Graphene carbon electric heater and production process thereof

A graphene carbon and production process technology, applied in the direction of electric heating devices, ohmic resistance heating, ohmic resistance heating parts, etc., can solve the problems of insufficient heating stability, insufficient service life, and insufficient thermal efficiency, and achieve low cost and high-quality products The effect of high efficiency and stable heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

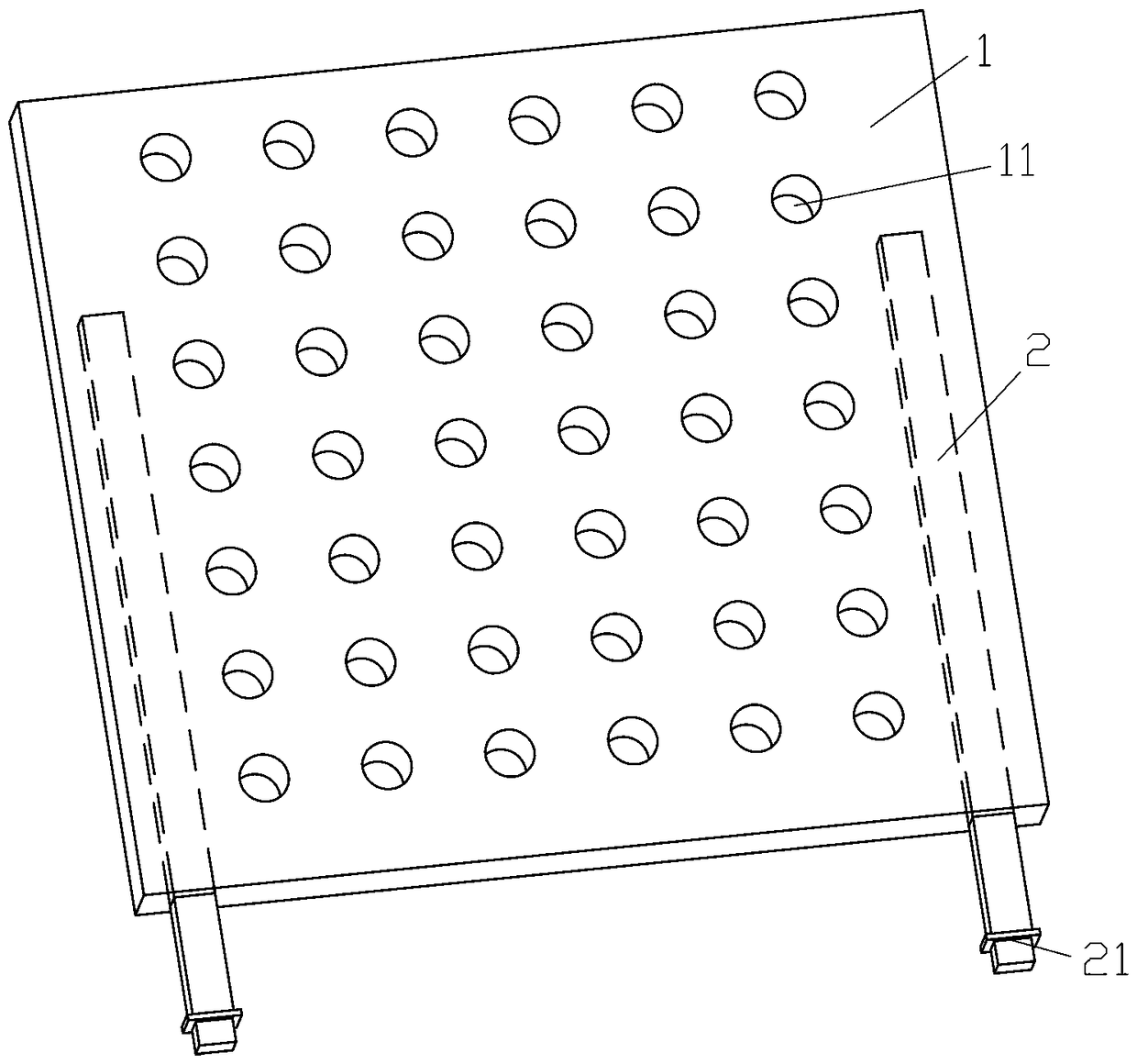

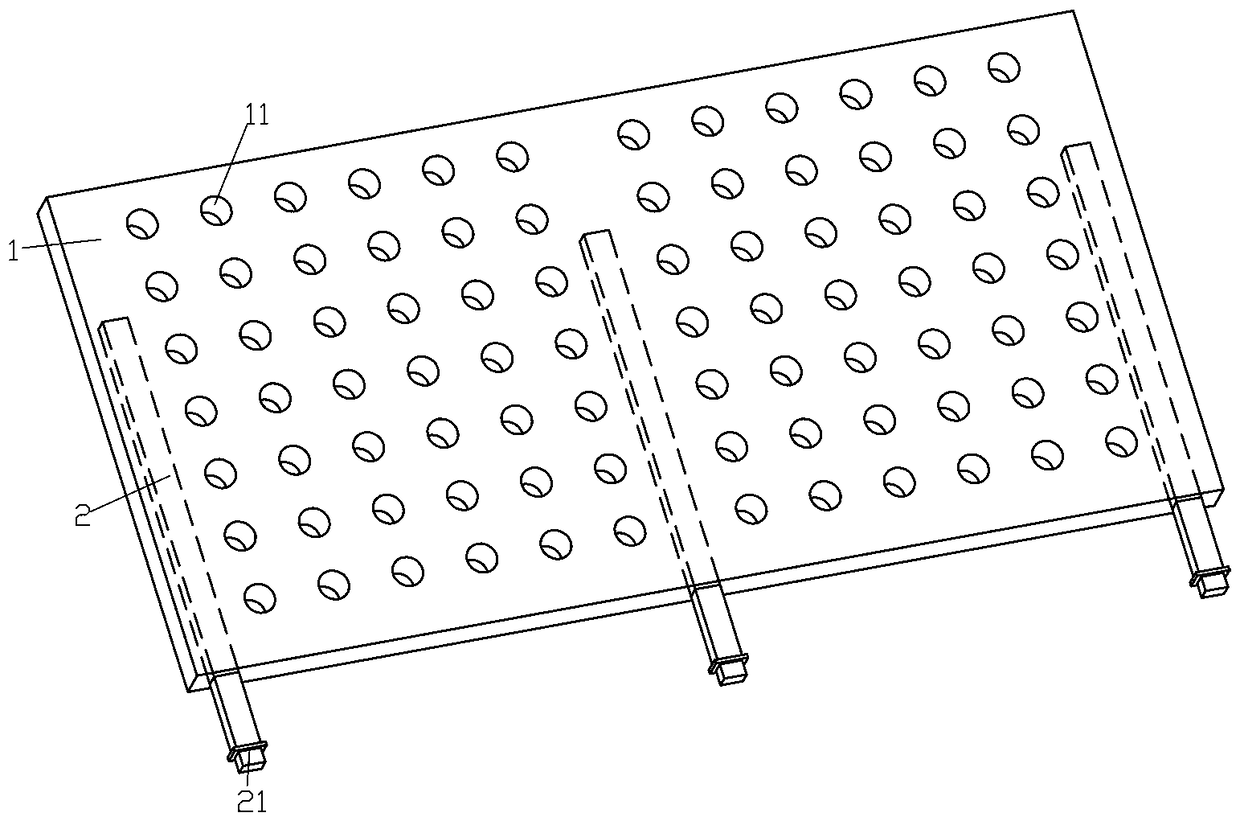

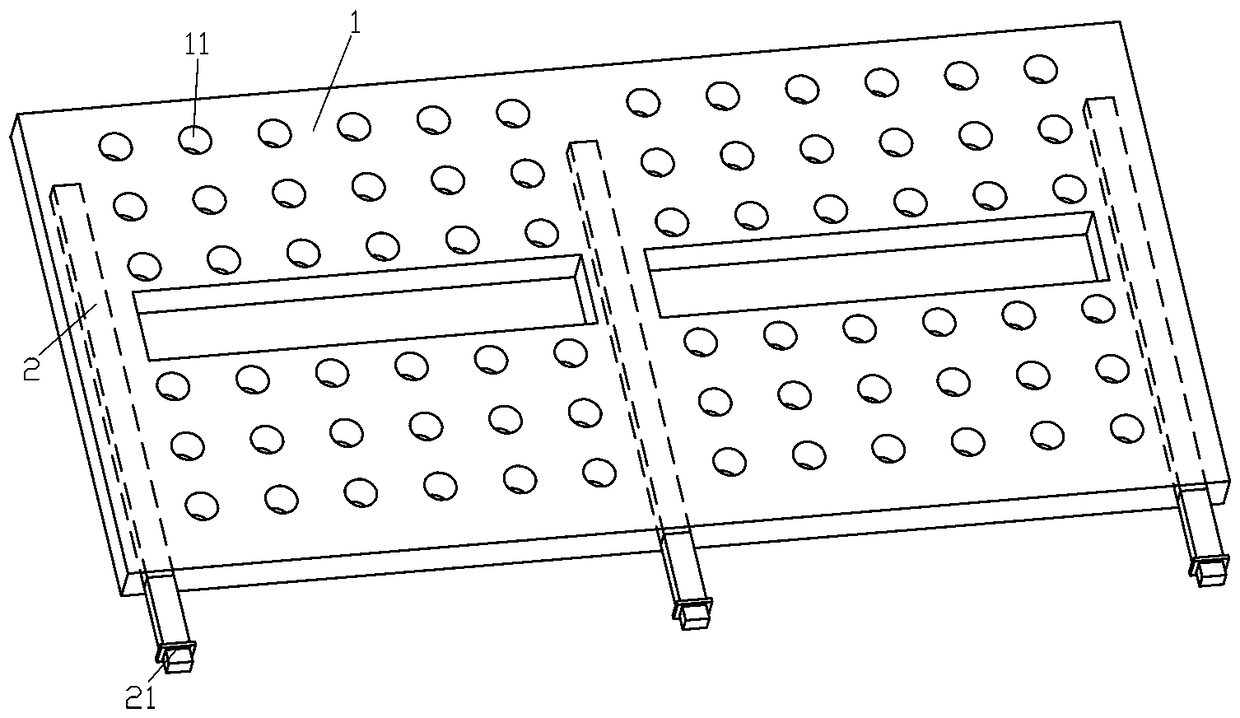

[0026] Embodiment 1, as shown in the figure, a graphene carbon electric heater includes more than two strip-shaped electrodes 2 arranged at intervals, and at least one graphene carbon is connected between two adjacent electrodes 2 The electric heating unit 1, the