35-37 mm artillery body pipe detection traveling device

A technology for artillery barrels and traveling devices, which is applied to special pipes, pipe components, pipes/pipe joints/pipe fittings, etc., and can solve the problems that the rear section cannot move backward, the SMA spring responds slowly, and cannot move at a uniform speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be described in detail below in conjunction with the accompanying drawings.

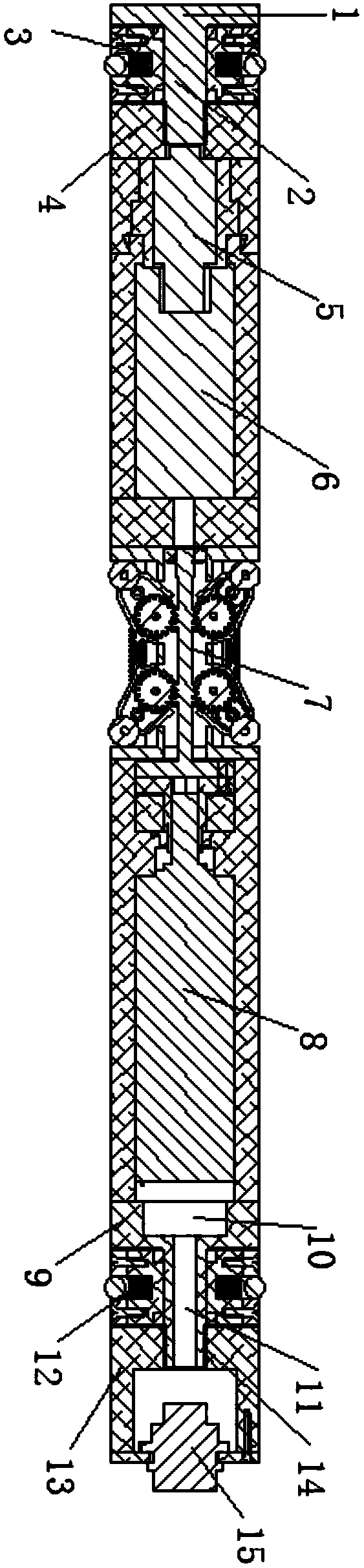

[0068] The structure of the 35mm~37mm gun barrel detection walking device provided by the present invention is as follows: figure 1 As shown, the walking device includes a front guiding centering mechanism, a USB male mechanism 5, a USB female mechanism 6, a walking and driving mechanism and a rear guiding centering mechanism.

[0069] The front guide centering mechanism includes a front connecting bridge, a front guide centering ring 3 and a front axial limiting structure 4 . The front connecting bridge includes a front connecting seat 1 and a front centering shaft 2, the front connecting seat 1 is disc-shaped, and one end of the front centering shaft 2 is fixed on the center of the front connecting seat 1 rear end surface.

