TFT array substrate, display device and preparation method of TFT array substrate

An array substrate and metal layer technology, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of difficult to guarantee the reliability of TFT devices, reduce the storage capacitance of TFT devices, and increase the complexity of the process, so as to reduce the pixel area , Saving process cost and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

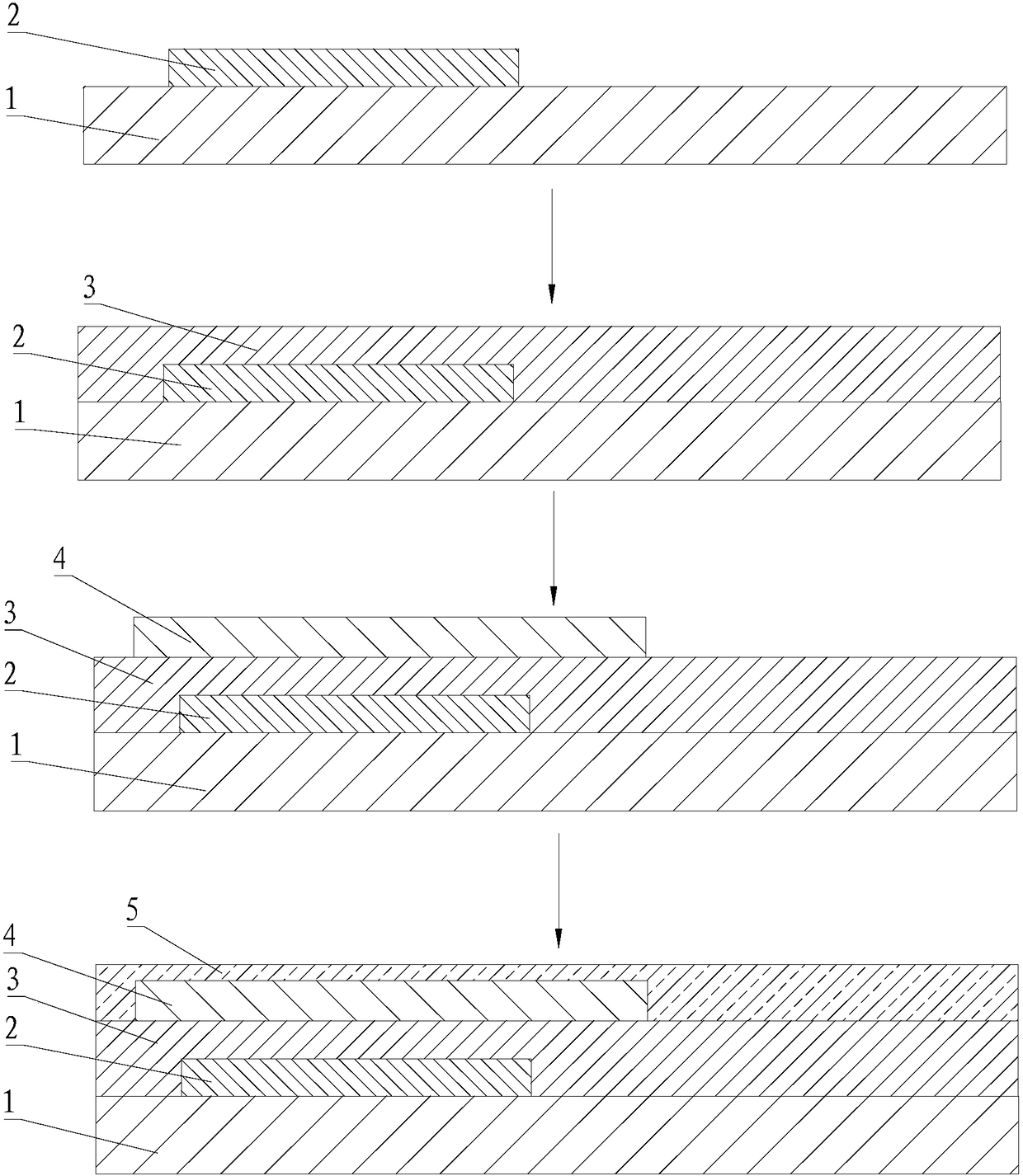

[0040] The present invention also provides a method for preparing a TFT array substrate, comprising the following steps:

[0041] Step 1: sequentially forming a gate, a gate insulating layer, an active layer and an etching barrier layer on the substrate, the gate being formed by a first metal layer;

[0042] Step 2: forming an auxiliary metal layer on the etching barrier layer;

[0043] Step 3: forming a passivation layer on the etching barrier layer and the auxiliary metal layer;

[0044]Step 4: Simultaneously pattern the passivation layer and the etching barrier layer through a patterning process to form a first via hole and a second via hole connected to the active layer;

[0045] Step 5: forming a third metal layer on the passivation layer, the third metal layer is connected to the active layer through the first via hole and the second via hole; A source electrode and a drain electrode are respectively formed at the first via hole and the second via hole.

