High-temperature-resistant and high-salt-resistant active agent capable of reducing ultra-low permeability oil reservoir starting pressure gradient

A start-up pressure gradient and ultra-low permeability technology, applied in the field of oil and gas fields, can solve the problems of difficult water injection and high start-up pressure gradient, and achieve good salt tolerance, lower start-up pressure gradient, and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

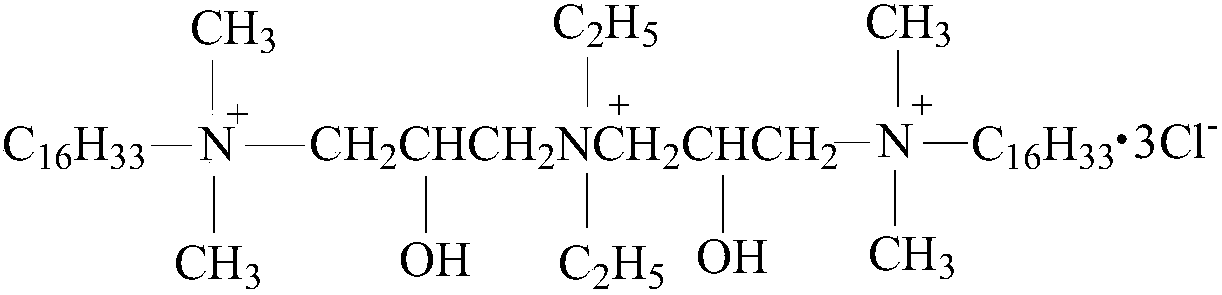

[0032] Example 1 Preparation of a high-temperature-resistant high-salt active agent that can reduce the start-up pressure gradient of ultra-low permeability reservoirs

[0033] The components are: dihexadecyl triquaternary ammonium salt surfactant BDT-16: 22.5%; nonylphenol polyoxyethylene ether phosphate surfactant HSD: 20%; compound organic alcohol YCH: 2.2%; organic anti-swelling agent Agent FPJ: 3.8%; the balance is water. The composite organic alcohol YCH is composed of myristyl alcohol and cetyl alcohol, and the molar ratio of the two is 1:2.

[0034]The preparation method is as follows: add part of water (50% water in the total amount of water) to the reaction kettle, then add dihexadecyl triquaternary ammonium salt surfactant BDT-16, nonylphenol polyoxyethylene ether phosphate surfactant agent HSD, compound organic alcohol YCH and organic anti-swelling agent FPJ, and finally add the remaining water, stir evenly, and it is ready.

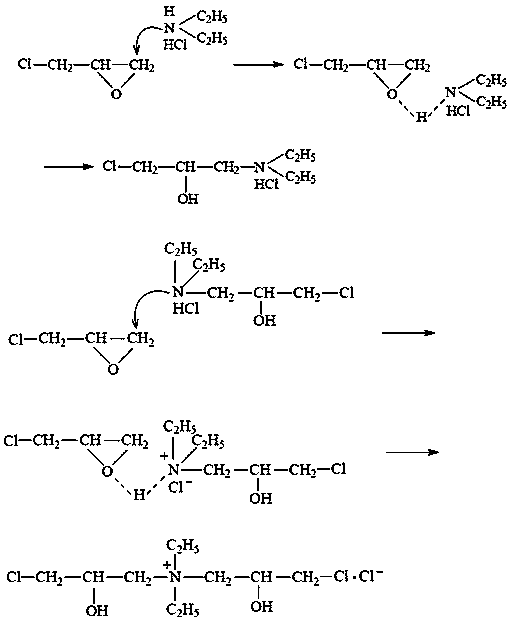

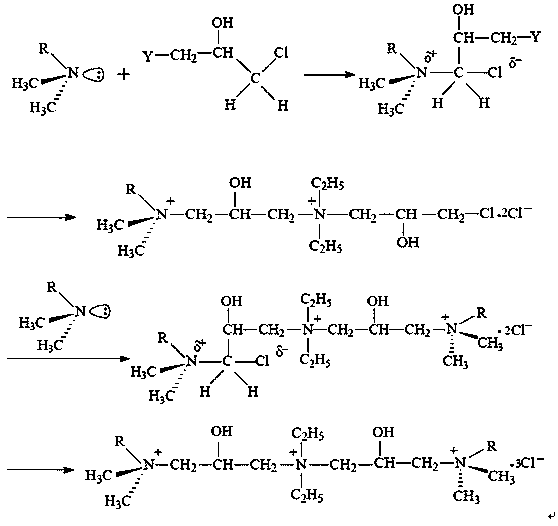

[0035] Wherein, the preparation meth...

Embodiment 2

[0045] Example 2 Preparation of a high-temperature-resistant high-salt active agent that can reduce the start-up pressure gradient of ultra-low permeability reservoirs

[0046] The components are: BDT-16: 23% dihexadecyl triquaternary ammonium salt surfactant; HSD: 19% nonylphenol polyoxyethylene ether phosphate surfactant; 2.3% compound organic alcohol YCH; organic anti-swelling agent Agent FPJ: 3.7%; the balance is water.

[0047] Others are with embodiment 1.

Embodiment 3

[0048] Example 3 Preparation of a high-temperature-resistant high-salt active agent that can reduce the start-up pressure gradient of ultra-low permeability reservoirs

[0049] The components are: BDT-16: 22% dihexadecyl triquaternary ammonium salt surfactant; HSD: 21% nonylphenol polyoxyethylene ether phosphate surfactant; 2.1% compound organic alcohol YCH; organic anti-swelling Agent FPJ: 3.9%; the balance is water.

[0050] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com