High-polymer wireless monitoring tarpaulin and manufacturing process thereof

A production process and polymer technology, applied in textile, load covering, woven fabrics, etc., can solve the problems of tarpaulin being easily cut, easy to fall off, and prone to false alarms, etc., to improve the ability of damage alarm and aging alarm. , Solve the inconsistency of heat shrinkage ratio and improve the effect of surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 provides a winding manufacturing process for a polymer wireless monitoring tarpaulin, the preparation steps of which are:

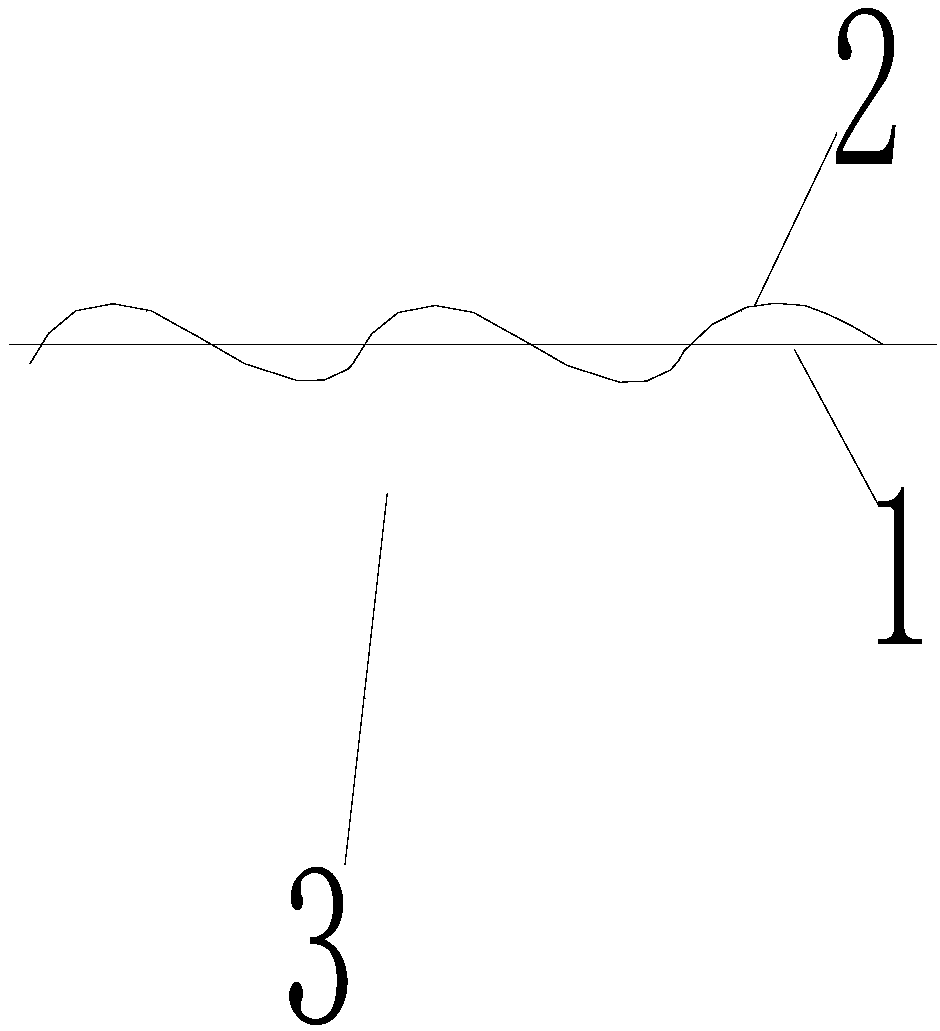

[0042] ① Spinning a polymer conductor, selecting a plurality of metal guide wires to form a metal wire, the outer circumference of each metal guide wire is coated with insulating varnish, multiple metal guide wires are hinged to form a metal wire, and polyester fiber is selected as the inner wire. The inner core 1 is drawn flat, and the inner core is helically wound with the metal wire 2 along the outer peripheral surface for drawing, and the metal wire is coiled on the outer periphery of the inner core to obtain a polymer wire 3 with electrical conductivity.

