Preparation method of water-retentive high-toughness building mortar

A toughness and mortar technology, applied in the field of water-retaining and high-toughness building mortar preparation, can solve the problems of low tensile strength and bond strength, high elastic modulus, poor water retention, etc., to improve toughness and elasticity, high toughness, increase Hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

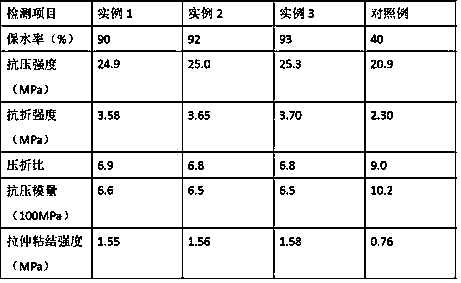

Examples

example 1

[0021] Collect the ramie stems and cut them into 10cm ramie segments with a guillotine, put the ramie segments into the blasting tank, pressurize the pressure in the blasting tank to 0.9MPa with a booster pump, and open the blasting tank after 1-2 minutes of pressure-holding treatment. The exhaust valve reduces the pressure in the blasting tank to normal pressure instantaneously, and discharges the material to obtain a micro-exploded ramie section; spread the obtained micro-exploded ramie section on the ground, and repeatedly rolls it with a stone roller for 15 minutes. After the rolling, a loose ramie section is obtained. For ramie fiber bundles, mix the ramie fiber bundles with 20% sodium hydroxide solution in a mass ratio of 1:10, put them in a water bath, and soak for 10 hours at a water bath temperature of 50°C; after soaking, filter Separate the filter residue, mix the filter residue with water and lemon juice at a mass ratio of 2:10:1, put it into a high-pressure cooking...

example 2

[0023]Collect the ramie stalks and cut them into 10cm ramie segments with a guillotine, put the ramie segments into the blasting tank, pressurize the pressure inside the blasting tank to 0.9MPa with a booster pump, keep the pressure for 2 minutes, and then open the exhaust of the blasting tank Valve, so that the pressure in the blasting tank is instantly reduced to normal pressure, and the material is discharged to obtain a micro-exploded ramie segment; the obtained micro-exploded ramie segment is flattened on the ground, and rolled repeatedly with a stone roller for 18 minutes, and loose ramie fibers are obtained after the rolling. bundles, mix ramie fiber bundles and 20% sodium hydroxide solution in a mass ratio of 1:10, put them in a water bath, and soak for 11 hours at a water bath temperature of 55°C; after soaking, filter and separate to obtain Filter residue, mix the filter residue, water and lemon juice at a mass ratio of 2:10:1, put it into a high-pressure cooking tank...

example 3

[0025] Collect the ramie stalks and cut them into 10cm ramie segments with a guillotine, put the ramie segments into the blasting tank, pressurize the pressure in the blasting tank to 1.0MPa with a booster pump, and open the blasting tank to exhaust after 2 minutes of pressure maintaining Valve, so that the pressure in the blasting tank is instantly reduced to normal pressure, and the material is discharged to obtain a micro-exploded ramie segment; the obtained micro-exploded ramie segment is flattened on the ground, and rolled repeatedly with a stone roller for 20 minutes, and loose ramie fibers are obtained after rolling. bundles, mix ramie fiber bundles and 20% sodium hydroxide solution in a mass ratio of 1:10, put them in a water bath, and soak for 12 hours at a water bath temperature of 60°C; after soaking, filter and separate to obtain Filter residue, mix the filter residue, water and lemon juice at a mass ratio of 2:10:1, put it into a high-pressure cooking tank, heat it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com