[0046] Furth...

Embodiment 1

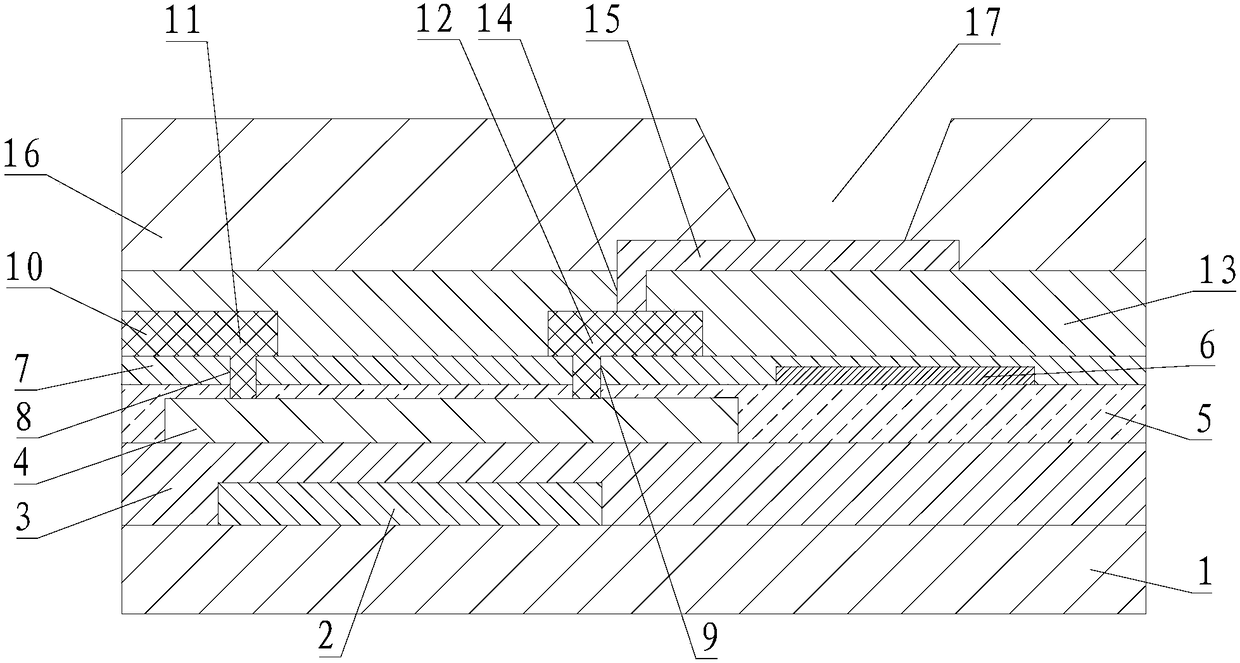

[0053] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0054] A TFT array substrate, comprising a substrate 1, a gate formed by a first metal layer 2 disposed on the substrate 1, a gate insulating layer 3 disposed on the substrate 1 and the gate, and a gate insulating layer 3 disposed on the substrate 1. The active layer 4 on the gate insulating layer 3, the etching stopper layer 5 provided on the active layer 4 and the gate insulating layer 3, the auxiliary metal layer 6 provided on the etching stopper layer 5, The passivation layer 7 disposed on the etch barrier layer 5 and the auxiliary metal layer 6 passes through the passivation layer 7 and the etch barrier layer 5 and corresponds to the upper sides of the active layer 4 respectively. The first via hole 8 and the second via hole 9, the third metal layer 10 provided on the passivation layer 7, the third metal layer 10 passes through the first via hole 8 and the second via hole 9 respectively connec...