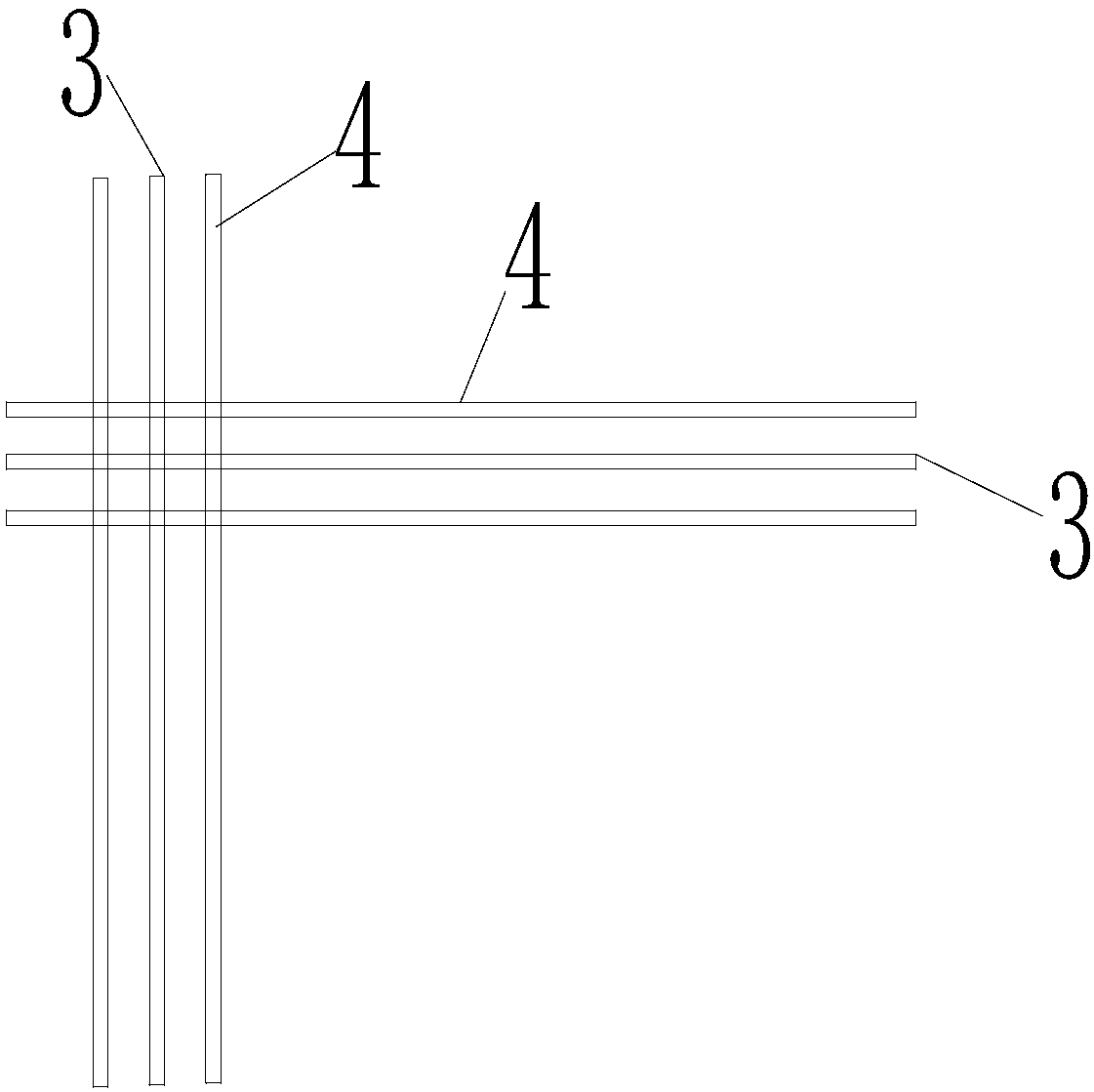

[0043] ② Distribute the yarn, take the polymer guide wire with the same shrinkage rate as the polymer conductor in step ① as the base line, and equip the base line and the polymer wire at equal intervals to the winding machine. The winding machine is distributed at equal interva...

