Bottom covering sheet and preparation method thereof

A technology of negative film and bottom plate, which is applied in the direction of special materials for cooking utensils, etc., can solve problems such as falling off, loose stainless steel plates, and affecting the use of aluminum pots, so as to reduce the gap between thermal expansion and cold contraction, save nickel metal or nickel alloy, The effect of strengthening the ability to prevent oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

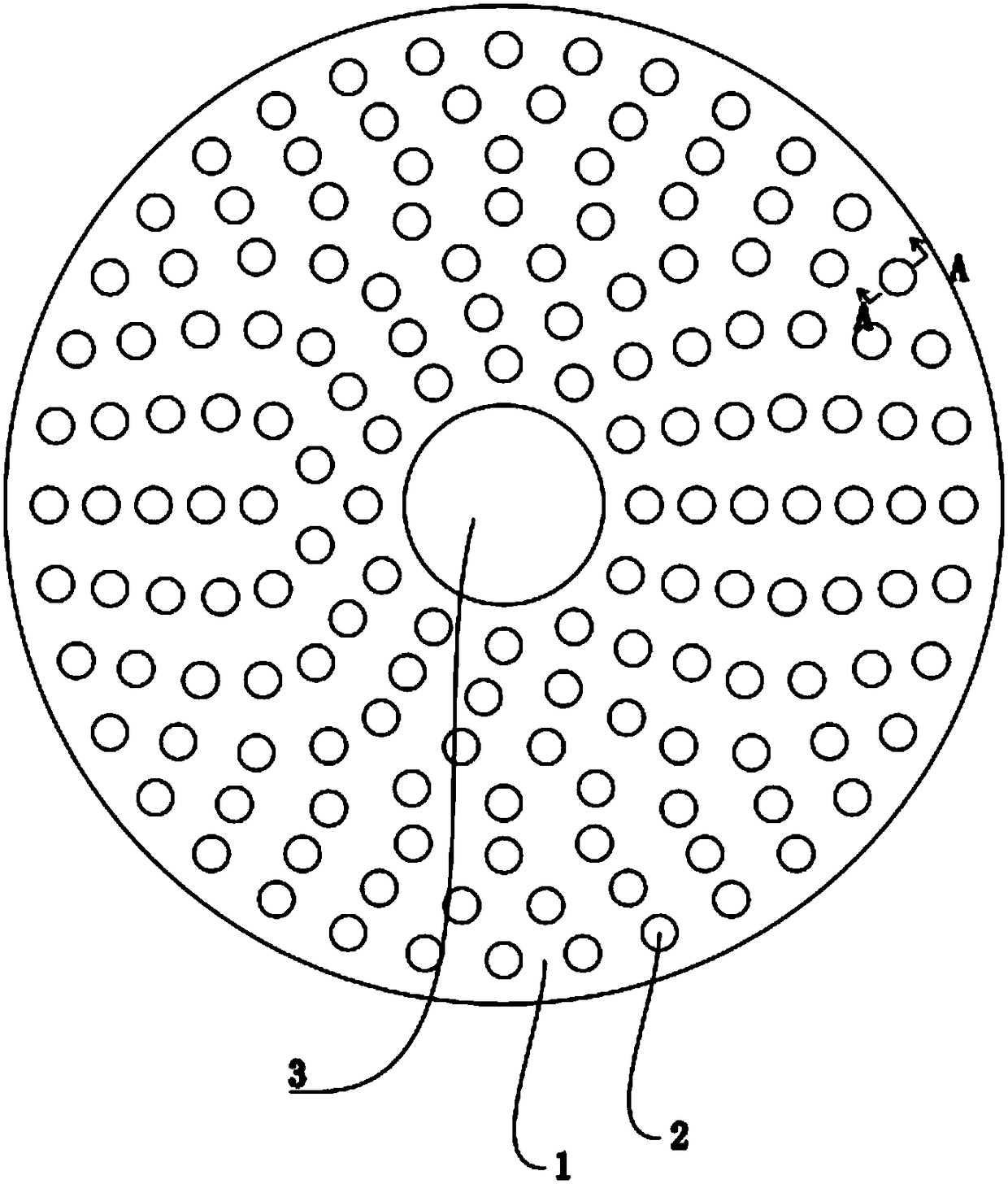

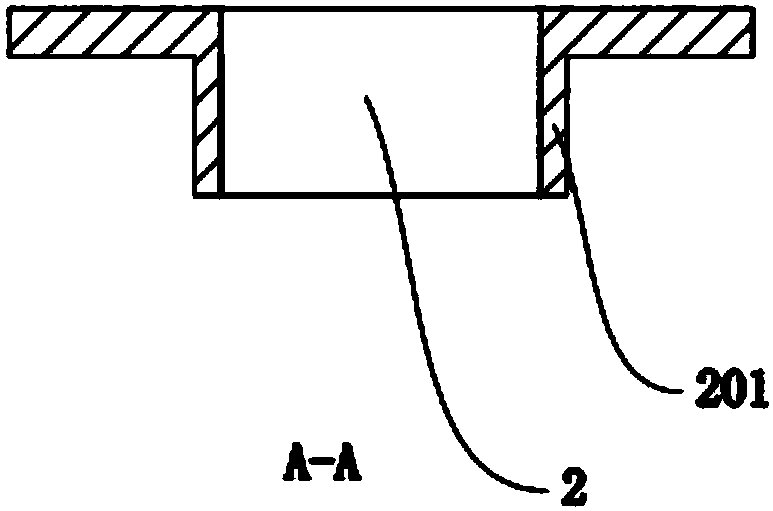

[0029] like figure 1 As shown, a negative-covering sheet includes a circular bottom plate 1, a perforation 3 is provided in the center of the circular bottom plate 1, and a plurality of buffer holes 2 are evenly distributed between the perforation 3 and the edge of the bottom plate 1, as figure 2 As shown, the edge of each buffer hole 2 protrudes to one side of the vertical bottom plate 1 to form a hole shoulder 201, and the hole shoulder 201 is convenient for inserting the bottom sheet into the bottom of the pot when it is attached to the bottom of the pot, so that the bottom sheet and the bottom of the pot are tightly bonded together . The buffer hole 2 is set so that when the expansion and contraction of the base plate and the bottom of the pot body are inconsistent when heated, the inconsistent deformation can be alleviated by the expansion and contraction of the buffer hole 2, and the expansion and contraction of the base plate can also be eased by the perforation 3 , s...

