Preparation method and application of tobacco after-run spice having fragrance of sun-cured red tobacco

A technology for drying red smoke and wine tail, which is applied in the field of preparation of wine tail spices for tobacco, which can solve problems such as rough craftsmanship, and achieve the effect of improving the sensory quality of aroma, distinct style, and prominent tobacco aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

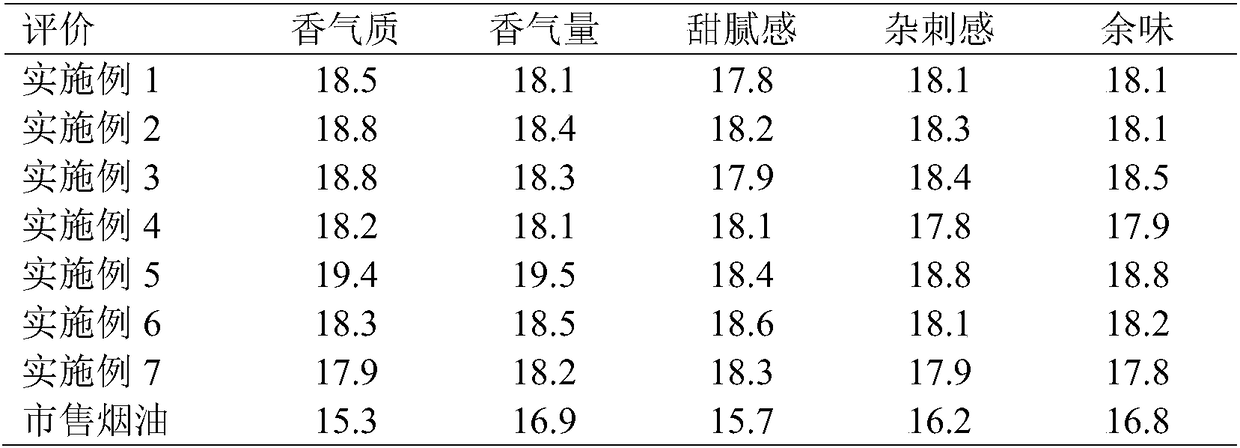

Embodiment 1

[0024] A preparation method of a wine tail flavor for tobacco with the aroma of sun-cured red smoke, comprising the steps of:

[0025] Step 1. Take 50g of Jiangxi characteristic "Black Tiger" sun-dried red tobacco leaves, grind them into powder, add 250g of sorghum wine tails to extract at 40-50°C, add 0.1g of mixed enzyme liquid of sun-dried red tobacco quality, stir evenly, at 45-50°C Enzymolysis under natural conditions of ℃ and pH for 6 hours to obtain wine tail extract A;

[0026] The mixed enzyme liquid is made by mixing red yeast rice esterase, compound plant hydrolase, and amylase at a mass ratio of 1:5:5, wherein the red yeast esterase is food grade, with an enzyme activity of 150u / g, and the compound plant hydrolyzes The enzyme is food grade, the enzyme activity is 10000u / g, the amylase is food grade, the enzyme activity is 10000u / g;

[0027] Step 2: Add 500 g of 95% ethanol to wine tail extract A for alcohol precipitation, filter with suction, and concentrate the f...

Embodiment 2

[0035] A preparation method of a wine tail flavor for tobacco with the aroma of sun-cured red smoke, comprising the steps of:

[0036] Step 1. Take 50g of Jiangxi characteristic "Black Tiger" sun-dried red tobacco leaves, grind them into powder, add 300g of sorghum wine to extract at 40-50°C, add 0.05g of mixed enzyme solution of sun-dried red tobacco quality, stir evenly, at 45-50 Enzymolysis under natural conditions of ℃ and pH for 7 hours to obtain wine tail extract A;

[0037] The mixed enzyme solution is composed of red yeast rice esterase, compound plant hydrolase, and amylase in a mass ratio of 1:6:10, wherein the red yeast esterase is food grade, with an enzyme activity of 200u / g, and the compound plant hydrolyzes The enzyme is food grade, the enzyme activity is 10000u / g, the amylase is food grade, the enzyme activity is 20000u / g;

[0038] Step 2: Add 500 g of 95% ethanol to the wine tail extract A for alcohol precipitation, filter with suction, and concentrate the fi...

Embodiment 3

[0046] A preparation method of a wine tail flavor for tobacco with the aroma of sun-cured red smoke, comprising the steps of:

[0047] Step 1. Take 50g of Jiangxi characteristic "Black Tiger" sun-dried red tobacco leaves, grind and beat them into powder, add 350g of sorghum wine tails for extraction at 40-50°C, add 0.025g of mixed enzyme liquid of sun-dried red tobacco quality, stir evenly, at 45-50 Enzymolysis under natural conditions of ℃ and pH for 8 hours to obtain wine tail extract A;

[0048] The mixed enzyme liquid is made by mixing red yeast rice esterase, compound plant hydrolase, and amylase in a mass ratio of 2:5:8, wherein the red yeast esterase is food grade, with an enzyme activity of 150u / g, and the compound plant hydrolyzes The enzyme is food grade, the enzyme activity is 10000u / g, the amylase is food grade, the enzyme activity is 20000u / g;

[0049] Step 2: Add 1000 g of 95% ethanol to wine tail extract A for alcohol precipitation, filter with suction, and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com