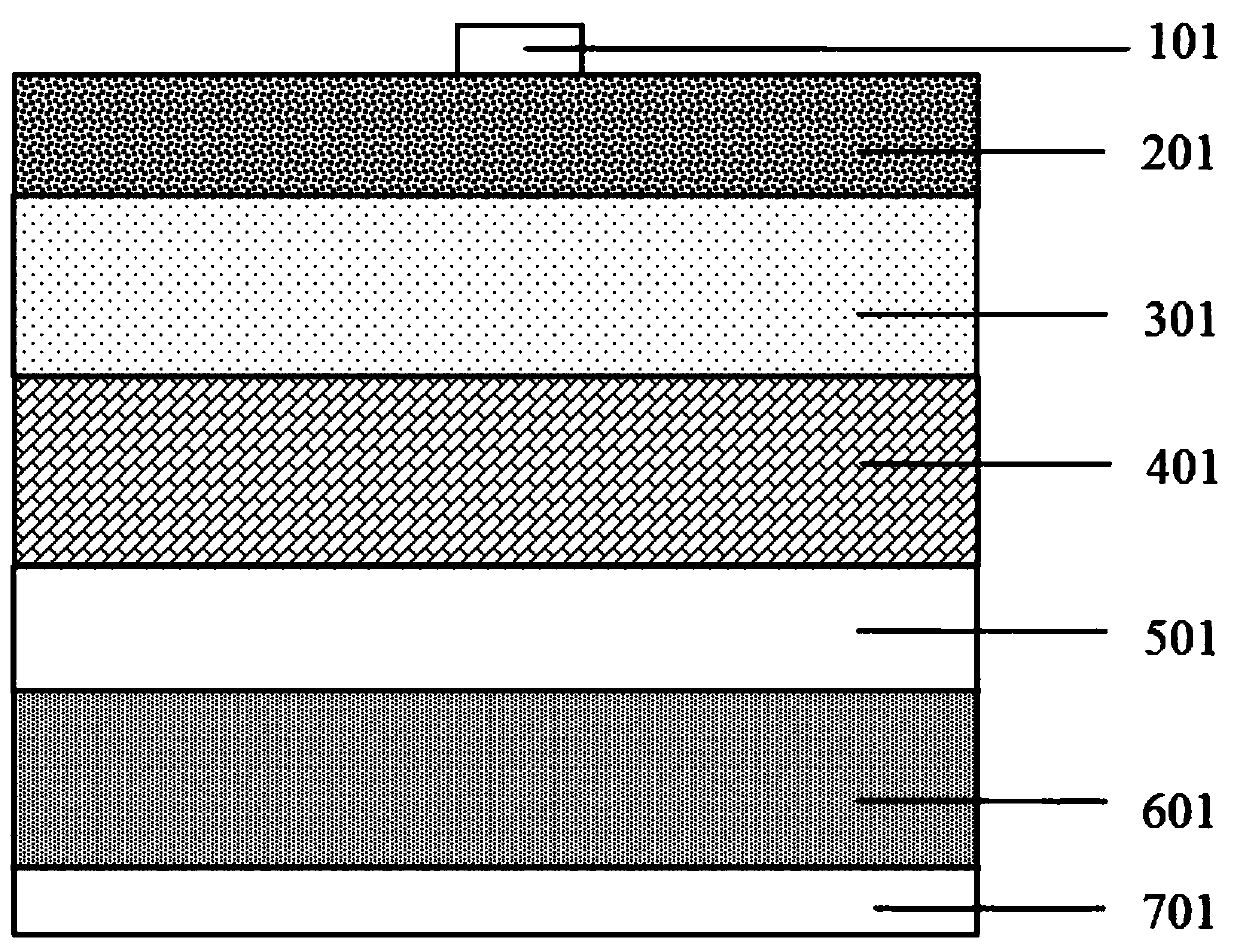

[0026] A kind of epitaxy device of semiconductor light-emitting diode of the present invention, as figure 1 As shown, it includes an N electrode 101, an N-type semiconductor contact layer 201 (in direct contact with the N electrode, used to adjust the contact resistance between the N electrode and the N-type semiconductor interface), an N-type semiconductor conductive layer 301, a light emitting layer 401, and a P-type semiconductor layer. Conductive semiconductor layer 501, P-type semiconductor contact layer 601 (in direct contact with the P electrode, used to adjust the contact resistance between the P electrode and the P-type semiconductor interface) and P electrode 701; between the N electrode 101 and the N-type semiconductor contact layer 201 The interface contact resistance is adjusted by the doping concentration of the N-type semiconduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com