Preparation method and application of crosslinked formaldehyde-free color fixing agent RF

An aldehyde-free color-fixing agent and reaction technology, applied in the direction of dyeing, textile and papermaking, etc., to achieve the effect of small color change, improved fastness, and excellent color-fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0021] A preparation method of crosslinked formaldehyde-free color fixing agent RF, comprising the steps of:

[0022] (1) Prepare polyurethane prepolymer solution:

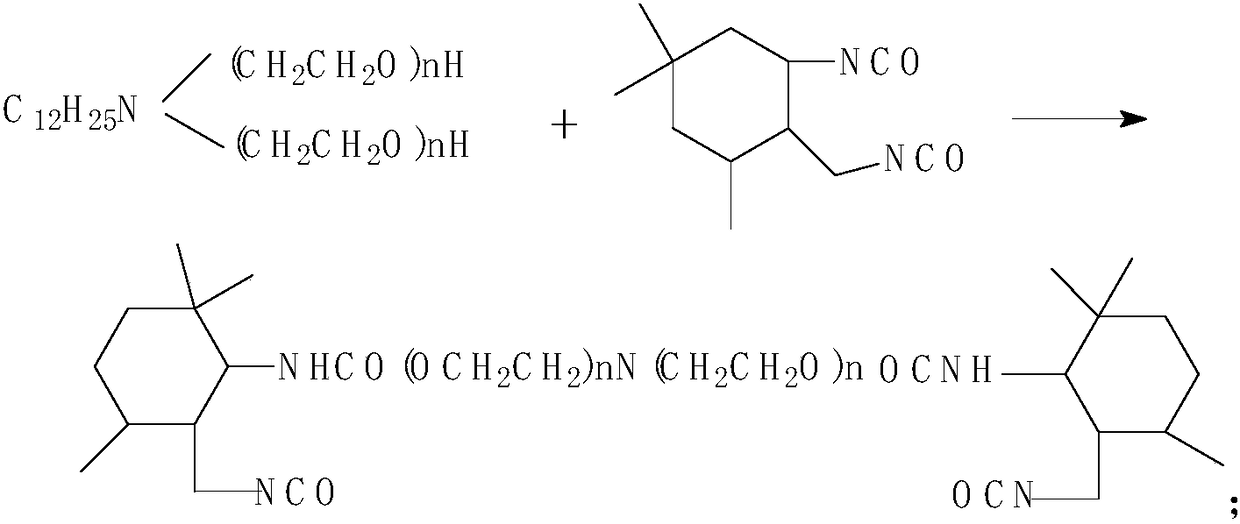

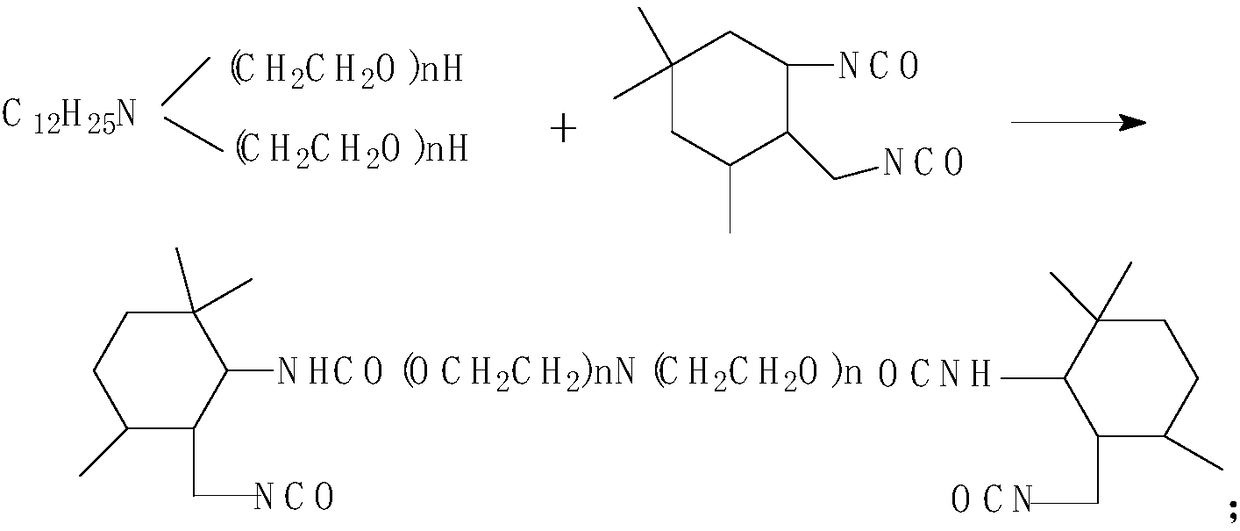

[0023] In a 500mL four-neck flask equipped with a stirrer, a thermometer, and a condensing reflux tube, add dehydrated isophorone diisocyanate (IPDI) and hydrophilic chain extender tertiary amine polyoxyethylene ether (molecular weight: 600) in proportion. , heated up to 40°C, and reacted for 1 hour to obtain a polyurethane prepolymer solution; the chemical reaction was as follows:

[0024]

[0025] (2) Preparation of cross-linked formaldehyde-free color fixing agent RF:

[0026] Cool down the prepared polyurethane prepolymer solution to room temperature, add acetone to adjust the viscosity of the system, add metered acetic acid to neutralize the reaction for 20 minutes, add metered sodium bisulfite to capping reaction for 30 minutes, add water to high-speed stirring emulsification, and finally depressurize to...

specific Embodiment 2

[0033] A preparation method of crosslinked formaldehyde-free color fixing agent RF, comprising the steps of:

[0034] (1) Prepare polyurethane prepolymer solution:

[0035] In a 500mL four-neck flask equipped with a stirrer, a thermometer, and a condensing reflux tube, add dehydrated isophorone diisocyanate (IPDI) and hydrophilic chain extender tertiary amine polyoxyethylene ether (molecular weight: 600) in proportion. , heated up to 60°C, and reacted for 2 hours to obtain a polyurethane prepolymer solution; the chemical reaction was as follows:

[0036]

[0037] (2) Preparation of cross-linked formaldehyde-free color fixing agent RF:

[0038] Cool the prepared polyurethane prepolymer solution to room temperature, add acetone to adjust the viscosity of the system, add metered acetic acid for neutralization reaction for 40 minutes, add metered amount of sodium bisulfite for capping reaction for 50 minutes, add water and high-speed stirring for emulsification, and finally re...

specific Embodiment 3

[0045] A preparation method of crosslinked formaldehyde-free color fixing agent RF, comprising the steps of:

[0046] (1) Prepare polyurethane prepolymer solution:

[0047] In a 500mL four-neck flask equipped with a stirrer, a thermometer, and a condensing reflux tube, add dehydrated isophorone diisocyanate (IPDI) and hydrophilic chain extender tertiary amine polyoxyethylene ether (molecular weight: 600) in proportion. , heated up to 50°C, and reacted for 1.5h to obtain a polyurethane prepolymer solution; the chemical reaction was as follows:

[0048]

[0049] (2) Preparation of cross-linked formaldehyde-free color fixing agent RF:

[0050] Cool the prepared polyurethane prepolymer solution to room temperature, add acetone to adjust the viscosity of the system, add metered acetic acid for neutralization reaction for 30 minutes, add metered amount of sodium bisulfite for capping reaction for 40 minutes, add water and high-speed stirring for emulsification, and finally remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com