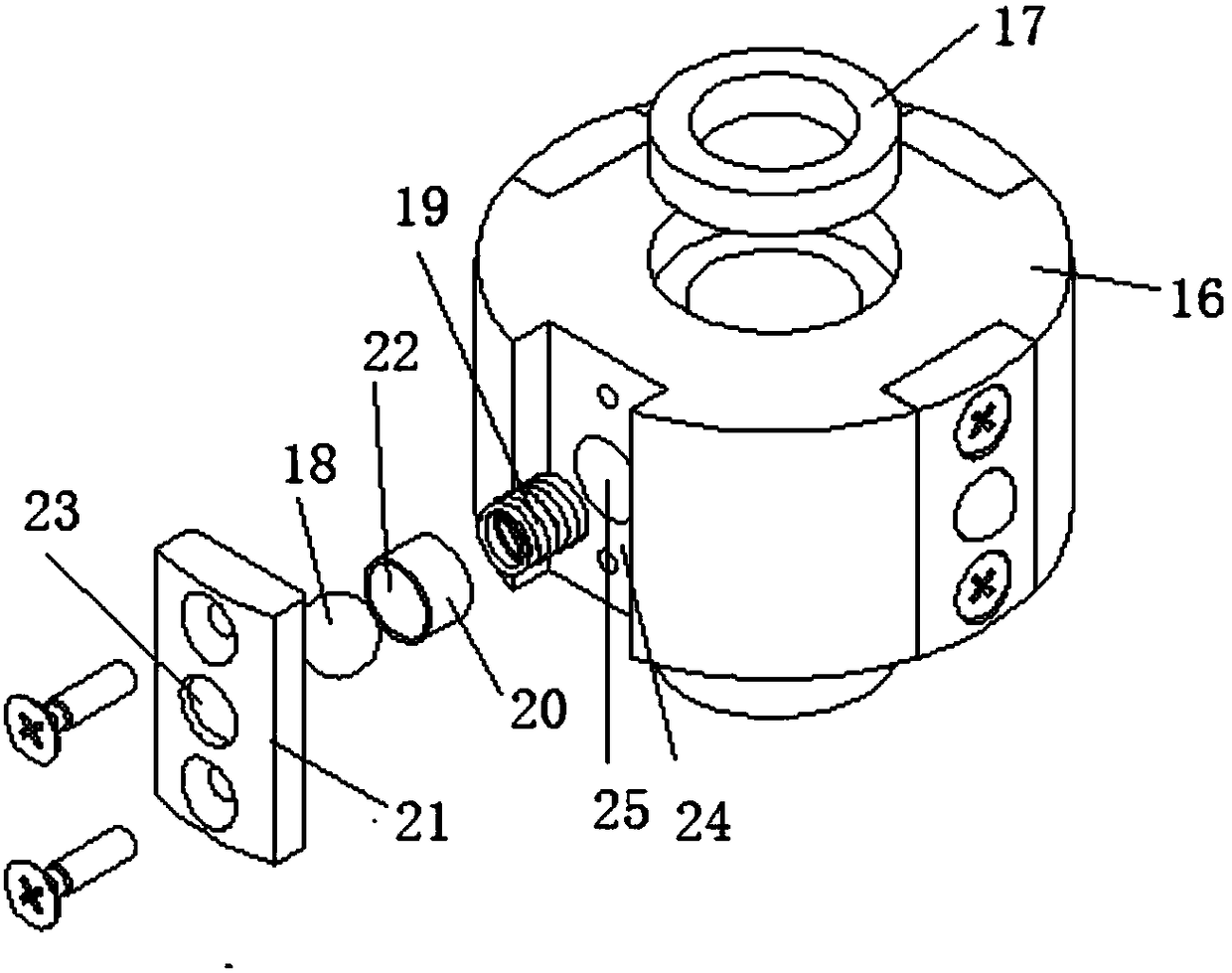

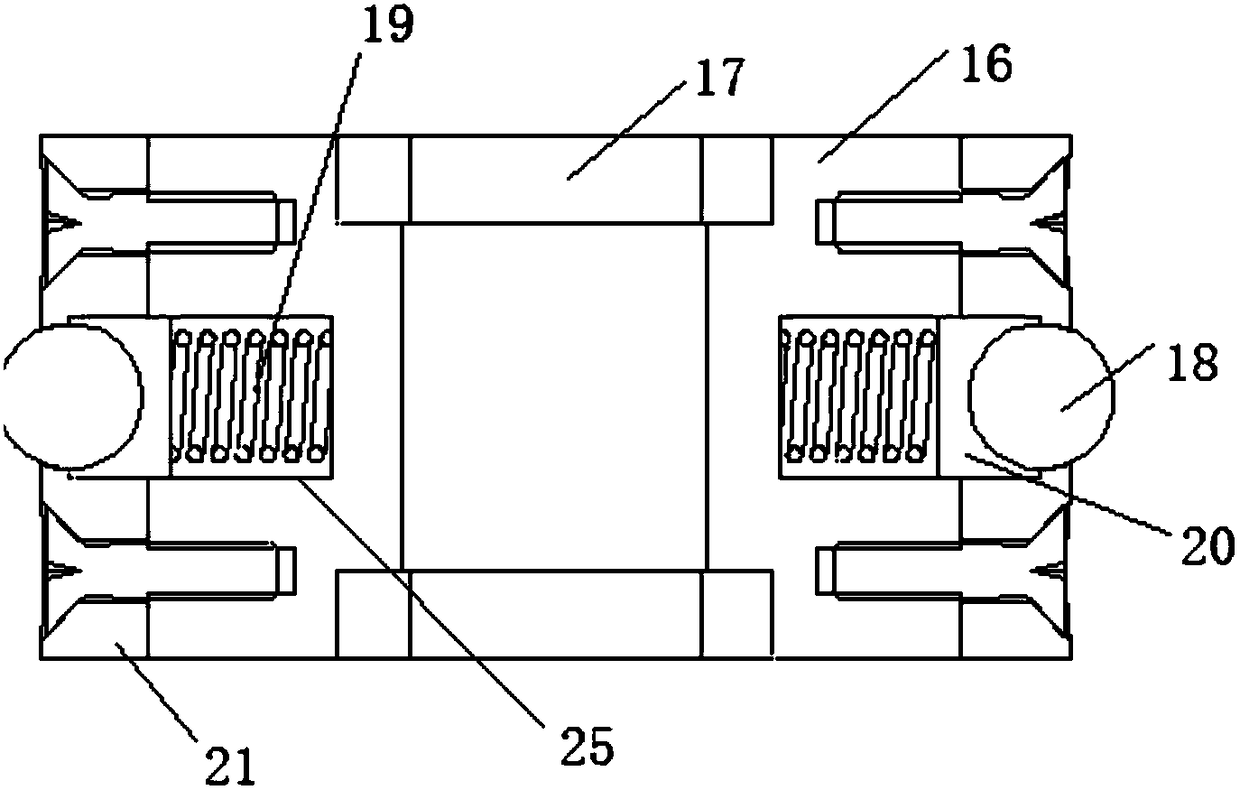

[0070] like figure 2 and image 3 Shown, front guide centering ring 3 comprises front centering ring body 16 and front centering bearing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com