Industrial flue gas dioxins precursor remover

A technology for dioxins and industrial flue gas, applied in gas treatment, membrane technology, other chemical processes, etc., can solve problems such as limited adsorption, high cost, fire, explosion, etc., achieve obvious removal effect, ideal effect, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

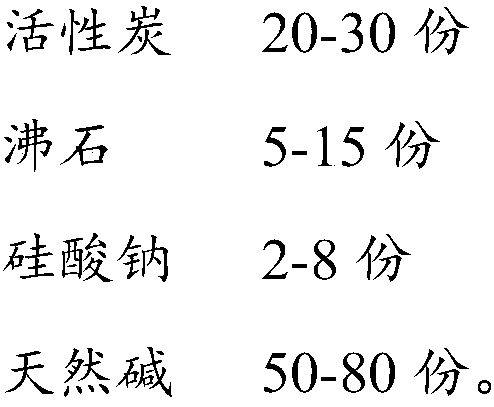

Method used

Image

Examples

Embodiment 1

[0027] At room temperature, soak powdered activated carbon with a particle diameter of 20 μm in an aqueous sodium silicate solution in which 4 parts of sodium silicate is dissolved in water, evaporate water while stirring, and dry the activated carbon after evaporating water.

[0028] According to parts by weight, 26 parts of activated carbon added with sodium silicate, 10 parts of powdered zeolite with a particle diameter of 20 μm, and 60 parts of powdered trona with a particle diameter of 20 μm can be uniformly mixed.

Embodiment 2

[0030] At normal temperature, according to the parts by weight, 10 parts of zeolite and 60 parts of trona are pulverized, and then 30 parts of activated carbon added with 4 parts of sodium silicate are added and mixed evenly.

Embodiment 3

[0032] At room temperature, soak powdered activated carbon with a particle size of 20 μm in an aqueous sodium silicate solution in which 2 parts of sodium silicate is dissolved in water, evaporate the water while stirring, and dry the activated carbon after evaporating the water.

[0033] According to parts by weight, 20 parts of activated carbon added with sodium silicate, 5 parts of powdered zeolite with a particle diameter of 20 μm, and 50 parts of powdered trona with a particle diameter of 20 μm can be uniformly mixed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com