Embodiment 2

[0047] Embodiment 2 provides a winding manufacturing process for a polymer wireless monitoring tarpaulin, the preparation steps of which are:

[0048]① Spinning a polymer conductor, selecting a plurality of metal guide wires to form a metal wire, the outer circumference of each metal guide wire is coated with insulating varnish, and a plurality of metal guide wires are hinged to form a metal wire, and the metal wire 2 is selected as The conductive inner core is coated with fiber yarn on the outer peripheral surface of the metal wire 2 to obtain a polymer wire 3 with electrical conductivity and good adhesion with other fiber yarns;

[0049] ② Distribute the yarn, take the polymer guide wire with the same shrinkage rate as the polymer conductor in step ① as the base line, and equip the base line and the polymer wire at equal intervals to the winding machine. The winding machine is distributed at equal intervals;

[0050] ③ Weaving and warping, lead the base thread and polymer w...

Embodiment 3

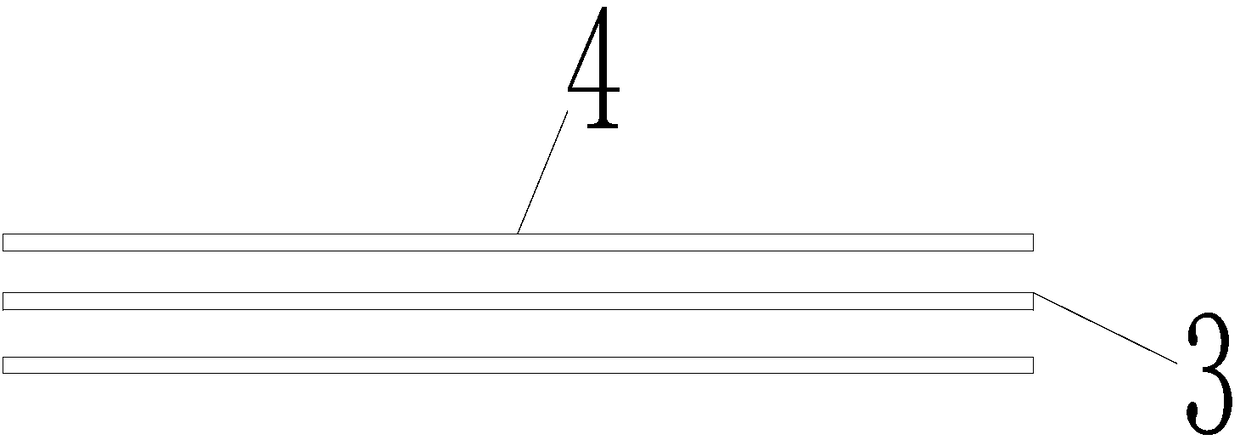

[0053] Embodiment 3 provides a polymer wireless monitoring tarpaulin, including at least one polymer wire for conducting current and a plurality of polymer guide wires, and the polymer wire and the polymer guide wire are interspersed and knitted to form a flat-woven fabric , the polymer wire includes a polyester fiber inner core and a metal wire, the metal wire is helically wound on the outer peripheral surface of the inner core, the shrinkage rate of the metal wire 2 is roughly the same as that of other fibers, and the number of the polymer wire is two, Each polymer wire is bent and extended in an arc shape, and the extension directions of the two polymer wires are perpendicular. Any one or any combination of acyloxyketone and triaryl siloxane, glue the prepared smart tarpaulin, and dry it at a high temperature at 150° -180°, flat woven fabric The bottom surface of the bottom surface is sprayed with coating glue 6 containing ultrafine metal particles, and the upper surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com