electrode end 21 of the electrode 2 is outside the graphene carbon electric heating unit 1, and at least 80% of the electrode 2 except the electrode end 21 is inside the graphene carbon electric heating unit 1. The graphene carbon electric heating unit 1 is preferably a graphene carbon composite material plate. By applying voltage to the electrodes, the graphene carbon electric heating unit 1 will generate electric heat when it is energized, with high thermal efficiency, stable heat generation, low cost and long service life.

[0027] In a further design, the graphene carbon electric heating unit 1 has air circulation holes 11 for air circulation. Through the air circulation hole 11, a device for blowing air can be a...

Embodiment 2

[0034] Embodiment 2, a kind of production process of graphene carbon electric heater, when in embodiment 1, when graphene carbon electric heating unit 1 adopts graphene carbon composite material sheet material, just can select the technology of this embodiment for use, specific technological process is, Include the following steps:

[0035] Step 1, prepare raw materials: use graphene as the main material, supplemented with tar, resin, fixed carbon, and conductivity adjusting material;

[0036] Step 2, stirring the raw materials in step 1 and adding them to the molding die and inserting the electrode 2 into the raw materials in the mould, to form a graphene carbon composite electric heater blank;

[0037] Step 3, putting the graphene-carbon composite electric heater blank in step 2 into a carbonization kiln for carbonization to form a finished graphene-carbon electric heater.

[0038] Among them, graphene main material accounts for more than 60% of the total weight of raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com