A kind of anti-fog/anti-frost coating containing anionic polyelectrolyte copolymer and preparation method thereof

A technology of anionic electrolyte and polyelectrolyte, applied in the direction of coating, etc., can solve the problems of low environmental pollution, etc., and achieve the effects of fast curing speed, simple preparation method and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

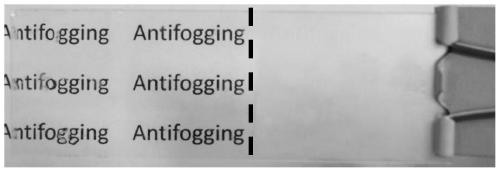

Image

Examples

Embodiment 1

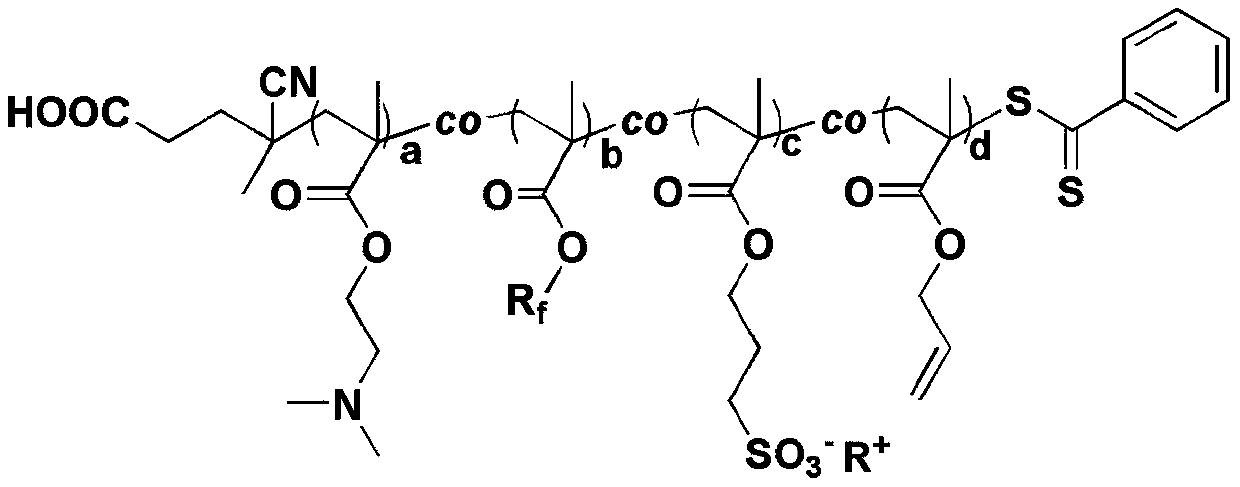

[0040] (1) Synthesis of poly(dimethylaminoethyl methacrylate-co-trifluoroethyl methacrylate-co-3-propyl methacrylate potassium salt-co-allyl methacrylate):

[0041] Dimethylaminoethyl methacrylate, trifluoroethyl methacrylate, potassium salt of 3-propyl methacrylate, allyl methacrylate, 4-cyanovaleric acid dithiobenzoic acid, even The molar ratio of nitrogen bis(isobutyronitrile) is 150:20:30:5:1:0.2 Weigh the medicine, configure it into a 50% trifluoroethanol solution, place it in a 70°C oil bath for 12 hours, after the reaction, the crude product Dialyzed with deionized water for 48h, and obtained the target polymer after freeze-drying, and its structural formula is:

[0042]

[0043] (2) Preparation of anti-fog / anti-frost coating containing anionic polyelectrolyte copolymer:

[0044] Poly(dimethylaminoethyl methacrylate-co-trifluoroethyl methacrylate-co-3-sulfopropyl methacrylate potassium salt-co-allyl methacrylate): 3.46%;

[0045] Oligoethylene glycol dimethacrylate...

Embodiment 2

[0054] (1) Synthesis of poly(dimethylaminoethyl methacrylate-co-hexafluorobutyl methacrylate-co-3-propyl methacrylate potassium salt-co-allyl methacrylate):

[0055] Dimethylaminoethyl methacrylate, hexafluorobutyl methacrylate, potassium salt of 3-propyl methacrylate, allyl methacrylate, 4-cyanovaleric acid dithiobenzoic acid, even The molar ratio of nitrogen bis(isobutyronitrile) is 100:20:30:5:1:0.2 Weigh the medicine, configure it into a 50% trifluoroethanol solution, place it in a 60°C oil bath for 24 hours, after the reaction, the crude product Dialyzed with deionized water for 48h, and obtained the target polymer after freeze-drying, and its structural formula is:

[0056]

[0057] (2) Preparation of anti-fog / anti-frost coating containing anionic polyelectrolyte copolymer:

[0058] Poly(dimethylaminoethyl methacrylate-co-hexafluorobutyl methacrylate-co-3-sulfopropyl methacrylate potassium salt-co-allyl methacrylate): 2%;

[0059] Oligoethylene glycol dimethacrylate...

Embodiment 3

[0068] (1) Synthesis of poly(dimethylaminoethyl methacrylate-co-dodecafluoroheptyl methacrylate-co-3-sulfopropyl methacrylate potassium salt-co-allyl methacrylate) :

[0069] Dimethylaminoethyl methacrylate, dodecafluoroheptyl methacrylate, 3-sulfopropyl methacrylate potassium salt, allyl methacrylate, 4-cyanovaleric acid dithiobenzoic acid, The molar ratio of azobisisobutyronitrile is 500:200:200:20:1:0.2, and the medicine is weighed, configured into a 20% trifluoroethanol solution, and placed in an oil bath at 60°C for 6 hours. After the reaction, the crude The product was dialyzed with deionized water for 48 hours, and the target polymer was obtained after lyophilization, and its structural formula was:

[0070]

[0071] (2) Preparation of anti-fog / anti-frost coating containing anionic polyelectrolyte copolymer:

[0072] Poly(dimethylaminoethyl methacrylate-co-dodecafluoroheptyl methacrylate-co-3-sulfopropyl methacrylate potassium salt-co-allyl methacrylate): 30%;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com