Embodiment 2

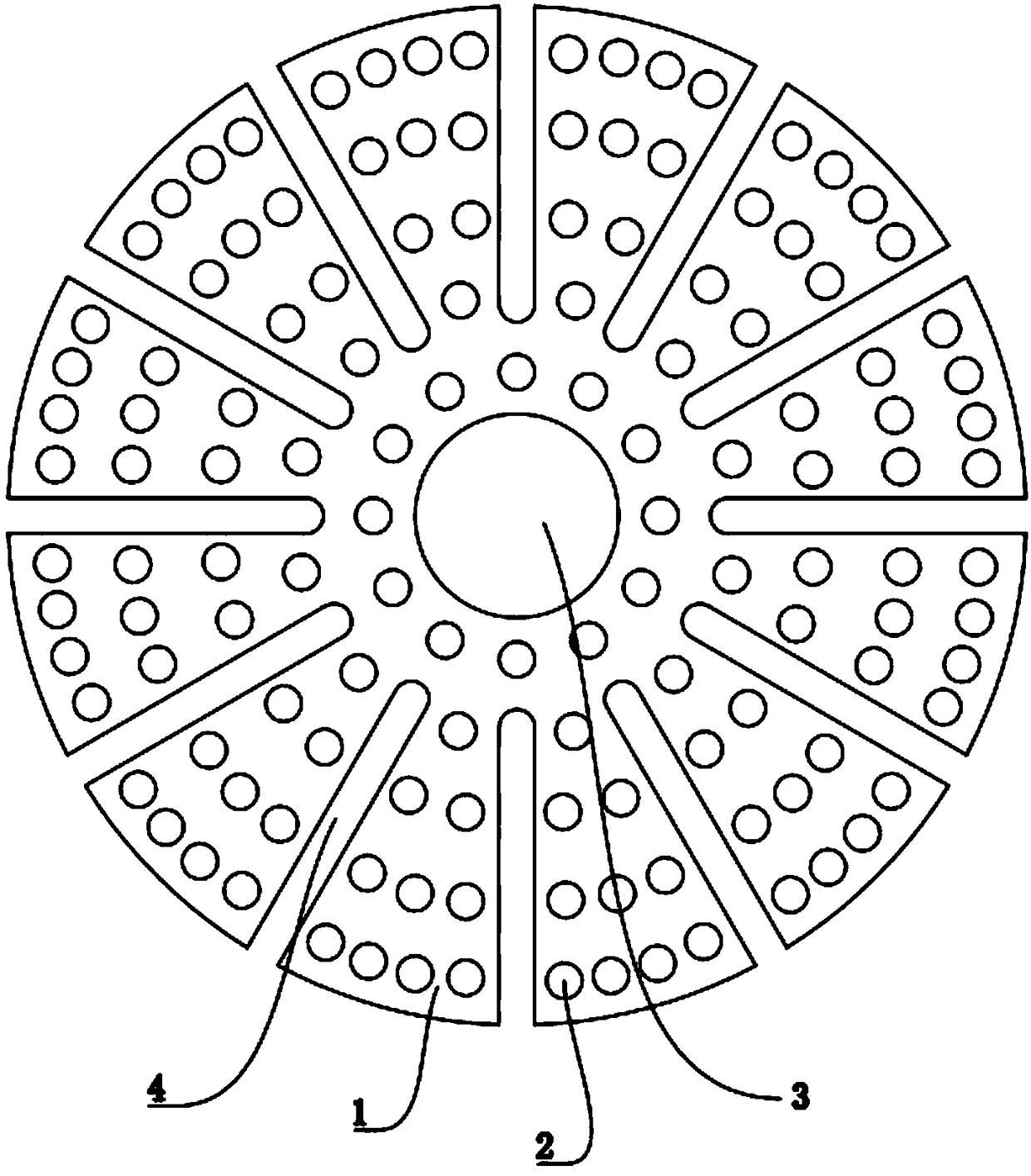

[0038] like figure 2 As shown, in addition to the circular bottom plate 1 , the perforated hole 3 and the buffer hole 2 , the bottom-covering sheet is provided with a plurality of outwardly opening buffer grooves 4 at intervals in the middle of the circular bottom plate 1 . The opening of the buffer groove 4 is outward, that is, a gap is formed on the edge of the negative film, so that the expansion and contraction of the edge of the negative film can be converted into the expansion and contraction of the gap, and the expansion and contraction of the negative film can be alleviated by the existence of the buffer groove 4, thereby making it easier The gap between thermal expansion and contraction between the aluminum alloy pan body and the cladding film is greatly reduced, and the defect of the arch in the middle of the integral cladding film can be completely eliminated, and the combination between the aluminum alloy pan body and the cladding film can be enhanced. Adhesion. ...

Embodiment 3

[0047] A negative film, comprising the following components by weight: C: 0.08 parts, Mn: 10 parts; Si: 4.2 parts; P: 0.017 parts; S: 0.017 parts; Cr: 15 parts; Ti: 0.42 parts; Mo: 0.7 parts; N: 0.35 parts; Zr: 0.22 parts, and the balance is iron.

[0048] A preparation method of a negative-coated film, comprising the steps of:

[0049] Step 1, taking each raw material according to weight components;

[0050] Step 2, putting the weighed raw materials into a vacuum induction furnace for smelting in turn, and blowing nitrogen gas into the molten steel after completely melting into molten steel;

[0051] Step 3, pouring the molten steel obtained in Step 2 into a mold, and casting to obtain a stainless steel workpiece;

[0052] Step 4: Take out the stainless steel workpiece formed in step 3 and perform quenching treatment; the quenching is to heat the stainless steel workpiece to 1000°C and then spray the emulsion, and the process lasts for 0.65 hours.

[0053] Step 5: Temper t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com