Eye essence containing lactobacillus fermented lysate product and preparation method of essence

A technology of Lactobacillus and cell lysate, applied to medical preparations containing active ingredients, skin care preparations, pharmaceutical formulas, etc., can solve the problem of destroying the normal ecological balance of eye skin, affecting eye skin health, and retention of raw materials and other problems, to achieve the effect of enhancing eye brilliance, removing eye edema, and smoothing fine wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

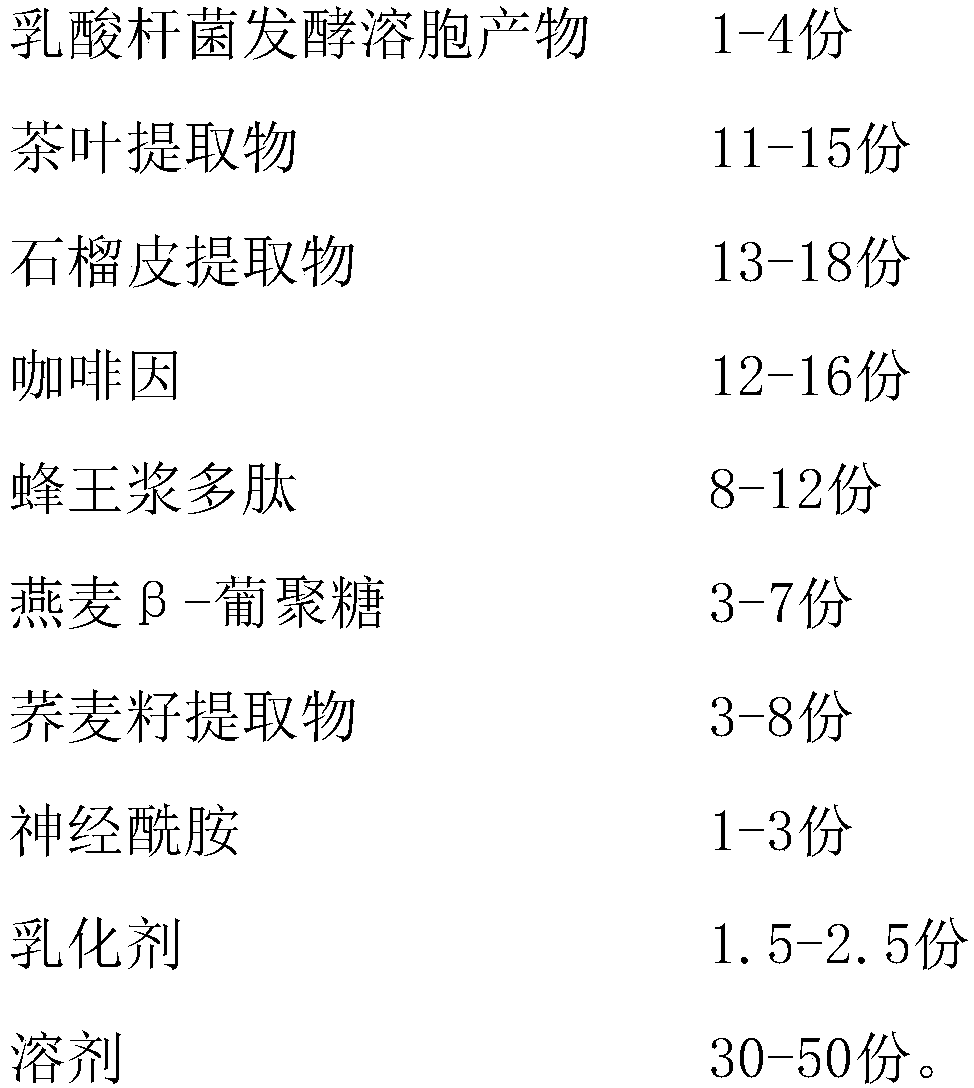

[0050] An eye essence containing a lactobacillus fermentation lysate, the eye essence includes the following raw materials in parts by weight:

[0051]

[0052] The solvent is a mixture of water, spermaceti and glycerin in a weight ratio of 1:2:2.5.

[0053] Described emulsifier is cetearyl olive oil ester.

[0054] The lactobacillus fermentation lysate is prepared by the following method:

[0055] Step (1): planting Lactobacillus strains in the culture medium for expanded culture, then inoculating the expanded cultured Lactobacillus in the fermentation medium, and performing shaking fermentation at a fermentation temperature of 35° C. to obtain a fermentation liquid;

[0056] Step (2): Centrifuge the fermented liquid in step (1), remove the supernatant to obtain a strain mixture, and then mix the strain mixture, strain emulsifier, and strain protectant in a weight ratio of 1:2:2.5 Mix, stir and emulsify to obtain an emulsion;

[0057] Step (3): Inactivate the emulsion i...

Embodiment 2

[0069] An eye essence containing a lactobacillus fermentation lysate, the eye essence includes the following raw materials in parts by weight:

[0070]

[0071] The solvent is a mixture of water, spermaceti and glycerin in a weight ratio of 1:2.2:2.6.

[0072] The emulsifier is Polyacrylate-13 or Sorbitan Olivate.

[0073] The lactobacillus fermentation lysate is prepared by the following method:

[0074] Step (1): Planting Lactobacillus strains in the culture medium for expanded culture, then inoculating the expanded cultured Lactobacillus in the fermentation medium, and performing shaking fermentation at a fermentation temperature of 38° C. to obtain a fermentation liquid;

[0075] Step (2): Centrifuge the fermented liquid in step (1), remove the supernatant to obtain a strain mixture, and then mix the strain mixture, strain emulsifier, and strain protectant in a weight ratio of 1:2.2:2.8 Mix, stir and emulsify to obtain an emulsion;

[0076] Step (3): Inactivate the e...

Embodiment 3

[0088] An eye essence containing a lactobacillus fermentation lysate, the eye essence includes the following raw materials in parts by weight:

[0089]

[0090] The solvent is a mixture of water, spermaceti and glycerin in a weight ratio of 1:2.5:2.

[0091] Described emulsifier is glyceryl stearate.

[0092] The lactobacillus fermentation lysate is prepared by the following method:

[0093] Step (1): Planting the Lactobacillus species in the culture medium for expanded culture, then inoculating the expanded cultured Lactobacillus in the fermentation medium, and performing shaking fermentation at a fermentation temperature of 42° C. to obtain a fermentation liquid;

[0094] Step (2): Centrifuge the fermented liquid in step (1), remove the supernatant to obtain a strain mixture, and then mix the strain mixture, strain emulsifier, and strain protectant in a weight ratio of 1:2.5:3.5 Mix, stir and emulsify to obtain an emulsion;

[0095] Step (3): Inactivate the emulsion in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com