Embodiment 2

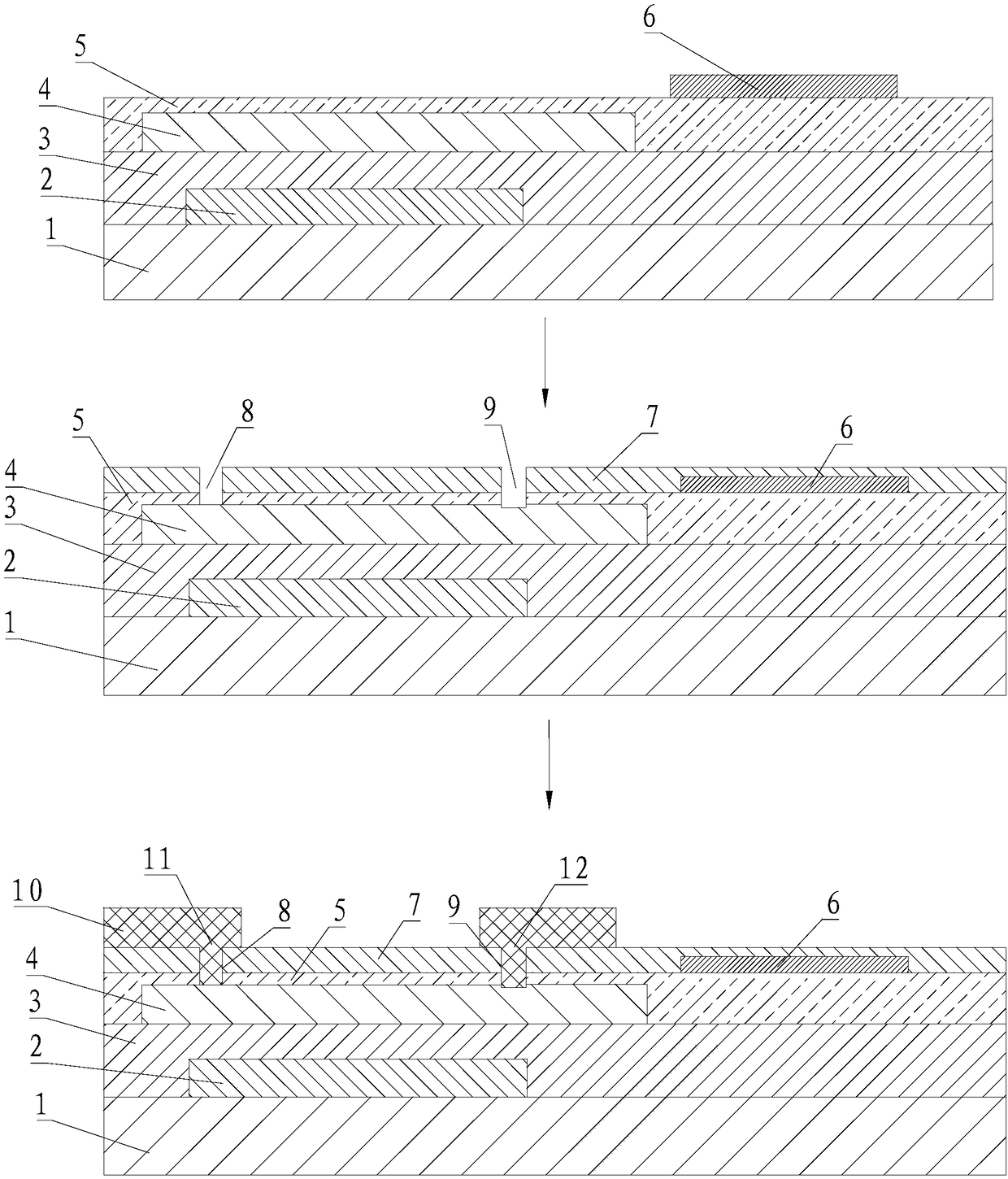

[0059] Please refer to Figure 2 to Figure 4 , the second embodiment of the present invention is:

[0060] A method for preparing a TFT array substrate, comprising the steps of:

[0061] Step 1: Evaporate the first metal layer (M1) 2 on the substrate 1 by physical vapor deposition (PVD), generally with a Mo / AL / Mo sandwich layer structure, and expose (photo) after photoresist coating, according to the mask Plate (MASK) design to form the required pattern, and then etch the first metal layer (M1) 2 to form the pattern of the gate (GE);

[0062] Step 2: Evaporating a gate insulating layer (GI) 3 on the substrate treated in step 1 by chemical vapor deposition (CVD);

[0063] Step 3: Evaporate an IGZO film on the substrate treated in step 2 by PVD method, and go through exposure (photo), etching (etch) and stripping (stripe) processes; finally form the required active layer (SE)4 picture of;

[0064] Step 4: Evaporating an etching stopper layer (ES) 5 on the substrate treated i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com