Thin film encapsulation structure, display device and preparation method of display device

A thin-film packaging and display device technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of short distance between display layers, affecting touch effects, and signal interference on touch layers, so as to improve and prevent , The effect of improving the mechanical properties of the film and improving the electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

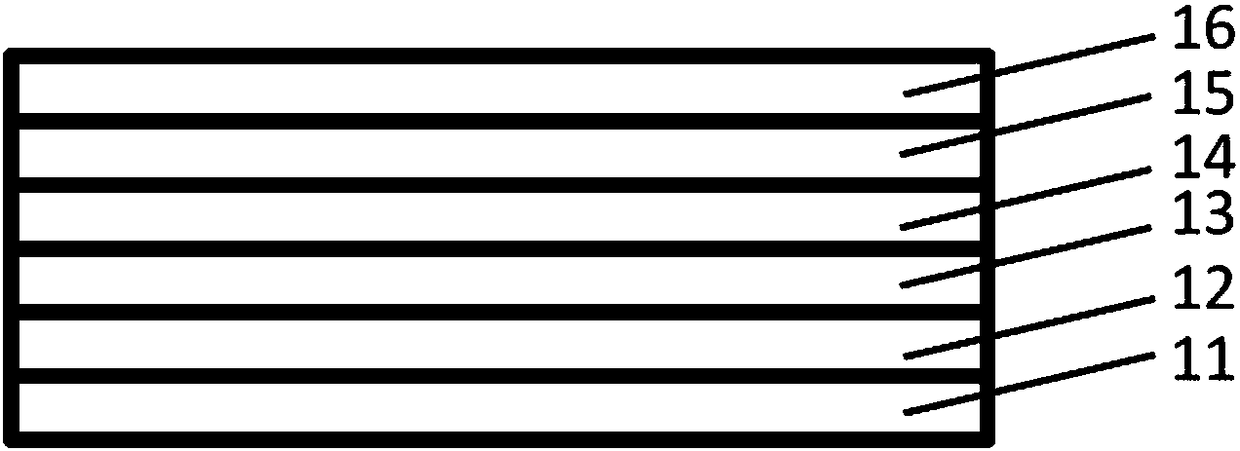

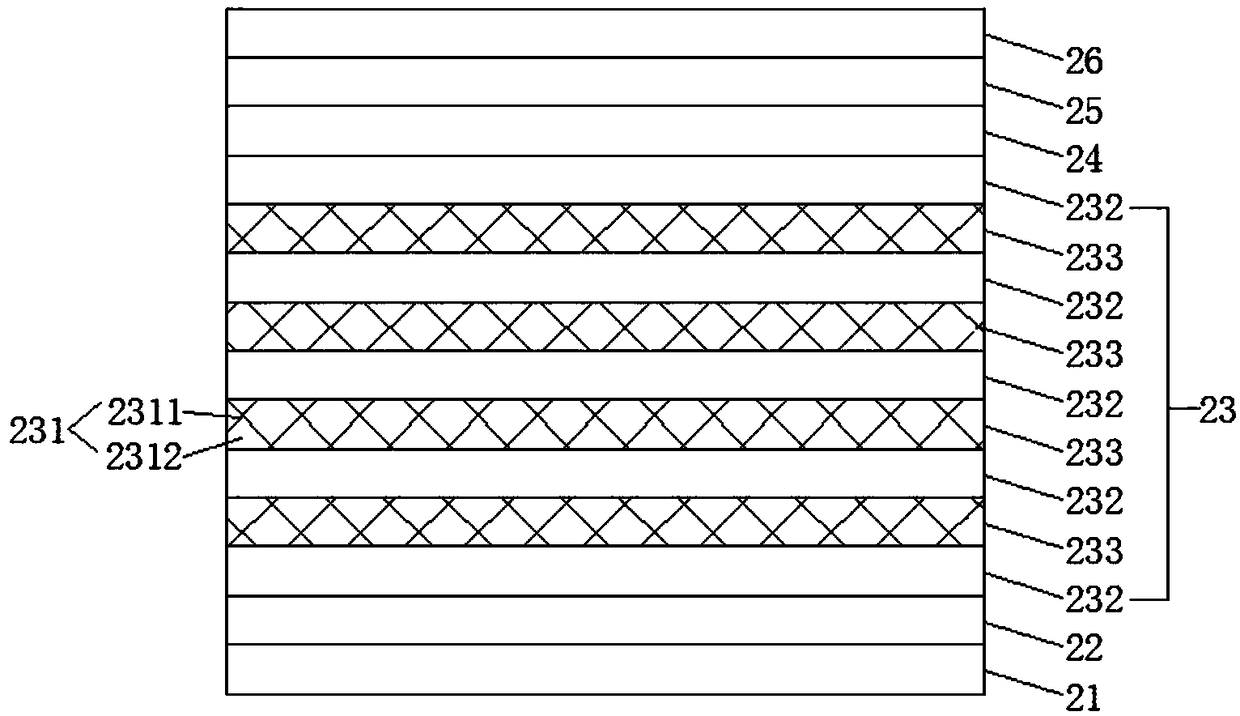

[0040] This embodiment provides a display device, such as figure 2 As shown, it includes a substrate 21, an OLED display layer 22, a film packaging structure 23, a touch layer 24, a polarizer 25 and a cover plate 26.

[0041] The substrate 21 includes a base substrate, a thin film transistor (TFT) array layer provided on the base substrate, and a flat layer on the array layer. The base substrate may be formed of various materials such as glass, plastic, silicon or metal, and preferably, glass is used as the base substrate.

[0042] The OLED display layer 22 is disposed on the substrate 21, and the layer includes organic electroluminescence units (OLED) with R, G, and B three-color pixel arrays. The organic electroluminescence unit has a first electrode, a second electrode, and a first electrode. The organic functional layer between the electrode and the second electrode. Among them, the first electrode is an anode, such as ITO material; the second electrode is a cathode, such as...

Embodiment 2

[0049] This embodiment provides a method for manufacturing the display device as in Embodiment 1, including:

[0050] (1) Provide a substrate 21, and form an OLED display layer 22 on the substrate 21;

[0051] Specifically, a thin film transistor (TFT) array layer is formed on a glass substrate, and a flat layer is formed on the thin film transistor (TFT) array layer; a transparent ITO conductive film is vapor-deposited on the flat layer to obtain an anode; and then the anode is vapor-deposited Hole injection layer, hole transport layer, light emitting layer, electron transport layer, electron injection layer and cathode Mg / Ag to obtain an OLED display layer.

[0052] (2) In step (1), an inorganic material passivation layer 232 and an organic material buffer layer 233 are alternately formed on the OLED display layer 22 in order, wherein an electromagnetic shielding layer 231 is provided in at least one organic material buffer layer 233, Forming a packaging film structure 23;

[0053]...

Embodiment 3

[0057] The present invention provides a display device. The difference from Embodiment 1 is that the thin film encapsulation layer 23 is not provided between the OLED display layer 22 and the touch layer 24, and only the electromagnetic shielding layer 231 is provided. In the display device of this structure, the electromagnetic shielding layer 231 can still shield the interference of the cathode of the OLED display layer 22 to the signal of the touch control layer 24.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com